Abstract

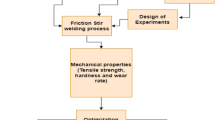

A study of dissimilar friction stir welding of two aerospace aluminum alloys AA2219-T87 and AA7075-T73 is carried out with five friction stir welding (FSW) parameters namely rotational speed, welding speed, tool profile, tilt angle and position of material. The welding was performed as per the L16 Orthogonal array formed by Taguchi mixed factorial design matrix. Taguchi and Grey Relational Analysis was used for single and multiple response optimizations respectively for optimizing tensile strength, yield strength and percentage elongation. Tensile testing was carried out and analysis was done for getting the optimum setting parameters level. Then the results for L16 was ranked and the optimized parameter set was predicted to be A1B1C2D1E1. Further experimental validation weld was performed and the results correlate with the predicted value. A joint efficiency of 71.8% which is even higher than the predicted values was obtained. Microstructural and hardness studies were performed on the validated welds. Fractography was done to understand the mode of failure occurs in the weld region and most fracture occurs with an offset towards AA2219 side. The presence of intermetallic is found in EDS analysis and XRD further validates the intermetallic composition.

Similar content being viewed by others

References

Mishra RS, Ma ZY (2005) Friction stir welding and processing. Mater Sci Eng R Rep 50:1–78. https://doi.org/10.1016/j.mser.2005.07.001

Threadgill PL, Leonard AJ, Shercliff HR, et al (2013) Friction stir welding of aluminium alloys. Inter Mater Reviews 50:49–93. https://doi.org/10.1179/174328009X411136

Debroy T, Bhadeshia HKDH (2010) Friction stir welding of dissimilar alloys – a perspective,Sci Technol Weld Join 15:4:266–270. https://doi.org/10.1179/174329310X12726496072400

Khodir SA, Shibayanagi T (2008) Friction stir welding of dissimilar AA2024 and AA7075 aluminum alloys. Mater Sci Eng B 148:82–87. https://doi.org/10.1016/j.mseb.2007.09.024

Koilraj M, Sundareswaran V, Vijayan S, Rao SRK (2012) Friction stir welding of dissimilar aluminum alloys AA2219 to AA5083 – optimization of process parameters using Taguchi technique. Mater Des 42:1–7. https://doi.org/10.1016/j.matdes.2012.02.016

Guo JF, Chen HC, Sun CN et al (2014) Friction stir welding of dissimilar materials between AA6061 and AA7075 Al alloys effects of process parameters. Mater Des 56:185–192. https://doi.org/10.1016/j.matdes.2013.10.082

Zhang YN, Cao X, Larose S et al (2013) Review of tools for friction stir welding and processing. Can Metall Q:4433. https://doi.org/10.1179/1879139512Y.0000000015

Sadeesh P, M VK, Rajkumar V et al (2014) Studies on friction stir welding of AA 2024 and AA 6061 dissimilar metals. Procedia Eng 75:145–149. https://doi.org/10.1016/j.proeng.2013.11.031

RaviKumar S, SeshagiriRao V, Pranesha RV (2014) Effect of Welding Parameters on Macro and Microstructure of Friction Stir Welded Dissimilar Butt Joints between AA7075-T651 and AA6061-T651 Alloys. Procedia Mater Sci 5:1726–1735. https://doi.org/10.1016/j.mspro.2014.07.362

Saravanan V, Rajakumar S, Banerjee N, Amuthakkannan R (2016) Effect of shoulder diameter to pin diameter ratio on microstructure and mechanical properties of dissimilar friction stir welded AA2024-T6 and AA7075-T6 aluminum alloy joints. Int J Adv Manuf Technol:3637–3645. https://doi.org/10.1007/s00170-016-8695-0

Rajakumar S, Muralidharan C, Balasubramanian V (2011) Influence of friction stir welding process and tool parameters on strength properties of AA7075-T 6 aluminium alloy joints. Mater Des 32:535–549. https://doi.org/10.1016/j.matdes.2010.08.025

Venkateswarlu D, Nageswara P, Mahapatra MM et al (2015) Processing and optimization of dissimilar friction stir welding of AA 2219 and AA 7039 alloys. J Mater Eng Perform 24:4809–4824. https://doi.org/10.1007/s11665-015-1779-4

Khodabakhshi F, Haghshenas M, Sahraeinejad S, et al (2014) Materials Characterization Microstructure-property characterization of a friction-stir welded joint between AA5059 aluminum alloy and high density polyethylene. Mater Charact 98:73–82. https://doi.org/10.1016/j.matchar.2014.10.013

Cavaliere P, De Santis A, Panella F, Squillace A (2009) Effect of welding parameters on mechanical and microstructural properties of dissimilar AA6082-AA2024 joints produced by friction stir welding. Mater Des 30:609–616. https://doi.org/10.1016/j.matdes.2008.05.044

Khodabakhshi F, Simchi A, Kokabi AH, Gerlich AP (2016) Materials Science & Engineering a Similar and dissimilar friction-stir welding of an PM aluminum-matrix hybrid nanocomposite and commercial pure aluminum : microstructure and mechanical properties. Mater Sci Eng A 666:225–237. https://doi.org/10.1016/j.msea.2016.04.078

Arora KS, Pandey S, Schaper M (2010) Effect of process parameters on friction stir welding of aluminum alloy 2219-T87:941–952. https://doi.org/10.1007/s00170-010-2560-3

Priya R, Sarma VS, Rao KP (2009) Transactions of the Indian Institute of Metals Effect of post weld heat treatment on the microstructure and tensile properties of dissimilar friction stir welded AA 2219 and AA 6061 alloys. Trans Indian Inst Metals 62:11–19

Nandan R, DebRoy T, Bhadeshia HKDH (2008) Recent advances in friction-stir welding – process, weldment structure and properties. Prog Mater Sci 53:980–1023

Rafiei R, Shamanian M, Fathi MH, Khodabakhshi F (2018) Dissimilar friction-stir lap-welding of aluminum-magnesium microstructural evolution and mechanical properties. Int J Adv Manuf Technol:3713–3730. https://doi.org/10.1007/s00170-017-0964-z

Rafiei R, Moghaddam AO, Hatami MR, Khodabakhshi F (2017) Microstructural characteristics and mechanical properties of the dissimilar friction-stir butt welds between an Al – Mg alloy and A316L stainless steel. Int J Adv Manuf Technol:2785–2801. https://doi.org/10.1007/s00170-016-9597-x

Khodabakhshi F, Yazdabadi HG, Kokabi AH, Simchi A (2013) Materials Science & Engineering a Friction stir welding of a P / M Al – Al 2 O 3 nanocomposite : microstructure and mechanical properties. Mater Sci Eng A 585:222–232. https://doi.org/10.1016/j.msea.2013.07.062

Xu W, Liu J, Luan G, Dong C (2009) Microstructure and mechanical properties of friction stir welded joints in 2219-T6 aluminum alloy. Mater Des 30:3460–3467. https://doi.org/10.1016/j.matdes.2009.03.018

Lakshminarayanan AK, Malarvizhi S, Balasubramanian V (2011) Developing friction stir welding window for AA2219 aluminium alloy. Trans Non ferrous Met Soc China 21:2339–2347. https://doi.org/10.1016/S1003-6326(11)61018-2

Marthaler DE (2013) An Overview of Mathematical Methods for Numerical Optimization 127:31–54. https://doi.org/10.1007/978-94-007-6664-8

Ju-Long D (1982) Control problems of grey systems. Syst Control Lett 1:288–294. https://doi.org/10.1016/S0167-6911(82)80025-X

Jain VKS, Varghese J, Muthukumaran S (2018) Effect of first and second passes on microstructure and Wear properties of titanium dioxide-reinforced aluminum surface composite via friction stir processing. Arab J Sci Eng. https://doi.org/10.1007/s13369-018-3312-1

Sutton MA, Yang B, Reynolds AP, Taylor R (2002) Microstructural studies of friction stir welds in 2024-T3 aluminum. Mater Sci Eng A 323:160–166. https://doi.org/10.1016/S0921-5093(01)01358-2

Liu HJ, Li JQ, Duan WJ (2013) Friction stir welding characteristics of 2219-T6 aluminum alloy assisted by external non-rotational shoulder. Int J Adv Manuf Technol 64:1685–1694. https://doi.org/10.1007/s00170-012-4132-1

Krishnan KN (2002) On the formation of onion rings in friction stir welds. Mater Sci Eng A 327:246–251. https://doi.org/10.1016/S0921-5093(01)01474-5

Jata KV, Semiatin SL (2000) Continuous dynamic recrystallization during friction stir welding of high strength aluminum alloys. Scr Mater 43:743–749. https://doi.org/10.1016/S1359-6462(00)00480-2

Chen Y, Liu H, Feng J (2006) Friction stir welding characteristics of different heat-treated-state 2219 aluminum alloy plates. Mater Sci Eng A 420:21–25. https://doi.org/10.1016/j.msea.2006.01.029

Malarvizhi S, Balasubramanian V (2011) Effects of welding processes and post-weld aging treatment on fatigue behavior of AA2219 aluminium alloy joints. J Mater Eng Perform 20:359–367. https://doi.org/10.1007/s11665-010-9682-5

Kang J, Feng ZC, Frankel GS et al (2016) Friction stir welding of Al alloy 2219-T8: part I-evolution of precipitates and formation of abnormal Al2Cu agglomerates. Metallurgical and materials transactions a: physical metallurgy and. Mater Sci 47:4553–4565. https://doi.org/10.1007/s11661-016-3648-7

Acknowledgements

The authors gratefully acknowledges the Vikram Sarabhai Space Centre (VSSC - ISRO), Trivandrum for funding the research work with the project, Friction Stir Welding of Aluminum Alloys for aerospace applications under ISRO-RESPOND project scheme and providing the necessary facilities for the research work.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Dinesh Kumar, R., Ilhar Ul Hassan, M.S., Muthukumaran, S. et al. Single and Multi-Response Optimization and Validation of Mechanical Properties in Dissimilar Friction Stir Welded AA2219-T87 and AA7075-T73 Alloys Using T-GRA. Exp Tech 43, 245–259 (2019). https://doi.org/10.1007/s40799-019-00305-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40799-019-00305-3