Abstract

Purpose of Review

Individual tree detection (ITD) methods and technologies for tracking individual forest products through a smart operational supply chain from stump to mill are now available. The purpose of this paper is to (1) review the related literature for audiences not familiar with remote sensing and tracking technologies and (2) to identify knowledge gaps in operational forestry and forest operations research now that these new data and systems are becoming more common.

Recent Findings

Past research has led to successful development of ITD remote sensing methods for detecting individual tree information and radio frequency identification (RFID), branding, and other product tracing methods for individual trees and logs. Blockchain and cryptocurrency that allow independent verification of transactions and work activity recognition based on mobile and wearable sensors can connect the mechanized and motor-manual components of supply chains, bridging gaps in the connectivity of data. However, there is a shortage of research demonstrating use of location-aware tree and product information that spans multiple machines.

Summary

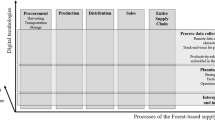

Commercial products and technologies are now available to digitalize forest operations. Research should shift to evaluation of applications that demonstrate use. Areas for improved efficiencies include (1) use of wearable technology to map individual seedlings during planting; (2) optimizing harvesting, skidding and forwarder trails, landings, and decking based on prior knowledge of tree and product information; (3) incorporation of high-resolution, mapped forest product value and treatment cost into harvest planning; (4) improved machine navigation, automation, and robotics based on prior knowledge of stem locations; (5) use of digitalized silvicultural treatments, including microclimate-smart best management practices; and (6) networking of product tracking across multiple, sensorized machines.

Similar content being viewed by others

Introduction

The maturing of remote sensing methods to perform individual tree detection (ITD) [1•, 2], as well as timber harvesting applications of radio frequency identification (RFID) [3•] and other technologies for labeling and tracing individual forest products through the supply chain, introduces new opportunities and challenges for operational forest management. Conventional forest inventory techniques have traditionally focused on use of mean, stand-level estimates of forest attributes in the context of silvicultural and operational planning. Many forest managers, foresters, and researchers are accustomed to working with coarse estimates of stand merchantable volume and stems per hectare, stem piece size distributions, and other average stand conditions as the basis for harvest planning. Although light detection and ranging (lidar) and other remote sensing methods have been used to detect and map data in fine resolution for decades, the resultant products have generally been summarized in conventional ways for the purposes of harvest planning and implementation. However, an aspirational goal for the use of lidar by forest managers and operational foresters has long been the development of functional, ITD mapping that could help foster a new era of high precision, smart, forest operations. An underlying theme and trend in many current regional and global smart and precision forestry initiatives is the integration of ITD and stem characteristics based on lidar point cloud or other remotely sensed data with increasingly sensorized, automated, and data-driven harvest systems that would allow for supply chain level big data analysis and optimization [4, 5•]. This can be seen, for example, in the FPInnovations’ Forestry 4.0 program, which is based on the application of Industry 4.0 digital transformation concepts to forestry, an idea that has gained traction in many countries [6, 7]. This direction and momentum in the operational research community are generally associated with a broad push to improve and advance smart, precision forest management that leverages the merging of big data and Internet-of-Things (IoT) concepts associated with increased forest auomation and robotics [8•, 9•, 10], as well as increasing use of a wide variety of electronic sensors on equipment. Additionally, improving verifiable chain-of-custody criteria associated with sustainable forestry certification programs to curb illegal logging may be a further driver of research into labeling and tracking individual trees and products.

As discussed as recently as 2017 by Talbot et al. [9•], many current precision remote and proximal sensing methods for operational forestry are still experimental and require further research and development. For example, many demonstrated industrial uses of ITD have been limited to single species plantations. However, individual tree stem map products for complex, mixed-species and multi-aged stands over the extent of large forest ownerships based on lidar-derived ITD are now commercially available. As a result, forestry professionals ranging from on-the-ground foresters to academic researchers must increasingly make the challenging and quick transition from very minor, occasional uses or somewhat passive monitoring of lidar’s gradual development over the last few decades to suddenly having massive, rich, high-resolution ITD datasets available for large ownerships. For example, the data shown in Fig. 1 are a small subset of a commercially available lidar-derived ITD product with predicted individual tree location, diameter at breast height (DBH), tree height, species, and crown characteristics for all trees on the main 3,300-ha University of Idaho Experimental Forest. In this context, an important question for many professionals in silviculture and forest operations becomes the following: now that we have these detailed ITD maps and the underlying information, how do we make use of the new data in practical ways to improve stand treatments and harvesting operations to fully implement a smarter and more advanced supply chain? What are the opportunities for shifting research to increasingly operational uses of these data, as opposed to continuing along prior avenues of methodological research, development, and testing?

Subset of commercial 3300-ha ForestView® Individual tree stem map product encompassing over 700 mixed-species stands of varying ages on the University of Idaho Experimental Forest. The underlying ITD product data used to create this figure was developed by Dr. Mark Corrao at Northwest Management, Inc. in Moscow, ID. The horizontal extent of the image shown is approximately 250 m. Tree and product information can be inferred from ITD data (shown below), in which each row corresponds to one dot on the map. The author has color coded dots by species and set dot size proportional to DBH using conventional GIS software for visualization purposes. Color coding is as follows. Red: Douglas-fir (Pseudotsuga menziesii); yellow: ponderosa pine (Pinus ponderosa); dark green: Western red cedar (Thuja plicata); orange: grand fir (Abies grandis); and light green: western larch (Larix occidentalis). Information about general locations of products such as Douglas-fir veneer logs (DFPE1), high-value cedar utility poles (RCU1), Douglas-fir sawlogs (DFS1), and grand fir pulpwood (GFP1) can be inferred from the data graphically, coupled with field observation

In order to address these questions, we reviewed recent literature using Google Scholar with emphasis on publications from the last 5 years and highly cited manuscripts (Fig. 2). Our review was further shaped by experience using ForestView® ITD inventory data (Northwest Management Inc., Moscow ID) in parallel with conventional, stand-based inventory (SBI) data to inform silvicultural treatments and timber management operations on the University of Idaho Experimental Forest for approximately 9 months prior to manuscript submission. Our objectives in the review are (1) to provide a current review of ITD methods based on recent literature, especially for forest operations specialists who are not necessarily experts in remote sensing; (2) to review the use of individual tree-level data in other subject areas in forestry such as growth and yield modeling, silviculture, and forest planning; (3) to provide current, state-of-the-art information on individual forest product tracing using methods like RFID tags placed on trees and logs that can be read by operational equipment attachments on harvesters and processors; (4) to review blockchain and other cryptocurrency methodologies for distributed payment systems that may be paired with individual forest product tracing; and (5) to identify and discuss research gaps in the current literature. In the latter case, our primary emphasis was on identifying and suggesting research on (1) application, rather than development, of ITD and individual product tracing data in operational forestry and (2) systems-level traceability from the individual tree to the mill that spans multiple pieces of equipment.

Remote Sensing Methods for Individual Tree Detection (Airborne, Drone, Terrestrial Lidar)

Both remote and proximal sensing offer opportunities for improving precision in forest operations [9•]. Talbot et al. [9•] distinguish remote sensing from proximal sensing largely based on the platforms used. Remote sensing includes airborne laser scanning (ALS) and generally offers higher spatial coverage but lower spatial resolution while proximal sensing includes terrestrial laser scanning (TLS) and usually offers lower spatial coverage but higher spatial resolution [9•]. Wang et al. [1•] characterizes three approaches to ITD based on ALS: raster-based, point-based, and hybrid approaches combining the two. In raster-based approaches, the information in raster products such as crown height models (CHMs) is used to detect trees based on a variety of segmentation algorithms [1•]. In point-based approaches, the ALS point cloud is used to derive 3D individual tree crown shape directly [1•]. Some newer point-based approaches normalize the ALS point cloud and transfer it to a local voxel space from which trees are detected [1•]. In a hybrid approach, trees are delineated in rasterized data, and the 3D canopy of detected crowns is subsequently modeled from the point cloud data using various clustering and segmentation algorithms [1•]. The authors compared one point-based, two raster-based, and two hybrid approaches and found detection accuracy was affected by canopy structure and point density [1•]. In terms of TLS, Liang et al. [2] describe and evaluate 18 different algorithms for ITD. These approaches have varying degrees of automation, and include raster-, voxel-, and point-based techniques [2]. Individual trees can be identified through different circle and cylinder detection methods and/or voxel and point clustering algorithms [2].

Airborne Lidar and ITD

ALS data has been used to detect individual trees with accuracies of 83.84 [11] to 87% [12]. While evaluating various approaches to detecting individual trees in different crown classes, Wang et al. [1•] found that most methods provided detection rates greater than 85% for dominant trees and greater than 70% for codominant trees. Individual tree-based features derived from ALS data have been shown to improve the accuracy of predicted attributes such as mean height, mean DBH, and volume [11]. Most notably, volume was estimated with an RMSE of 20.32% using both individual tree-based features and point height metrics, compared to an RMSE of 25.41% using point height metrics only [11]. ALS data has been used to estimate forest above-ground biomass (AGB) through a process that involves detecting individual tree crowns and then calculating tree density, tree height, individual crown length, and mean height of forest layers [13]. AGB was calculated with an RMSE of 17.1% at the forest plot level using lidar-derived individual tree data, compared to an RMSE of 31.1% using a traditional regression model approach incorporating both field measurements and lidar point cloud metrics [13]. Individual tree data from ALS has also been used to estimate individual tree crown width and crown volume [14] as well as to optimize tree removal and inform thinning prescriptions in order to reduce crown fire potential within stands [15]. Luo et al. [12] developed a method of estimating individual tree crown base height directly from ALS data without the need for field measurements with an RMSE of 1.62 m, which has applications for tree growth and health monitoring as well as for ecosystem and wildfire modeling. Recent work has utilized ALS data to model more detailed information such as branch attributes in order to estimate branch angle, length, and volume among individual trees [16].

Terrestrial Lidar

Because it provides a different, below-canopy perspective, terrestrial lidar is also being used to quantify and map individual tree data [17]. Trochta et al. [17] developed an open-source application called 3D Forest which is capable of extracting DBH, tree positions and heights, stem curves, and tree planar projections from TLS data. The application can also describe detailed crown parameters such as crown base height, crown height, and crown volume and surface area [17]. Liang et al. [2] found that TLS-based approaches to ITD can estimate DBH and stem curves with accuracies of 1–2 cm. After extracting trees, wood and leaf points are often separated using classical machine learning and computer vision algorithms [18•]. Quantitative structure modeling (QSM) algorithms can then be used to estimate wood volume and model tree morphology [18•] and to segment and classify the physiological age of annual shoots from tree skeletons [19]. Recent QSM approaches have investigated the potential for deep learning to delineate tree stems and branches [20] as well as to detect structural properties of branches [21]. Calders et al. [18•] summarize a variety of applications of TLS ITD data in the measurement of forest attributes, including calculating DBH, estimating wood volume, and incorporating crown structure information into traditional allometric models. In the context of operational forestry, these novel measurement techniques may provide more detailed information on log geometry and quality in addition to offering a better understanding of growth and changes in biomass [18•]. The structural and spatial information derived from TLS data can also provide insights on the effects of various silvicultural practices [18•].

Drone Lidar

High pulse density drone lidar is able to incorporate wider scan angle than airborne (by virtue of being at lower elevation) and is being used for high-resolution mapping of localized forest structure in order to calibrate space-borne lidar [22•]. Whereas acquisition of terrestrial lidar can be relatively slow, drone-based high density lidar can span large areas quickly and still retain pulse density up to several thousand points per square meter [22•]. ITD from drone lidar has been used to identify priority areas for wildfire prevention [23] as well as to detect invasive species when fused with imagery data [24]. Drone lidar is also being used to delineate individual trees and predict DBH and species in order to estimate tree volume at the plot, stand, and forest levels without the need for field data for calibration [25]. Recent work has evaluated the potential for under-canopy drone lidar to extract stems and tree heights in order to calculate individual tree volume with a level of accuracy similar to TLS [26].

Structure from Motion

The Structure from Motion (SfM) methodology uses low-cost imaging platforms to extract forest biophysical parameters for both aerial and terrestrial applications [27•]. SfM applied to unmanned aerial vehicle (UAV) image data has been used in individual tree approaches to detect trees, classify species, and measure tree heights [27•]. Both UAV lidar and SfM were recently used to accurately measure individual seedling height down to a 1-m threshold [28]. Most terrestrial applications of SfM have focused on modeling individual trees, primarily to estimate tree positions and heights, DBH, and stem curvature [27•] and smartphone-based SfM has been used to estimate DBH and stem volume [29]. SfM is also used in assessing and monitoring forest condition by classifying tree health [27•].

ITD from Forestry Equipment

As mentioned above, there is a strong effort to increase digitalization of the forestry supply chain broadly in the context of Forestry 4.0 concepts [30•]. The increasing use of big data and AI in smart forestry is associated with the drive to automate thinning and harvesting through robotics [31]. Use of individual tree metrics like stem volume improves estimates of operational performance, productivity, and costs [32] and may also provide the basis for equipment positioning and navigation using simultaneous localization and mapping (SLAM) [5•, 33]. For example, Miettinen et al. [34] describe the use of machine vision and 3D scanning to measure trees during harvesting operations, in order to optimize felling and increase harvester automation. A combination of 3D laser scanning and SLAM was used to measure standing tree stems prior to felling in order to estimate crown base height, taper, sweep, trunk dimensions, branches, and lean [34]. Cameras attached to an ATV have been used to measure trees and estimate structure from a distance through motion vision while cameras on the harvester head were used to measure length and thickness of processed stems [34]. Based on similar methodology, SLAM has also been considered a general forest inventory technique, as well as for equipment positioning and navigation [35]. An underlying concept in SLAM is that a stem map is constructed on-the-fly based on equipment-mounted sensor data. The map becomes more complete as equipment works. This working map of the stand environment is recorded in memory, and the resulting map then forms the basis for subsequent, autonomous machine guidance, which could occur independently of GNSS-based navigation [36].

ITD and Chain-of-Custody

Many forest legal and sustainability certification programs include product chain-of-custody documentation [37]. In addition to broad interest in the operational forestry community to advance smart and precision forest operations, the development of verifiable chain-of-custody is a key motivator for developing and testing individual forest product labeling and tracing systems. A natural outcome of increasing interest in chain-of-custody is the desire to track products from their actual, exact place of origin. In the context of forest operations, the place of origin is ultimately the individual tree’s verifiable geographic coordinates in the woods. This could be the location of a residual stump, or a verifiable individual stem that was removed, as evident in multitemporal satellite imagery, aerial photography, or lidar acquisitions. Chain-of-custody technologies include log branding, bar coding, use of tracer paints, RFID, and chemical or biological fingerprinting [38] as well the recent use of DNA-based tracking [39]. Coupled with remote sensing, cloud computing, and big data, fiber sourcing and supply chain technologies are helping to improve sustainable forestry as originally envisioned and intended [40].

Use of RFID to Store Information with Individual Standing Trees

At present, several systems for tree and timber marking are available in the market, varying from simple paint or chalk to systems capable of storing a certain amount of information retrievable with automatic systems [41]. Among the different alternatives for data transmission, RFID technology is regarded as the best solution for a number of reasons: painted codes or logos may wear out due to weather exposition over time [42], and, compared to manual systems, automatically readable systems avoid human errors and drastically reduce recording time [43]. RFID also allows reading in any light conditions, without requiring a precise line of sight and even when tags are hidden by mud, dirt, or resin [44]. Thanks to its performance, RFID is currently deployed in a wide range of industrial sectors, ranging from manufacturing to logistics. In agriculture, RFID technology is already a standard for cattle identification [45] and provides promising applications in nursery management [46] and potted plants distribution [47]. Additionally, the identification of living plants in open field, generally permanent crops, is raising an increasing interest as it would facilitate several precision agriculture practices, such as the selective and optimized application of chemicals [48]. The implementation of RFID in forestry shares similar challenges of tag survivability and reading capacity related to open air deployment. However, in agriculture the position of plants, tags and reading devices can be planned in order to maximize the efficiency of the whole system, while in forest conditions, such planning has a much higher degree of uncertainty, which may lead to poor results. For this reason, among the possible operating frequencies for RFID, ultra high frequency (UHF) is regarded as the most suitable, as it allows the longest reading ranges [49•]. Marczewski et al. [50] tested the suitability of passive and active UHF RFID tags to mark and retrieve trees in a natural forest combining GPS positioning and RFID identification at long range (>10 m). Results with passive tags were unsatisfactory due to (1) the dense undergrowth vegetation, which reduced the effective range of tags, and (2) the unpredictable mutual position of the tags and the reader, which further compromised the capacity to detect a return signal. Given the operating conditions, active RFID tags performed better due to their stronger signal and higher reading range, but their higher unitary cost and battery duration should be carefully considered when planning each specific application.

For the requirements of forestry and timber supply chains, passive and disposable UHF RIFD tags are regarded as the best solution [51, 52]. These types of RFID tags may be deployed for a wide range of services beyond single-tree retrieval. For instance, they can be used to associate digital information with standing trees for recreational purposes, forest management and protection, or timber production [10]. In these applications, long-range readability is less critical as trees can also be marked with visual systems (e.g., color spray), allowing the operators to approach the tree and identify the tag with manual readers. In a similar application, commercial UHF RFID tags proved capable of withstanding the harsh climatic conditions of an Alpine forest and retained their operative capacity for 2 years [3•]. In this environment, resin emission and tree growth proved to be the most challenging factors as the former can attack the plastic layers protecting lighter tag models, while the latter can break the hard case of “heavy duty” tags fixed with screws on the trunk. The study suggests that long-term tagging of high-value trees (e.g., nesting trees for protected species) should rely on large tags with strong protective cases fixed to the trunk with plastic screws. Metal screws should be avoided due to the possible damages they may cause to the sawmilling equipment. The screw should also be long enough to leave a gap between the tag and the bark in order to avoid damages due to tree growth.

When marking trees selected to be felled in forest operations, simpler RFID tag models with large transponder and low unitary cost (< 0.40 €/0.48 $) are preferred. These can be easily stapled to bark and provide the best reading performance, which may enable both manual and automatic tag detection (e.g., with a processor head). This last application was tested by Pichler et al. [53•] in a study comparing the technical feasibility and costs of a digital forest inventory with traditional manual-based forest inventory. Simple UHF RFID tags were used to connect information derived from UAV-aerial images and TLS scanning to each tree. The whole digital system proved technically mature, yet its overall cost resulted in 1.55 € per marked tree against 0.36 € for the traditional inventory and marking system. In the former, the main cost factor was the high density of TLS plots, which aimed to directly scan every trunk rather than improve statistical inventory (as currently used in commercial applications). The high-quality data was used to generate a digital model of each trunk and relate it to the value of the local timber assortments, returning cutting instructions that were linked to each tree and transferred to the processor with the RFID tags, maximizing the timber value recovery. In motor-manual felling operations followed by whole-tree cable yarder extraction, the simple RFID tags used in the previous study were able to withstand hauling operations with a survival rate of 97%, proving to be a reliable tool for data transfer among the different steps of the timber supply chain [44]. RFID tag components (transponder and chip) are currently made with metal protected by a plastic case, and since tags attached to the logs would enter the stream of sawmill residues, this could reduce acceptability from the industry. A possible solution to this issue is printing RFID tags directly on renewable materials [54]. This technique was also tested to produce RFID tags with dual frequency (UHF and near field contact, NFC) [55], which could further reduce the investment costs of the system: foresters and chainsaw operators could deploy common smartphones with NFC functions to read the tags and relate them to the database, while the UHF potential would still allow long distance and machine identification.

Individual Tree Data in Growth and Yield

Growth functions that predict stem diameter or basal area increment over time based on individual tree attributes and the surrounding, competitive environment have long been used as the basis for stand growth simulators deployed widely for forest management [56, 57]. Recent models represent growth in structurally complex stands [58]. Multitemporal SfM and multitemporal lidar are being used to quantify growth [59]. However, relatively few simulators leverage height increment, crown surface area, and other canopy metrics that are more easily inferred from remotely sensed data collected from aircraft or UAVs, rather than DBH increment. This is largely a function of DBH being the common measurement conventionally available in manual, ground-based stand inventory. While non-spatial individual tree competition indices appear to predict growth generally as well as spatial indices in naturally regenerated mixed-species stands [60], multitemporal lidar provides the data to quickly parameterize new kinds of models that fully leverage individual crown metrics, which are closely related to the photosynthetic capacity of trees, in order to forecast individual stem volume growth in biologically meaningful ways. A good example of a physiological, process-based model that represents individual tree and stand growth as a function of tree crown characteristics over time is the Amorphys model [61••]. Though developed prior to the maturing of current, lidar-derived ITD analysis, models conceptually similar to the approach described in Valentine and Mäkelä [61••] may become extremely important in the future as multitemporal lidar increasingly becomes used as the basis for modeling stand growth in ways that support climate smart silvicultural and operational planning.

Individual Tree Data in Silviculture and Forest Planning

ITD methods discussed in the preceding sections vary in their ability to detect trees in the different forest canopy classes (dominant, codominant, intermediate, suppressed) that form the basis of stand development and silvicultural treatments [1•]. Accurate estimation of tree location, height, and crown structure have been proposed as a useful application of SfM data in order to define treatments for individual tree selection systems used in Ponderosa pine (Pinus ponderosa Lawson & C. Lawson) stands in Colorado, USA [62]. Recently, preliminary methods for optimizing stand prescriptions for individual tree and group selection and clearcut systems in ways that account for the spatial distribution of the stand based on analysis of ITD data have been presented [63]. Similarly, Wing et al. [64] developed a method to generate group selection treatment options utilizing ALS-derived stem map data in order to meet various management objectives. These methods are promising, and modeling and optimization show that accounting for individual tree characteristics during thinning is economically beneficial [65•, 66•]. Large databases are available to quantify fire effects of individual trees to support planning of prescribed fire and to assist with post-fire evaluation [67].

Direct Log Measurements Using Encoders in Harvesters and Processors

Harvester and processor heads measure stem diameter with sensors in the delimbing knives or feed rollers that use either three points of measurement or the average of two perpendicular measurements to determine log diameter at multiple points along the stem [68]. As rollers feed the stem, length is determined using a digital measuring wheel mounted directly on the head and intermediate points are interpolated based on stem taper. A range of algorithms can then be used to estimate timber volume based on log length and diameter measurements [69]. Stem swell associated with branch whorls or stem defect is accounted for via algorithms in the onboard computer. Harvester-derived estimates of stem defects can be used in bucking simulations designed to predict product recovery [70]. While measurements are precise, harvesting and processing head measurements require regular monitoring and calibration [68]. Harvester measurements of tree length, diameter, volume, and location have been used as reference data for ALS-based predictions of forest inventory attributes [71]. Because harvesters do not measure the top crown section, they provide total log length but not total tree height [72]. Thus, recent work has attempted to develop improved models for estimating individual tree heights from harvester data in order to facilitate harvester-based inventory and analytics through integration with traditional inventory and lidar data [72]. Advanced characteristics of forest products, such as wood stiffness and related properties of logs determined from acoustic time-of-flight measurements, can increasingly be integrated into harvesting or processing heads and used to inform processor bucking decisions in real-time [73].

Reading Individual Log Identification on Harvester or Processor Heads

Research and industrial development are increasingly focusing on the potential of data provided by sensors installed on forest machines, and particularly the harvester heads that fell and process trees into commercial timber assortments in cut-to-length (CTL) harvesting systems. In addition to the valuable information provided by the standard encoders, several sensors have been tested on processor heads to measure timber density [74] or a combination of quality factors (timber density, knottiness, crosscut section defects) to return a quality index value [75••] as shown in Fig. 3. The information generated is meant to be used to optimize transportation, purchase, and industrial processing of timber in the supply chain. To maximize the value of the information generated, a number of solutions for log identification and data transfer have been proposed and evaluated experimentally or developed into commercial products [41]. Most solutions rely on robust and cost-effective visual systems, such as barcode-like marks printed with spray nozzles installed on the chainsaw bar of the processor head [76] or with punching systems. The latter is a device that consists of 12 hammer brands that punch wood with a combination of marks that represent an alphanumeric code [77]. In both cases, an optical reader installed on the sawmill feeding line acquires images that are converted to a unique ID code for each log, making it possible to retrieve any information provided by the processor head and stored in a shared database. These solutions are robust and cost-effective since they do not rely on disposable tags, yet they require a line of sight and proper illumination to be detected.

A RFID tags on log ends for stump-to-mill traceability tests in the Italian Alps (Trento), B sensorized processor head described in Sandak et al. [75••] featuring log-grading sensors (i.e., timber density, quantity of knots, presence of rot), an RFID reader designed to detect the ID of trees to be processed and an RFID tagger deployed to mark each log and associate it with the quality data generated

RFID and Biometric Log Identification on Equipment Attachments

An interesting alternative is the use of RFID, which had been successfully deployed on prototype processor heads in the frame of two European projects. The first system was equipped with a device for marking logs with a special RFID tag composed of wood composites. This resulted in a neutral material for the pulp industry [78]. The second prototype was designed so that the processor head could read RFID tags attached to the incoming stems (e.g., in cable yarding operations), assess timber quality with sensors, and relate the relevant data to each log with a new RFID tag automatically attached to the crosscut section [75••]. The advantage of this solution is allowing successful log ID detection in poor visibility conditions as well as providing a mechanism for efficient and fast bulk reading of whole log trucks, particularly the guaranteed detection of all tagged logs [79]. Biometric fingerprinting of forest products is another promising technique that utilizes scanning and image analysis to identify patterns in the cross-sectional ends of logs for improved individual product tracing. Two- and three-dimensional log biometric fingerprinting is used operationally in advanced sawmills, and has shown very promising results for accuracies up to 100% using methods similar to those applied in the context of fingerprint and iris recognition in controlled studies [80].

Sustainable Sourcing, Cryptocurrency, and the Blockchain

To fully address legal and sustainability certification and chain-of-custody compliance, digitization of traceability requires networking methodologies that ultimately connect information flow from the forest to the mill. Additionally, a visionary goal in smart and precision forestry systems is the realization of improved inventory monitoring. For example, in the preferred case, mill owners should be able to monitor and evaluate the current product volumes remaining to be harvested, current inventory volumes in each sorted log deck at the landings in active timber sale areas, and specific products in transit. A motivating example is to achieve the level of information availability and inventory control that occurs with modern, online purchasing through large suppliers like Amazon, and parcel delivery management. Among a range of possible solutions to achieve this level of verifiability in remote, forested areas, the blockchain technology that forms the basis of cryptocurrency transactions has become a frontrunner. Blockchain is a shared database ledger system that stores all transactions in encrypted packets that provide a verifiable record over time [81]. Blockchain-based cryptocurrencies such as Bitcoin or Ethereum can form the basis for Evidence, Verifiability, and Enforcement (EVE) systems using smart contracts [82]. Blockchain can now be deployed off-grid using mesh radio networks such as goTenna (Brooklyn, NY, USA), the LoRa network [83], or coupled with the Blockstream or Swarm low-cost data satellite networks [84] that have been designed to provide local to global IoT networking solutions.

Activity Recognition Based on Location

As harvested logs are skidded or forwarded and handled by the different pieces of equipment used in cut-to-length, whole-tree, shovel-logging, steep slope, or traditional cable systems, coupling RFID or other technologies with equipment activity recognition based on global navigation satellite system (GNSS) devices deployed on either equipment cabs or attachment heads provide a mechanism for maintaining a record of individual log movements from stump to landing and onto loaded trucks. Location based on GNSS can define the productive work of logging equipment, including skyline carriages on cable operations and boom movements [85,86,87]. GNSS-based location can also define safe work zones on the fly in dynamic environments and quantify complex, location-based functions of multiple moving resources to improve situational awareness and safety [88, 89]. Forest canopy and topography differentially affect GNSS accuracy and radio network communication quality due to multipath error and radio signal interference in real-time data networks [90]. The majority of research to date has evaluated a small number of pieces of equipment [85]. However, Wempe et al. [88] has also demonstrated simultaneous monitoring of multiple pieces of equipment and rigging crew workers in near real-time with movements recorded at a rate of one location per second using GNSS-enabled radios. Differentially corrected GNSS positioning of the harvester head can now also be used to measure individual tree geographic positions with sub-meter accuracy [91•]. Positioning the harvester head, when coupled with StanForD files, permits growth rate and taper estimation for forest inventory from harvesters. However, because the resulting inventory data collected in this way is only applicable for post-harvest reconstruction of stand attributes [92•], it is more likely that future ITD mapping and inventory control systems will rely on prior ITD from one of the available remote sensing methods which foster pre-treatment planning and smart equipment guidance.

Activity Recognition Based on Wearable and Mobile Device Sensors

The data collected in real-time by accelerometers and other microelectromechanical sensors in consumer-grade smartphones, smartwatches, or other mobile and IoT devices can be used to develop accurate models predicting activities in motor-manual operations, such as felling trees [93•]. This concept has further been adapted to smartwatches to model choker-setter and chaser operations (setting and releasing chokers) on conventional cable logging operations [94]. The appeal of using common phones and watches to quantify motor-manual logging and forestry support services such as tree planting and thinning is that once predictive models are encoded in phone or watch apps, predicted activities can then be logged for complete work shifts indefinitely, creating a rich array of data to support subsequent analyses. The concept underlying this approach with integrated activity recognition modeling and remote networking to provide a consistent, real-time summary of simultaneous supply chain components and operational activities at active sites in the woods is shown in Fig. 4. Methods exist to render data independent of sensor orientation [93•] or the device location or position on handheld equipment using a multi-layer perceptron [95•, 96]. Machine learning methods such as random forests and artificial neural networks, as well as deep learning, are useful methods for automating artificial intelligence based either on videography [97] or accelerometer data [94].

Conceptual mobile application framework for maintaining individual motor-manual worker and equipment activity recognition information coupled with individual tree and product data in a networked, relational database at the jobsite. Tables are associated with the equipment movements of each individually identified tree or product as they are transferred among equipment. Smartphone illustration credit: Ryer Becker, Ph.D., University of Idaho

In the context of individual product tracing, a key benefit of these device-based methods for monitoring manual activities is that most smartphones and watches are also now readily capable of scanning RFID and NFC tags using a variety of available apps that can be automated to store these data. For example, since 2020, consumer smartphones have been used regularly to read and write information to RFID stickers associated with all log truck load tickets in harvesting operations on the University of Idaho Experimental Forest. The same approach can be used to scan individual tree RFID records during manual felling activities, and existing, phone-based models [93•] can easily log GNSS coordinates associated with tree felling events. Another important benefit of phone- and watch-based activity recognition is that activity and product tracing data logged in this way can readily be transferred to shared databases on equipment using either mesh radios, or the emerging data satellite networks [84, 88, 90].

An important consideration for use of wearable and mobile device sensor data in human activity recognition related to quantifying work productivity and the tracing of individual trees and forest products is the use of personal information collected by these devices [8•]. The protection and security of personal information is often an afterthought in the design of wearable and IoT devices [98]. This is particularly true because wearable sensor data often is not covered by legal and privacy protections associated with conventional medical data [99].

Knowledge Gaps and Emerging Opportunities

Based on our review of available methods and technologies for carrying individual tree and product data through the supply chain from stump to mill, we find there are currently few remaining barriers inhibiting their adoption. The component building blocks needed for complete systems that locate trees and monitor forest products with high precision using RFID, branding or other techniques have largely been established through continued research, as have methods to share data through remote networks that support shared databases, blockchain, or other techniques for tracing and verifying products. Spatial ITD lidar products are now being marketed commercially for forest management purposes in mixed-species stands. However, our review reveals that because new ITD products and tracing methods are just now emerging, there is comparatively little research demonstrating how use of ITD products can improve silvicultural treatments and operational efficiencies in practice. After almost three decades of research and development in industry, academia, and federal agencies, operational forestry seems unprepared to make use of new ITD products now that they are available. As methods for ITD and product detection and monitoring continue to mature and be refined, a significant shift is needed from development and evaluation of measurement and remote sensing methodologies in the forest inventory context to the evaluation of applied methods for using individual tree and product information in technology-informed silvicultural treatments, and planning and implementation of operations. To establish an agenda for this exciting area of research, we propose the following priorities to help advance use of individual tree and product information.

Mapping Individual Seedling Locations During Planting Operations

As operational forestry incorporates use of ITD data throughout the life cycle of stand management, a current gap appears to exist in the consistent, accurate mapping of young, regenerating stands. For example, adjacent stands to the northeast and southwest of those identified in Fig. 5 include young, planted seedlings and saplings that are not indicated as stems in the commercial ITD product. This presents a knowledge gap for managers in a period that often involves the largest economic investment (costs) associated with site preparation and planting, especially in intensively managed and even-aged stands. Human activity recognition coupled with GNSS may provide an opportunity to map seedlings during planting operations based on smartphones, smartwatches, or real-time GNSS in order to generate maps that can subsequently be incorporated into lidar-based ITD inventory programs over time.

The boundaries of two stands managed historically on the University of Idaho Experimental Forest are not well correlated with species composition. Within each stand, topographic influences heavily affect the distribution of Douglas-fir (red) and grand fir (orange) on more eastern aspects and ponderosa pine (yellow) on more western aspects. Based on this knowledge, landings (DFL1, PPL1, etc.) are being planned to minimize skidding and handling of sorted products, rather than using a central landing and then subsequently sorting logs into decks. Horizontal extent of clipped image is approximately 345 m

Optimizing Skidding and Forwarding, Processing, and Decking

Depending on the details of silvicultural prescriptions, it may be preferable to remove more young or old trees, trees of a particular species, or to minimize trail-related impacts to the residual stand entirely. Prior, complete knowledge of stem spatial pattern within the stand makes it possible to optimize routes that function within desired constraints such as minimizing removal of one or more species, minimizing stems removed solely to support the trail system, or location of trails in areas of low soil productivity.

In regions with mixed-species stands and many product sorts, ITD maps introduce the possibility of minimizing overall product handling and distance traveled from stump to deck (Fig. 5). By identifying species or product category locations at their point of origin through spatial analysis, it may be possible to tailor log landings to minimize the timing and skidding or forwarding direction of individual sorts. This approach can build on recent work using GIS to optimize precision planning of skid trails and winching [5•, 100], and to increase the sustainability of forwarding [101]. Rather than feeding all wood to one or more general landings and sorting products to decks from that point, ITD makes it possible to define smart landings. In regions where feller-bunchers are used, prior knowledge of preferred bunch characteristics and landing direction to minimize overall product handling seems feasible. Increasingly, the use of ITD data is associated with a shift in thinking to address the question: how can we optimize systems of equipment, or systems of motor-manual and mechanized equipment together in ways that are based on location-aware analytics, rather than optimizing individual equipment independently for mean handling of average stem volume and piece size in ways that have been largely non-spatial?

Incorporating High-Resolution Forest Product Value and Treatment Cost into Harvest Planning

Prior knowledge of individual forest product locations corresponds directly to both resource value and operational treatment cost within the treated stand. ITD data facilitates within-stand planning that may affect not only spatial arrangement of skidding or forwarding trails, landings, and product sort locations, but also the timing of harvest treatments. This is particularly true in mixed-species forests where the value of different products may vary considerably and the preferred timing of harvesting, processing, and delivering products to one or another mill destination may vary based on weather, market demand, or value. For example, in the Inland Northwest United States, products in the same stands range from very low-value pulpwood to cedar utility poles that are particularly high value. Using ITD data, knowledge of within-stand value may directly improve operational budget planning over time scales from weeks to years based on the sequence and timing of resource extraction in ways that augment and enhance conventional, stand-level harvest planning.

Digitalizing Advanced Silvicultural Treatments

Along with forest operations, silviculture stands to grow in new and exciting ways due to the availability of ITD data. For example, advanced treatments based on actual, high-resolution individual tree growth environments can be designed to reflect the alternative spacing requirements of different target species within stands. In uneven-aged, continuous cover, or any non-clearcut silvicultural systems, ITD data affords the opportunity to inform the selection of leave trees by applying spatial queries to a digital inventory list rather than an assumed distribution of stem sizes and locations. As evident in Fig. 1, mean, stand-level estimates of species volume can represent substantial variability in product type and location within harvest units. Using digitized ITD inventory data, candidate leave trees can be pre-determined based on location, DBH, height, crown ratio, species, and target spacing in ways that have not previously been possible. In this regard, one area that is particularly interesting is the possibility of accounting for topography and light interception associated with forest microclimates to inform both “smart” silvicultural treatments and operational best management practices simultaneously. For example, during marginal seasons when temperatures fluctuate above and below freezing in temperate regions, maintaining partial canopy south or west of road and trail systems may provide shade that extends available operating periods by maintaining frozen road or trail conditions. In many ways, the presence of detailed, tree-level spatial data provides the opportunity to automate or intelligently augment many of the decision processes that field foresters and harvester operators undertake when selecting trees for removal. Individual tree information forms the basis for most underlying silvicultural theory, yet detailed, quantitative silvicultural prescriptions are often complex and challenging to translate and implement in the field, particularly in uneven-aged and mixed-species stands or to meet multiple resource objectives when implementing forest management plans. Rather than estimating the spacing of leave trees in the field when marking trees individually, spatial point pattern analysis can be used to digitally select and refine stand density management treatments over thousands or millions of trees in ways that incorporate the effects of slope, aspect, topography, stand adjacency, and soil productivity within harvest units to best optimize growth, the regeneration environment, and other objectives. Furthermore, in regions where “operator choice” or “operator select” prescriptions are given to operators to implement thinning treatments, spatial queries of ITD data provide an opportunity to provide advanced, preliminary selections of candidate, individual trees to inform these procedures in more advanced ways.

Machine Navigation for Improved Automation and Robotics

Research on SLAM methods to help automate equipment guidance and robotics assume that stem locations are unknown at the start of operations (hence localization and mapping). However, adoption of ITD remote sensing and the subsequent existence of digital forest maps prior to operations simplifies navigation algorithm processing for equipment guidance, automation, and robotics. The localization step in equipment guidance becomes a much simpler matter of matching patterns of detected trees (via equipment-mounted lidar, machine vision, or other sensors) to an existing map that improves on the position accuracy or becomes an improved substitute for GNSS-based location of the machine and attachment head. Instead of relying on remote, mobile satellites, the forest itself becomes a powerful constellation of fixed referenced points that remain in place for the length of stand rotation. Rather than a source of canopy interference and multipath error, we need to shift our paradigm to recognizing that these trees are valuable geolocation points for precision guidance.

Sharing Product Locations from Stump to Mill

Methods exist for integrating RFID into the harvester head in cut-to-length systems. After the felling step, an RFID nail inserted into a tree at breast height could remain in the lower log and be monitored through the supply chain using RFID readers mounted on equipment. However, any secondary logs or products bucked from the stem become separated and of unknown origin. In order to trace these other products, the harvester head must either fingerprint the cross-section of upper stem logs in order to assign their geographic coordinates and tree number of origin or have the capability to insert additional RFID tags or other tracing elements. Thus, automated application of bar codes, QR codes, RFID, or other low-cost identification via the harvester head is an important area of development. In whole-tree systems, the head of a processor working at the landing must have the capability to both scan incoming parent information on whole trees and also apply that information to child logs as the stem is bucked, ultimately using the system described in this paper two or more times during processing and subsequent handling of the logs. For complete automation and digitization, both the skidder or forwarder and log loader should also have the ability to scan and record product identification as materials are handled in the supply chain, such that ultimately the current locations of all products on the jobsite are known and accounted for at all times.

Managing Big Data in Remote Environments

As ITD and individual forest product data are transferred among machines using RFID or other product tracing methods and distributed, verifiable payment methods such as blockchain technology extend to the edge of networking in the forest, associated supply chain analytics must increasingly manage big data. Research on developing functional machine-to-machine (M2M) internet capability in remote forests, as well as research connecting data from the forest jobsite back to the mill or operational headquarters in real-time, is needed [8•]. There has been little research truly leveraging data across the full spectrum of the individual tree and product supply chain [6]. Use of artificial intelligence (AI) to improve operations or supply chain efficiencies in real-time in response to mill needs, market factors, and other considerations linked between harvest operations and product marketing will require massive data storage, processing power, and network bandwidth in areas that currently often lack any internet or cellular data coverage. Canadian systems are the most advanced utilizing forestry equipment computing and data strategies that function independently of proprietary machine software, and associated work has evaluated M2M internet options [6]. Systems that reduce the dimensionality of data at low local levels in IoT processing can help alleviate networking bandwidth needs in remote environments [8•]. However, further research is needed to empirically test the reliability of various networking options in the field in order to identify system capabilities and limitations in real-world environments.

Conclusion

As new ITD data products for forest managers become available, researchers and managers will need to shift the weight of research and development effort from prediction algorithms, evaluation, and validation of remote sensing products to the operational application and use of ITD data in silviculture and operations. This is particularly true in the design of high-resolution silvicultural prescriptions, optimal harvest unit layout, harvesting, skidding, and processing to fully utilize prior knowledge of individually stem-mapped stands, and even the locations of individual products within trees.

Based on our review, airborne, drone, and terrestrial lidar and SfM remote sensing techniques, as well as other sensor and photogrammetry methods not addressed in this review, provide useful data for informing ITD. In practice, these techniques are also used concurrently to inform ITD products. For example, terrestrial lidar, drone lidar, or both may be used concurrently in the collection of field plot data that is then utilized to improve segmentation models for ALS predictions over large spatial extents. RFID scanning has been demonstrated successfully as a method to maintain readable data on single trees over time in ways that could be accessed by scanners mounted on equipment or UAVs. RFID has also been used to record information about individual log products using a scanner mounted on the processor head. Branding and biometric fingerprinting are feasible technologies for product tracing. Cryptocurrency payment and ledger systems that utilize the blockchain provide a distributed, verifiable mechanism that may supplement and strengthen chain-of-custody verification for the purposes of forest certification. Human and machine activity recognition modeling, coupled with RFID or other scanning and identification methods, provide a framework for tracing individual forest products from a source tree location through logging systems and to the mill. In short, all the components of a smart, ITD, and product tracing system exist.

Given that ITD products and methodologies for equipment-based scanning and tracing of individual products exist, we have identified several opportunities for research utilizing these technologies to help optimize the digital supply chain. These include studies demonstrating and evaluating the following: (1) mapping of individual seedling locations during planting operations; (2) optimizing skidding and forwarding, processing, and decking in ways that incorporate ITD product information; (3) incorporating high-resolution forest product value and treatment costs into harvest planning; (4) digitalizing advanced silvicultural treatments based on current and future ITD information; (5) improving machine location accuracy and navigation to increase automation and robotics; (6) sharing of product information from M2M and stump to mill; and (7) managing the big data associated with ITD and individual product information in remote environments. Each of these research areas contributes to an agenda that can help managers and researchers utilize newly available ITD and individual product data to continue advancing the digitalization of forest operations.

References

Papers of particular interest, published recently, have been highlighted as: • Of importance •• Of major importance

• Wang Y, Hyyppä J, Liang X, Kaartinen H, Yu X, Lindberg E, et al. International benchmarking of the individual tree detection methods for modeling 3-D canopy structure for silviculture and forest ecology using airborne laser scanning. IEEE Trans Geosci Remote Sens. 2016;54:5011–27. https://doi.org/10.1109/TGRS.2016.2543225This paper summarizes the accuracy of different ITD methods across a wide range of conditions.

Liang X, Hyyppä J, Kaartinen H, Lehtomäki M, Pyörälä J, Pfeifer N, et al. International benchmarking of terrestrial laser scanning approaches for forest inventories. ISPRS J Photogramm Remote Sens. 2018;144:137–79. https://doi.org/10.1016/j.isprsjprs.2018.06.021.

• Picchi G. Marking standing trees with RFID tags. Forests. 2020;11:150. https://doi.org/10.3390/f11020150This paper provides an evaluation of the performance of RFID tags after being attached to trees and exposed to weather over time.

Feng Y, Audy J-F. Forestry 4.0: A framework for the forest supply chain toward Industry 4.0. Gest Prod. 2020;27:e5677. https://doi.org/10.1590/0104-530X5677-20.

Picchio R, Proto AR, Civitarese V, Di Marzio N, Latterini F. Recent contributions of some fields of the electronics in development of forest operations technologies. Electronics. 2019;8:1465. https://doi.org/10.3390/electronics8121465This paper provides a nice, summary review of a variety of current electronic sensors that are being used in forest operations.

Gingras J-F, Charette F. FPInnovations’ Forestry 4.0 initiative. Proceedings of the 2017 Council on Forest Engineering Annual Meeting [Internet]. Bangor, ME, USA; 2017 [cited 2021 Dec 5]. Available: http://cofe.org/files/2017_Proceedings/FPInnovations%20Gingras%20Charette%20Forestry%204.0%20for%20COFE%202017.pdf.

Brown M, Ghaffariyan MR, Berry M, Acuna M, Strandgard M, Mitchell R. The progression of forest operations technology and innovation. Aust For. 2020;83:1–3. https://doi.org/10.1080/00049158.2020.1723044.

Keefe RF, Wempe AM, Becker RM, Zimbelman EG, Nagler ES, Gilbert SL, et al. Positioning methods and the use of location and activity data in forests. Forests. 2019;10:458. https://doi.org/10.3390/f10050458This paper provides a general summary of real-time positioning and wearable and mobile technologies to support individual tree and product big data applications in smart and precision forestry.

Talbot B, Pierzchała M, Astrup R. Applications of remote and proximal sensing for improved precision in forest operations. Croat J For Eng. 2017;38:327–36 This paper provides a summary of remote and proximal sensing technologies and reviews current applications for improving precision in forest operations.

Torresan C, Benito Garzón M, O’Grady M, Robson TM, Picchi G, Panzacchi P, et al. A new generation of sensors and monitoring tools to support climate-smart forestry practices. Can J For Res [Internet]. 2021 [cited 2021 May 3]; https://doi.org/10.1139/cjfr-2020-0295.

Hyyppä J, Yu X, Hyyppä H, Vastaranta M, Holopainen M, Kukko A, et al. Advances in forest inventory using airborne laser scanning. Remote Sens. 2012;4:1190–207. https://doi.org/10.3390/rs4051190.

Luo L, Zhai Q, Su Y, Ma Q, Kelly M, Guo Q. Simple method for direct crown base height estimation of individual conifer trees using airborne LiDAR data. Opt Express. 2018;26:A562–78. https://doi.org/10.1364/OE.26.00A562.

Ferraz A, Saatchi S, Mallet C, Jacquemoud S, Gonçalves G, Silva CA, et al. Airborne lidar estimation of aboveground forest biomass in the absence of field inventory. Remote Sens. 2016;8:653. https://doi.org/10.3390/rs8080653.

Kato A, Moskal LM, Schiess P, Swanson ME, Calhoun D, Stuetzle W. Capturing tree crown formation through implicit surface reconstruction using airborne lidar data. Remote Sens Environ. 2009;113:1148–62. https://doi.org/10.1016/j.rse.2009.02.010.

Contreras MA, Chung W. Developing a computerized approach for optimizing individual tree removal to efficiently reduce crown fire potential. For Ecol Manag. 2013;289:219–33. https://doi.org/10.1016/j.foreco.2012.09.038.

du Toit F, Coops NC, Goodbody TRH, Stoehr M, El-Kassaby YA. Deriving internal crown geometric features of Douglas-fir from airborne laser scanning in a realized-gain trial. For Int J For Res. 2021;94:442–54. https://doi.org/10.1093/forestry/cpaa046.

Trochta J, Krůček M, Vrška T, Král K. 3D Forest: An application for descriptions of three-dimensional forest structures using terrestrial LiDAR. PLoS One. 2017;12:e0176871. https://doi.org/10.1371/journal.pone.0176871.

Calders K, Adams J, Armston J, Bartholomeus H, Bauwens S, Bentley LP, et al. Terrestrial laser scanning in forest ecology: Expanding the horizon. Remote Sens Environ. 2020;251:112102. https://doi.org/10.1016/j.rse.2020.112102This paper describes recent advances in TLS technology and data processing and discusses a variety of applications of TLS ITD data in forest measurement and management.

Lecigne B, Delagrange S, Taugourdeau O. Annual shoot segmentation and physiological age classification from TLS data in trees with acrotonic growth. Forests. 2021;12:391. https://doi.org/10.3390/f12040391.

Xi Z, Hopkinson C, Chasmer L. Filtering stems and branches from terrestrial laser scanning point clouds using deep 3-D fully convolutional networks. Remote Sens. 2018;10:1215. https://doi.org/10.3390/rs10081215.

Halupka K, Garnavi R, Moore S. Deep semantic instance segmentation of tree-like structures using synthetic data. Proceedings of the 2019 IEEE Winter Conference on Applications of Computer Vision (WACV). Waikoloa, HI, USA: IEEE; 2019. p. 1713–22. https://doi.org/10.1109/WACV.2019.00187.

Kellner JR, Armston J, Birrer M, Cushman KC, Duncanson L, Eck C, et al. New opportunities for forest remote sensing through ultra-high-density drone lidar. Surv Geophys. 2019;40:959–77. https://doi.org/10.1007/s10712-019-09529-9This paper provides a thorough description of the technical considerations for drone remote sensing, presents a case study illustrating the potential for drone lidar, and summarizes promising opportunities for drone-based forest remote sensing.

Fernández-Álvarez M, Armesto J, Picos J. LiDAR-based wildfire prevention in WUI: The automatic detection, measurement and evaluation of forest fuels. Forests. 2019;10:148. https://doi.org/10.3390/f10020148.

Dash JP, Watt MS, Paul TSH, Morgenroth J, Pearse GD. Early detection of invasive exotic trees using UAV and manned aircraft multispectral and LiDAR data. Remote Sensing. 2019;11:1812. https://doi.org/10.3390/rs11151812.

Puliti S, Breidenbach J, Astrup R. Estimation of forest growing stock volume with UAV laser scanning data: Can it be done without field data? Remote Sens. 2020;12:1245. https://doi.org/10.3390/rs12081245.

Hyyppä E, Hyyppä J, Hakala T, Kukko A, Wulder MA, White JC, et al. Under-canopy UAV laser scanning for accurate forest field measurements. ISPRS J Photogramm Remote Sens. 2020;164:41–60. https://doi.org/10.1016/j.isprsjprs.2020.03.021.

Iglhaut J, Cabo C, Puliti S, Piermattei L, O’Connor J, Rosette J. Structure from Motion photogrammetry in forestry: A review. Curr For Rep. 2019;5:155–68. https://doi.org/10.1007/s40725-019-00094-3This paper presents the technical principals of SfM and reviews both the aerial and terrestrial applications of SfM in forestry.

Hartley RJL, Leonardo EM, Massam P, Watt MS, Estarija HJ, Wright L, et al. An assessment of high-density UAV point clouds for the measurement of young forestry trials. Remote Sens. 2020;12:4039. https://doi.org/10.3390/rs12244039.

Marzulli MI, Raumonen P, Greco R, Persia M, Tartarino P. Estimating tree stem diameters and volume from smartphone photogrammetric point clouds. For Int J For Res. 2020;93:411–29. https://doi.org/10.1093/forestry/cpz067.

Müller F, Jaeger D, Hanewinkel M. Digitization in wood supply – A review on how Industry 4.0 will change the forest value chain. Comput Electron Agric. 2019;162:206–18. https://doi.org/10.1016/j.compag.2019.04.002This paper provides a useful recent summary of Forestry 4.0 concepts and their implications for operational forestry supply chains.

Oliveira LFP, Moreira AP, Silva MF. Advances in forest robotics: A state-of-the-art survey. Robotics. 2021;10:53. https://doi.org/10.3390/robotics10020053.

Rodrigues CK, da Silva LE, Pereira ALN, Sampietro JA. Effect of individual tree volume on operational performance of harvester processor. Floresta. 2019;49:345–52. https://doi.org/10.5380/rf.v49i2.58233.

Billingsley J, Visala A, Dunn M. Robotics in agriculture and forestry. In: Siciliano B, Khatib O, editors. Springer Handbook of Robotics. Berlin: Springer-Verlag; 2008. p. 1065–77.

Miettinen M, Kulovesi J, Kalmari J, Visala A. New measurement concept for forest harvester head. In: Howard A, Iagnemma K, Kelly A, editors. Field and service robotics. Berlin: Springer; 2010. p. 35–44.

Tang J, Chen Y, Kukko A, Kaartinen H, Jaakkola A, Khoramshahi E, et al. SLAM-aided stem mapping for forest inventory with small-footprint mobile LiDAR. Forests. 2015;6:4588–606. https://doi.org/10.3390/f6124390.

Nevalainen P, Li Q, Melkas T, Riekki K, Westerlund T, Heikkonen J. Navigation and mapping in forest environment using sparse point clouds. Remote Sens. 2020;12:4088. https://doi.org/10.3390/rs12244088.

Paluš H, Parobek J, Vlosky RP, Motik D, Oblak L, Jošt M, et al. The status of chain-of-custody certification in the countries of Central and South Europe. Eur J Wood Prod. 2018;76:699–710. https://doi.org/10.1007/s00107-017-1261-0.

Dykstra DP, Kuru G, Taylor R, Nussbaum R, Magrath W, Story J. Technologies for wood tracking: Verifying and monitoring the chain of custody and legal compliance in the timber industry [Internet]. Washington, DC, USA: World Bank/WWF Alliance for Forest Conservation and Sustainable Use; 2002 p. 88. Available: http://awsassets.panda.org/downloads/woodtrackingreportfinal.pdf.

Dormontt E, Lowe A. Developing DNA-based chain of custody systems for legally-sourced teak [Internet]. Canberra, Australia: Australian Centre for International Agricultural Research; 2019 p. 28. Report No.: FR2019-98. Available: https://aciar.gov.au/sites/default/files/project-page-docs/final_report_fst-2016-025.pdf.

Taylor R, Davis C, Brandt J, Parker M, Stäuble T, Said Z. The rise of big data and supporting technologies in keeping watch on the world’s forests. Int For Rev. 2020;22:129–41. https://doi.org/10.1505/146554820829523880.

Picchi G, Sandak J, Grigolato S, Panzacchi P, Tognetti R. Smart harvest operations and timber processing for improved forest management. In: Tognetti R, Smith M, Panzacchi P, editors. Climate-Smart Forestry in Mountain Regions. Springer; 2021.

Mohamed N, Garoot AH, Hazza ZM. A case study on impacts of RFID adoption in tree inventory management. Proceedings of the 2009 2nd IEEE International Conference on Computer Science and Information Technology. Beijing: IEEE; 2009. p. 624–8. https://doi.org/10.1109/ICCSIT.2009.5234874.

Kaakkurivaara N. Possibilities of using barcode and RFID technology in Thai timber industry. Maejo Int J Sci Technol. 2019;13:29–41.

Picchi G, Kühmaier M, Díaz Marqués J de D. Survival test of RFID UHF tags in timber harvesting operations. Croat J For Eng 2015;36:165–174.

Ruiz-Garcia L, Lunadei L. The role of RFID in agriculture: Applications, limitations and challenges. Comput Electron Agric. 2011;79:42–50. https://doi.org/10.1016/j.compag.2011.08.010.

Quino J, Maja JM, Robbins J, Fernandez RT, Owen JS, Chappell M. RFID and drones: The next generation of plant inventory. AgriEngineering. 2021;3:168–81. https://doi.org/10.3390/agriengineering3020011.

Barge P, Gay P, Piccarolo P, Tortia C. RFID tracking of potted plants from nursery to distribution. Proceedings of the International Conference Ragusa SHWA2010 [Internet]. Ragusa Ibla, Italy; 2010 [cited 2021 May 3]. p. 541–8. Available: http://www.ragusashwa.it/CD_2010/lavori/TOPIC5/orale/RFIDtrackingplants[1].pdf.

Zhai C, Landers A, Zhang B. An RFID-based solution for monitoring sprayer movement in an orchard/vineyard. Precis Agric. 2018;19:477–96. https://doi.org/10.1007/s11119-017-9531-8.

Björk A, Erlandsson M, Häkli J, Jaakkola K, Nilsson Å, Nummila K, et al. Monitoring environmental performance of the forestry supply chain using RFID. Comput Ind. 2011;62:830–41. https://doi.org/10.1016/j.compind.2011.08.001This early paper provides a good conceptual overview of the potential for using RFID in the supply chain.

Marczewski T, Ma Y, Sun W. Evaluation of RFID tags to permanently mark trees in natural populations. Front Plant Sci. 2016;7:1342. https://doi.org/10.3389/fpls.2016.01342.

Tzoulis IK, Andreopoulou ZS, Voulgaridis E. Wood tracking information systems to confront illegal logging. J Agric Informatics. 2014;5:9–17. https://doi.org/10.17700/jai.2014.5.1.130.

Kaakkurivaara T, Kaakkurivaara N. Comparison of radio frequency identification tag housings in a tropical forestry work environment. Aust For. 2019;82:181–8. https://doi.org/10.1080/00049158.2019.1678797.

Pichler G, Poveda Lopez JA, Picchi G, Nolan E, Kastner M, Stampfer K, et al. Comparison of remote sensing based RFID and standard tree marking for timber harvesting. Comput Electron Agric. 2017;140:214–26. https://doi.org/10.1016/j.compag.2017.05.030This paper provides a joint example of 3D stand mapping coupled with RFID marking of individual trees for product tracing.

Virtanen J, Virkki J, Ukkonen L, Sydänheimo L. Inkjet-printed UHF RFID tags on renewable materials. Adv Internet Things. 2012;2:23699. https://doi.org/10.4236/ait.2012.24010.

Le V, Lemmer U, Mackensen E. Analysis of miniaturized printed flexible RFID/NFC antennas using different carrier substrates. IEEE J Radio Freq Identif. 2020;4:428–37. https://doi.org/10.1109/JRFID.2020.3001336.

Stage AR. Prognosis model for stand development. Intermountain Forest & Range Experiment Station, Forest Service, U.S. Department of Agriculture; 1973.

Wykoff WR. A basal area increment model for individual conifers in the northern Rocky Mountains. For Sci. 1990;36:1077–104. https://doi.org/10.1093/forestscience/36.4.1077.

Hamidi SK, Weiskittel A, Bayat M, Fallah A. Development of individual tree growth and yield model across multiple contrasting species using nonparametric and parametric methods in the Hyrcanian forests of northern Iran. Eur J For Res. 2021;140:421–34. https://doi.org/10.1007/s10342-020-01340-1.

Guerra-Hernández J, González-Ferreiro E, Monleón VJ, Faias SP, Tomé M, Díaz-Varela RA. Use of multi-temporal UAV-derived imagery for estimating individual tree growth in Pinus pinea stands. Forests. 2017;8:300. https://doi.org/10.3390/f8080300.

Kuehne C, Weiskittel AR, Waskiewicz J. Comparing performance of contrasting distance-independent and distance-dependent competition metrics in predicting individual tree diameter increment and survival within structurally-heterogeneous, mixed-species forests of Northeastern United States. For Ecol Manag. 2019;433:205–16. https://doi.org/10.1016/j.foreco.2018.11.002.

Valentine HT, Mäkelä A. Bridging process-based and empirical approaches to modeling tree growth. Tree Physiol. 2005;25:769–79. https://doi.org/10.1093/treephys/25.7.769This paper describes a methodology for incorporating individual tree crown data into biologically meaningful prediction of stem growth based on individual tree crown characteristics.

Creasy MB, Tinkham WT, Hoffman CM, Vogeler JC. Potential for individual tree monitoring in ponderosa pine dominated forests using unmanned aerial system structure from motion point clouds. Can J For Res. 2021;51:1093–105. https://doi.org/10.1139/cjfr-2020-0433.

Packalen P, Pukkala T, Pascual A. Combining spatial and economic criteria in tree-level harvest planning. For Ecosyst. 2020;7:18. https://doi.org/10.1186/s40663-020-00234-3.

Wing BM, Boston K, Ritchie MW. A technique for implementing group selection treatments with multiple objectives using an airborne lidar-derived stem map in a heuristic environment. For Sci. 2019;65:211–22. https://doi.org/10.1093/forsci/fxy050.

West T, Sessions J, Strimbu BM. Heuristic optimization of thinning individual Douglas-fir. Forests. 2021;12:280. https://doi.org/10.3390/f12030280Provides useful analysis of the economic benefit of incorporating individual tree information into operational thinning treatments based on heuristics.

Fransson P, Franklin O, Lindroos O, Nilsson U, Brännström Å. A simulation-based approach to a near-optimal thinning strategy: Allowing harvesting times to be determined for individual trees. Can J For Res. 2020;50:320–31. https://doi.org/10.1139/cjfr-2019-0053This paper provides a useful example of incorporating individual tree information into operational harvest implementation.

Cansler CA, Hood SM, Varner JM, van Mantgem PJ, Agne MC, Andrus RA, et al. The Fire and Tree Mortality Database, for empirical modeling of individual tree mortality after fire. Sci Data. 2020;7:194. https://doi.org/10.1038/s41597-020-0522-7.

Nordström M, Hemmingsson J. Measure up! - A Skogforsk guide to harvester measurement [Internet]. Palmér CH, editor. Uppsala, Sweden: Skogforsk; 2018 [cited 2021 May 4]. Available: https://www.skogforsk.se:443/english/products-and-events/other/measure-up%2D%2D-a-skogforsk-guide-to-harvester-measurement/.

Löwe R, Sedmíková M, Natov P, Jankovský M, Hejcmanová P, Dvořák J. Differences in timber volume estimates using various algorithms available in the control and information systems of harvesters. Forests. 2019;10:388. https://doi.org/10.3390/f10050388.

Barth A, Möller JJ, Wilhelmsson L, Arlinger J, Hedberg R, Söderman U. A Swedish case study on the prediction of detailed product recovery from individual stem profiles based on airborne laser scanning. Ann For Sci. 2015;72:47–56. https://doi.org/10.1007/s13595-014-0400-6.

Saukkola A, Melkas T, Riekki K, Sirparanta S, Peuhkurinen J, Holopainen M, et al. Predicting forest inventory attributes using airborne laser scanning, aerial imagery, and harvester data. Remote Sens. 2019;11:797. https://doi.org/10.3390/rs11070797.

Shan C, Bi H, Watt D, Li Y, Strandgard M, Ghaffariyan MR. A new model for predicting the total tree height for stems cut-to-length by harvesters in Pinus radiata plantations. J For Res. 2021;32:21–41. https://doi.org/10.1007/s11676-019-01078-6.

Carter P, Wang X, Ross RJ. Field application of processor head acoustic technology in forest harvest operations. Proceedings of the 18th International Nondestructive Testing and Evaluation of Wood Symposium [Internet]. Madison, WI, USA: US Forest Service - Forest Products Laboratory; 2013 [cited 2021 May 4]. Available: https://www.fpl.fs.fed.us/documnts/pdf2013/fpl_2013_carter001.pdf.

Walsh D, Strandgard M, Carter P. Evaluation of the Hitman PH330 acoustic assessment system for harvesters. Scand J For Res. 2014;29:593–602. https://doi.org/10.1080/02827581.2014.953198.

Sandak J, Sandak A, Marrazza S, Picchi G. Development of a sensorized timber processor head prototype – part 1: Sensors description and hardware integration. Croat J For Eng. 2019;40:25–37 This paper provides a real-world example of using multiple sensors on the processor head to support individual product measurements and tracing.

Möller B, Wikander J, Hellgren M. A field-tested log traceability system. For Prod J. 2011;61:466–72. https://doi.org/10.13073/0015-7473-61.6.466.

OTMETKA [Internet]. OTMETKA. [cited 2021 May 3]. Available: https://otmetka.com/.

Häkli J, Sirkka A, Jaakkola K, Puntanen V, Nummila K. Challenges and possibilities of RFID in the forest industry. In: Reaz MBI, editor. Radio Frequency Identification from System to Applications [Internet]. Rijeka, Croatia: InTechOpen; 2013 [cited 2021 May 3]. p. 301–24. https://doi.org/10.5772/54205.

Kaul C. Auto-ID in the timber supply chain - identifying single logs using RFID tags. Proceedings of FORMEC 2010 - Forest Engineering: Meeting the Needs of the Society and the Environment [Internet]. Padova, Italy; 2010 [cited 2021 May 3]. Available: https://citeseerx.ist.psu.edu/viewdoc/download?doi=10.1.1.1067.3429&rep=rep1&type=pdf.