Abstract

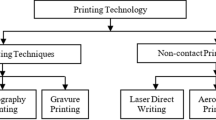

Non-contact ink writing techniques are a newly developed three-dimensional printing technology to fabricate customized and flexible electronic devices, while dramatically reducing chemical waste and lowering manufacturing costs. However, the use of non-contact ink writing technologies for fabricating electronics is still limited due to printing quality. To develop an electronic device with high performance, conductive lines should be printed with high controllability and excellent uniformity. Under such circumstances, many traditional optimization methods have been proposed to improve the printing quality. However, as the non-contact ink writing process is very sensitive to the system drifts and random variations, in situ process monitoring and online optimization technologies to optimize the printed line quality are in demand for practical printing. In this paper, we describe the processes of non-contact ink writing techniques based on inkjet printing (IJP) and aerosol jet printing (AJP). The key influencing factors in the non-contact ink writing processes are also discussed based on the three main printing stages. Then we analyze the advantages and disadvantages of the IJP and AJP techniques and review the state of art in quality optimization and precise control techniques that can be adopted in non-contact ink writing process. Additionally, to further develop a non-contact ink writing system, the major challenges and limitations of the current printing quality optimization technologies are also highlighted in this paper.

Reprinted with permission from ref. [50]. Copyright (2008) American Chemical Society

Adapted with permission from ref. [51]. Copyright (2015) American Chemical Society

Similar content being viewed by others

References

Han, T.-H., Lee, Y., Choi, M.-R., Woo, S.-H., Bae, S.-H., et al. (2012). Extremely efficient flexible organic light-emitting diodes with modified graphene anode. Nature Photonics,6(2), 105.

Zhu, H., Xiao, Z., Liu, D., Li, Y., Weadock, N. J., et al. (2013). Biodegradable transparent substrates for flexible organic-light-emitting diodes. Energy and Environmental Science,6(7), 2105–2111.

Krebs, F. C. (2009). Fabrication and processing of polymer solar cells: a review of printing and coating techniques. Solar Energy Materials and Solar Cells,93(4), 394–412.

Thompson, B. C., & Fréchet, J. M. (2008). Polymer–fullerene composite solar cells. Angewandte Chemie International Edition,47(1), 58–77.

Jung, M., Kim, J., Noh, J., Lim, N., Lim, C., et al. (2010). All-printed and roll-to-roll-printable 13.56-MHz-operated 1-bit RF tag on plastic foils. IEEE Transactions on Electron Devices,57(3), 571–580.

Zheng, Y., He, Z., Gao, Y., & Liu, J. (2013). Direct desktop printed-circuits-on-paper flexible electronics. Scientific reports,3, 1786.

Kim, T.-I., Hwan Jung, Y., Chung, H.-J., Jun Yu, K., Ahmed, N., et al. (2013). Deterministic assembly of releasable single crystal silicon-metal oxide field-effect devices formed from bulk wafers. Applied Physics Letters,102(18), 182104.

Clemens, W., Fix, W., Ficker, J., Knobloch, A., & Ullmann, A. (2004). From polymer transistors toward printed electronics. Journal of Materials Research,19(7), 1963–1973.

Yan, H., Chen, Z., Zheng, Y., Newman, C., Quinn, J. R., et al. (2009). A high-mobility electron-transporting polymer for printed transistors. Nature,457(7230), 679.

Chang, W.-Y., Fang, T.-H., Lin, H.-J., Shen, Y.-T., & Lin, Y.-C. (2009). A large area flexible array sensors using screen printing technology. Journal of display technology,5(6), 178–183.

Khan, S., Lorenzelli, L., & Dahiya, R. (2014). Bendable piezoresistive sensors by screen printing MWCNT/PDMS composites on flexible substrates. 10th Conference on Ph. D. Research in Microelectronics and Electronics, France.

Qi, Q., Zhang, T., Yu, Q., Wang, R., Zeng, Y., et al. (2008). Properties of humidity sensing ZnO nanorods-base sensor fabricated by screen-printing. Sensors and Actuators B: Chemical,133(2), 638–643.

Kim, K., Kim, J., Kim, B., & Ko, S. (2018). Fabrication of microfluidic structure based biosensor using roll-to-roll gravure printing. International Journal of Precision Engineering and Manufacturing-Green Technology,5(3), 369–374.

Jeong, T.-G., Seo, Y.-H., Kim, S., Song, J., Ko, S.-L., et al. (2014). Roll to roll air-floating oven drying process design and analysis for printed electronics. International Journal of Precision Engineering and Manufacturing,15(7), 1303–1310.

Chu, W.-S., Kim, C.-S., Lee, H.-T., Choi, J.-O., Park, J.-I., et al. (2014). Hybrid manufacturing in micro/nano scale: a review. International Journal of Precision Engineering and Manufacturing-Green Technology,1(1), 75–92.

Pease, R. F., & Chou, S. Y. (2008). Lithography and other patterning techniques for future electronics. Proceedings of the IEEE,96(2), 248–270.

Søndergaard, R. R., Hösel, M., & Krebs, F. C. (2013). Roll-to-roll fabrication of large area functional organic materials. Journal of Polymer Science Part B: Polymer Physics,51(1), 16–34.

Nathan, A., Ahnood, A., Cole, M. T., Lee, S., Suzuki, Y., et al. (2012). Flexible electronics: the next ubiquitous platform. Proceedings of the IEEE,100, 1486–1517.

Yoon, H.-S., Lee, J.-Y., Kim, H.-S., Kim, M.-S., Kim, E.-S., et al. (2014). A comparison of energy consumption in bulk forming, subtractive, and additive processes: Review and case study. International Journal of Precision Engineering and Manufacturing-Green Technology,1(3), 261–279.

Sharma, A., Mondal, S., Mondal, A. K., Baksi, S., Patel, R. K., et al. (2017). 3D printing: It’s microfluidic functions and environmental impacts. International Journal of Precision Engineering and Manufacturing-Green Technology,4(3), 323–334.

Khan, S., Lorenzelli, L., & Dahiya, R. (2014). Technologies for printing sensors and electronics over large flexible substrates: a review. IEEE Sensors Journal,15(6), 3164–3185.

Hon, K., Li, L., & Hutchings, I. (2008). Direct writing technology—Advances and developments. CIRP Annals,57(2), 601–620.

Kang, M., & Kang, K.-T. (2018). Flexible 2-layer paper printed circuit board fabricated by inkjet printing for 3-D origami electronics. International Journal of Precision Engineering and Manufacturing-Green Technology,5(3), 421–426.

Sung, K.-H., Park, J., & Kang, H. (2018). Multi-layer inkjet printing of Ag nanoparticle inks and its sintering with a near-infrared system. International Journal of Precision Engineering and Manufacturing,19(2), 303–307.

Jang, S. H., Oh, S. T., Lee, I. H., Kim, H.-C., & Cho, H. Y. (2015). 3-Dimensional circuit device fabrication process using stereolithography and direct writing. International Journal of Precision Engineering and Manufacturing,16(7), 1361–1367.

Braga, D., Erickson, N. C., Renn, M. J., Holmes, R. J., & Frisbie, C. D. (2012). High-transconductance organic thin-film electrochemical transistors for driving low-voltage red–green–blue active matrix organic light-emitting devices. Advanced Functional Materials,22(8), 1623–1631.

Hong, K., Kim, S. H., Mahajan, A., & Frisbie, C. D. (2014). Aerosol jet printed p-and n-type electrolyte-gated transistors with a variety of electrode materials: exploring practical routes to printed electronics. ACS Applied Materials and Interfaces,6(21), 18704–18711.

Mauthner, G., Landfester, K., Köck, A., Brückl, H., Kast, M., et al. (2008). Inkjet printed surface cell light-emitting devices from a water-based polymer dispersion. Organic Electronics,9(2), 164–170.

Shimoda, T., Morii, K., Seki, S., & Kiguchi, H. (2003). Inkjet printing of light-emitting polymer displays. MRS Bulletin,28(11), 821–827.

Tait, J. G., Witkowska, E., Hirade, M., Ke, T.-H., Malinowski, P. E., et al. (2015). Uniform Aerosol Jet printed polymer lines with 30 μm width for 140 ppi resolution RGB organic light emitting diodes. Organic Electronics,22, 40–43.

Crowley, K., O’Malley, E., Morrin, A., Smyth, M. R., & Killard, A. J. (2008). An aqueous ammonia sensor based on an inkjet-printed polyaniline nanoparticle-modified electrode. Analyst,133(3), 391–399.

Jang, J., Ha, J., & Cho, J. (2007). Fabrication of water-dispersible polyaniline-poly (4-styrenesulfonate) nanoparticles for inkjet-printed chemical-sensor applications. Advanced Materials,19(13), 1772–1775.

Böberl, M., Kovalenko, M. V., Gamerith, S., List, E. J., & Heiss, W. (2007). Inkjet-printed nanocrystal photodetectors operating up to 3 μm wavelengths. Advanced Materials,19(21), 3574–3578.

Zhao, D., Liu, T., Zhang, M., Liang, R., & Wang, B. (2012). Fabrication and characterization of aerosol-jet printed strain sensors for multifunctional composite structures. Smart Materials and Structures,21(11), 115008.

Hoth, C. N., Choulis, S. A., Schilinsky, P., & Brabec, C. J. (2007). High photovoltaic performance of inkjet printed polymer: fullerene blends. Advanced Materials,19(22), 3973–3978.

Contreras, M. A., Ramanathan, K., AbuShama, J., Hasoon, F., Young, D. L., et al. (2005). ACCELERATED PUBLICATION: Diode characteristics in state-of-the-art ZnO/CdS/Cu (In1 − xGax) Se2 solar cells. Progress in Photovoltaics: Research and Applications,13(3), 209–216.

Kopola, P., Zimmermann, B., Filipovic, A., Schleiermacher, H.-F., Greulich, J., et al. (2012). Aerosol jet printed grid for ITO-free inverted organic solar cells. Solar Energy Materials and Solar Cells,107, 252–258.

Ou, C., Sangle, A. L., Datta, A., Jing, Q., Busolo, T., et al. (2018). Fully printed organic-inorganic nanocomposites for flexible thermoelectric applications. ACS Applied Materials & Interfaces,10(23), 19580–19587.

Lee, J., Kim, H.-C., Choi, J.-W., & Lee, I. H. (2017). A review on 3D printed smart devices for 4D printing. International Journal of Precision Engineering and Manufacturing-Green Technology,4(3), 373–383.

Kwon, J., Park, H. W., Park, Y.-B., & Kim, N. (2017). Potentials of additive manufacturing with smart materials for chemical biomarkers in wearable applications. International Journal of Precision Engineering and Manufacturing-Green Technology,4(3), 335–347.

Kim, M.-S., Chu, W.-S., Kim, Y.-M., Avila, A. P. G., & Ahn, S.-H. (2009). Direct metal printing of 3D electrical circuit using rapid prototyping. International journal of Precision Engineering and Manufacturing,10(5), 147–150.

Ahn, D.-G. (2016). Direct metal additive manufacturing processes and their sustainable applications for green technology: A review. International Journal of Precision Engineering and Manufacturing-Green Technology,3(4), 381–395.

Wang, K., Chang, Y.-H., Zhang, C., & Wang, B. (2013). Evaluation of quality of printed strain sensors for composite structural health monitoring applications. In SAMPE fall technical conference, USA.

Mahajan, A., Frisbie, C. D., & Francis, L. F. (2013). Optimization of aerosol jet printing for high-resolution, high-aspect ratio silver lines. ACS Applied Materials and Interfaces,5(11), 4856–4864.

Kim, C., Nogi, M., & Suganuma, K. (2012). Electrical conductivity enhancement in inkjet-printed narrow lines through gradual heating. Journal of Micromechanics and Microengineering,22(3), 035016.

Doggart, J., Wu, Y., & Zhu, S. (2009). Inkjet printing narrow electrodes with < 50 μm line width and channel length for organic thin-film transistors. Applied Physics Letters,94(16), 163503.

Salary, R. R., Lombardi, J. P., Tootooni, M. S., Donovan, R., Rao, P. K., et al. (2017). Computational fluid dynamics modeling and online monitoring of aerosol jet printing process. Journal of Manufacturing Science and Engineering,139(2), 021015.

Verheecke, W., Van Dyck, M., Vogeler, F., Voet, A., & Valkenaers, H. (2012). Optimizing aerosol jet printing of silver interconnects on polyimide film for embedded electronics applications. In Eighth international DAAAM baltic conference industrial engineering, Estonia.

Oh, Y., Kim, J., Yoon, Y. J., Kim, H., Yoon, H. G., et al. (2011). Inkjet printing of Al2O3 dots, lines, and films: From uniform dots to uniform films. Current Applied Physics,11(3), S359–S363.

Soltman, D., & Subramanian, V. (2008). Inkjet-printed line morphologies and temperature control of the coffee ring effect. Langmuir,24(5), 2224–2231.

Seifert, T., Sowade, E., Roscher, F., Wiemer, M., Gessner, T., et al. (2015). Additive manufacturing technologies compared: morphology of deposits of silver ink using inkjet and aerosol jet printing. Industrial and Engineering Chemistry Research,54(2), 769–779.

Smith, M., Choi, Y. S., Boughey, C., & Kar-Narayan, S. (2017). Controlling and assessing the quality of aerosol jet printed features for large area and flexible electronics. Flexible and Printed Electronics,2(1), 015004.

Wu, D., & Xu, C. (2018). Predictive modeling of droplet formation processes in inkjet-based bioprinting. Journal of Manufacturing Science and Engineering,140(10), 101007.

Rahman, K., Khan, A., Nam, N. M., Choi, K. H., & Kim, D.-S. (2011). Study of drop-on-demand printing through multi-step pulse voltage. International Journal of Precision Engineering and Manufacturing,12(4), 663–669.

Lim, T., Yang, J., Lee, S., Chung, J., & Hong, D. (2012). Deposit pattern of inkjet printed pico-liter droplet. International Journal of Precision Engineering and Manufacturing,13(6), 827–833.

Yang, Y. J., Kim, H. C., Sajid, M., Kim, S. W., Aziz, S., et al. (2018). Drop-on-demand electrohydrodynamic printing of high resolution conductive micro patterns for MEMS repairing. International Journal of Precision Engineering and Manufacturing,19(6), 811–819.

Tan, H., Tran, T., & Chua, C. (2016). A review of printed passive electronic components through fully additive manufacturing methods. Virtual and Physical Prototyping,11(4), 271–288.

Cruz, S. M. F., Rocha, L. A., & Viana, J. C. (2018). Printing technologies on flexible substrates for printed electronics, in flexible electronics. London: IntechOpen.

Nir, M. M., Zamir, D., Haymov, I., Ben-Asher, L., Cohen, O., et al. (2010). Electrically conductive inks for inkjet printing. the chemistry of inkjet inks (pp. 225–254). Singapore: World Scientific.

King, B. H., O’Reilly, M. J., & Barnes, S.M. (2009). Characterizing aerosol Jet® multi-nozzle process parameters for non-contact front side metallization of silicon solar cells. In 34th IEEE photovoltaic specialists conference, USA.

Cai, F., Pavlidis, S., Papapolymerou, J., Chang,Y. H., Wang, K. et al. (2014). Aerosol jet printing for 3-D multilayer passive microwave circuitry. In 44th European microwave conference, Italy.

Goth, C., Putzo, S., & Franke, J. (2011). Aerosol Jet printing on rapid prototyping materials for fine pitch electronic applications. In 61st electronic components and technology conference, USA.

Paulsen, J. A., Renn, M., Christenson, K., & Plourde, R. (2012). Printing conformal electronics on 3D structures with aerosol jet technology. In 2012 future of instrumentation international workshop proceedings, USA.

Sridhar, A., Blaudeck, T., & Baumann, R. R. (2011). Inkjet printing as a key enabling technology for printed electronics. Material Matters,6(1), 12–15.

Fukuda, K., Sekine, T., Kumaki, D., & Tokito, S. (2013). Profile control of inkjet printed silver electrodes and their application to organic transistors. ACS Applied Materials and Interfaces,5(9), 3916–3920.

Ristenpart, W., Kim, P., Domingues, C., Wan, J., & Stone, H. (2007). Influence of substrate conductivity on circulation reversal in evaporating drops. Physical Review Letters,99(23), 234502.

Derby, B. (2010). Inkjet printing of functional and structural materials: fluid property requirements, feature stability, and resolution. Annual Review of Materials Research,40, 395–414.

Jang, D., Kim, D., & Moon, J. (2009). Influence of fluid physical properties on ink-jet printability. Langmuir,25(5), 2629–2635.

Son, Y., Kim, C., Yang, D. H., & Ahn, D. J. (2008). Spreading of an inkjet droplet on a solid surface with a controlled contact angle at low Weber and Reynolds numbers. Langmuir,24(6), 2900–2907.

Perelaer, J., Smith, P. J., Wijnen, M. M., van den Bosch, E., Eckardt, R., et al. (2009). Droplet tailoring using evaporative inkjet printing. Macromolecular Chemistry and Physics,210(5), 387–393.

Liu, Y.-F., Tsai, M.-H., Pai, Y.-F., & Hwang, W.-S. (2013). Control of droplet formation by operating waveform for inks with various viscosities in piezoelectric inkjet printing. Applied Physics A,111(2), 509–516.

Du, Z., Lin, Y., Xing, R., Cao, X., Yu, X., et al. (2018). Controlling the polymer ink’s rheological properties and viscoelasticity to suppress satellite droplets. Polymer,138, 75–82.

Kang, B. J., & Oh, J. H. (2010). Geometrical characterization of inkjet-printed conductive lines of nanosilver suspensions on a polymer substrate. Thin Solid Films,518(10), 2890–2896.

Chouiki, M., & Schoeftner, R. (2011). Inkjet printing of inorganic sol–gel ink and control of the geometrical characteristics. Journal of Sol-Gel Science and Technology,58(1), 91–95.

Wang, C., Hopkins, S. C., Tomov, R. I., Kumar, R. V., & Glowacki, B. A. (2012). Optimisation of CGO suspensions for inkjet-printed SOFC electrolytes. Journal of the European Ceramic Society,32(10), 2317–2324.

Sun, J., Bao, B., He, M., Zhou, H., & Song, Y. (2015). Recent advances in controlling the depositing morphologies of inkjet droplets. ACS Applied Materials and Interfaces,7(51), 28086–28099.

Kajiya, T., Kobayashi, W., Okuzono, T., & Doi, M. (2009). Controlling the drying and film formation processes of polymer solution droplets with addition of small amount of surfactants. The Journal of Physical Chemistry B,113(47), 15460–15466.

Yang, L., Kapur, N., Wang, Y., Fiesser, F., Bierbrauer, F., et al. (2018). Drop-on-demand satellite-free drop formation for precision fluid delivery. Chemical Engineering Science,186, 102–115.

Shin, P., Sung, J., & Lee, M. H. (2011). Control of droplet formation for low viscosity fluid by double waveforms applied to a piezoelectric inkjet nozzle. Microelectronics Reliability,51(4), 797–804.

Gan, H., Shan, X., Eriksson, T., Lok, B., & Lam, Y. (2009). Reduction of droplet volume by controlling actuating waveforms in inkjet printing for micro-pattern formation. Journal of Micromechanics and Microengineering,19(5), 055010.

Gao, Q., He, Y., Fu, J.-Z., Qiu, J.-J., & Jin, Y.-A. (2016). Fabrication of shape controllable alginate microparticles based on drop-on-demand jetting. Journal of Sol-Gel Science and Technology,77(3), 610–619.

Van Osch, T. H., Perelaer, J., de Laat, A. W., & Schubert, U. S. (2008). Inkjet printing of narrow conductive tracks on untreated polymeric substrates. Advanced Materials,20(2), 343–345.

Park, Y.-W., Oh, O.-K., & Noh, M. D. (2015). Ejection feasibility of high viscosity fluid with magnetostrictive inkjet printhead. International Journal of Precision Engineering and Manufacturing,16(7), 1369–1374.

Fromm, J. (1984). Numerical calculation of the fluid dynamics of drop-on-demand jets. IBM Journal of Research and Development,28(3), 322–333.

Reis, N., & Derby, B. (2000). Ink jet deposition of ceramic suspensions: Modeling and experiments of droplet formation. MRS Online Proceedings Library Archive,625, 117–122.

Szczech, J. B., Megaridis, C. M., Gamota, D. R., & Zhang, J. (2002). Fine-line conductor manufacturing using drop-on demand PZT printing technology. IEEE Transactions on Electronics Packaging Manufacturing,25(1), 26–33.

Wu, H.-C., Hwang, W.-S., & Lin, H.-J. (2004). Development of a three-dimensional simulation system for micro-inkjet and its experimental verification. Materials Science and Engineering A,373(1–2), 268–278.

De Gans, B. J., Duineveld, P. C., & Schubert, U. S. (2004). Inkjet printing of polymers: state of the art and future developments. Advanced Materials,16(3), 203–213.

Dong, H., Carr, W. W., & Morris, J. F. (2006). An experimental study of drop-on-demand drop formation. Physics of Fluids,18(7), 072102.

Seerden, K. A., Reis, N., Evans, J. R., Grant, P. S., Halloran, J. W., et al. (2001). Ink-jet printing of wax-based alumina suspensions. Journal of the American Ceramic Society,84(11), 2514–2520.

Jo, B. W., Lee, A., Ahn, K. H., & Lee, S. J. (2009). Evaluation of jet performance in drop-on-demand (DOD) inkjet printing. Korean Journal of Chemical Engineering,26(2), 339–348.

Wilson, P., Lekakou, C., & Watts, J. (2014). System design and process optimization for the inkjet printing of PEDOT: Poly (styrenesulfonate). Journal of Micro and Nano-Manufacturing,2(1), 011004.

Wu, J.-T., Hsu, S. L.-C., Tsai, M.-H., & Hwang, W.-S. (2010). Direct inkjet printing of silver nitrate/poly (N-vinyl-2-pyrrolidone) inks to fabricate silver conductive lines. The Journal of Physical Chemistry C,114(10), 4659–4662.

Chen, F., Zhang, Y., Nakagawa, Y., Zeng, H., Luo, C., et al. (2013). A piezoelectric drop-on-demand generator for accurate samples in capillary electrophoresis. Talanta,107, 111–117.

Herran, C. L., & Huang, Y. (2012). Alginate microsphere fabrication using bipolar wave-based drop-on-demand jetting. Journal of manufacturing processes,14(2), 98–106.

Davis, S. H. (1980). Moving contact lines and rivulet instabilities. Part 1. The static rivulet. Journal of Fluid Mechanics,98(2), 225–242.

Schiaffino, S., & Sonin, A. A. (1997). Formation and stability of liquid and molten beads on a solid surface. Journal of fluid mechanics,343, 95–110.

Duineveld, P. C. (2003). The stability of ink-jet printed lines of liquid with zero receding contact angle on a homogeneous substrate. Journal of Fluid Mechanics,477, 175–200.

Stringer, J., & Derby, B. (2009). Limits to feature size and resolution in ink jet printing. Journal of the European Ceramic Society,29(5), 913–918.

Kuang, M., Wang, L., & Song, Y. (2014). Controllable printing droplets for high-resolution patterns. Advanced Materials,26(40), 6950–6958.

Smith, P., Shin, D.-Y., Stringer, J., Derby, B., & Reis, N. (2006). Direct ink-jet printing and low temperature conversion of conductive silver patterns. Journal of Materials Science,41(13), 4153–4158.

Wu, J.-T., Hsu, S. L.-C., Tsai, M.-H., & Hwang, W.-S. (2011). Inkjet printing of low-temperature cured silver patterns by using AgNO3/1-dimethylamino-2-propanol inks on polymer substrates. The Journal of Physical Chemistry C,115(22), 10940–10945.

Salary, R. R., Lombardi, J. P., Rao, P. K., & Poliks, M. D. (2017). Online monitoring of functional electrical properties in aerosol jet printing additive manufacturing process using shape-from-shading image analysis. Journal of Manufacturing Science and Engineering,139(10), 101010.

Sun, H., Wang, K., Li, Y., Zhang, C., & Jin, R. (2017). Quality modeling of printed electronics in aerosol jet printing based on microscopic images. Journal of Manufacturing Science and Engineering,139(7), 071012.

Schulz, D., Hoey, J., Thompson, D., Swenson, O., Han, S., et al. (2010). Collimated aerosol beam deposition: Sub-5-$\mu $ m resolution of printed actives and passives. IEEE Transactions on Advanced Packaging,33(2), 421–427.

Akhatov, I. S., Hoey, J. M., Thompson, D., Lutfurakhmanov, A., Mahmud, Z. et al. (2009). Aerosol flow through a micro-capillary. In ASME second international conference on micro/nanoscale heat and mass transfer, China.

Hoey, J., Lutfurakhmanov, A., Robinson, M., Swenson, O., & Schulz, D. (2012). Advances in aerosol direct-write technology for fine line applications. In ASME international mechanical engineering congress and exposition, USA.

Feng, J. Q. (2017). A computational study of particle deposition patterns from a circular laminar jet. Journal of Applied Fluid Mechanics,10(4), 1001–1012.

Huang, B.-C., Chan, H.-J., Hong, J.-W., & Lo, C.-Y. (2016). Methodology for evaluating pattern transfer completeness in inkjet printing with irregular edges. Journal of Micromechanics and Microengineering,26(6), 065009.

Anyfantakis, M., Geng, Z., Morel, M., Rudiuk, S., & Baigl, D. (2015). Modulation of the coffee-ring effect in particle/surfactant mixtures: the importance of particle–interface interactions. Langmuir,31(14), 4113–4120.

Anyfantakis, M., & Baigl, D. (2014). Dynamic photocontrol of the coffee-ring effect with optically tunable particle stickiness. Angewandte Chemie,126(51), 14301–14305.

Zhang, Y., Yang, S., Chen, L., & Evans, J. (2008). Shape changes during the drying of droplets of suspensions. Langmuir,24(8), 3752–3758.

Zhang, Y., & Evans, J. R. (2013). Morphologies developed by the drying of droplets containing dispersed and aggregated layered double hydroxide platelets. Journal of colloid and interface science,395, 11–17.

Wang, L., Wang, J., Huang, Y., Liu, M., Kuang, M., et al. (2012). Inkjet printed colloidal photonic crystal microdot with fast response induced by hydrophobic transition of poly (N-isopropyl acrylamide). Journal of Materials Chemistry,22(40), 21405–21411.

Majumder, M., Rendall, C. S., Eukel, J. A., Wang, J. Y., Behabtu, N., et al. (2012). Overcoming the “coffee-stain” effect by compositional Marangoni-flow-assisted drop-drying. The Journal of Physical Chemistry B,116(22), 6536–6542.

Bao, B., Li, M., Li, Y., Jiang, J., Gu, Z., et al. (2015). Patterning fluorescent quantum dot nanocomposites by reactive inkjet printing. Small (Weinheim an der Bergstrasse, Germany),11(14), 1649–1654.

Lessing, J., Glavan, A. C., Walker, S. B., Keplinger, C., Lewis, J. A., et al. (2014). Inkjet Printing of conductive inks with high lateral resolution on omniphobic “Rf paper” for paper-based electronics and MEMS. Advanced Materials,26(27), 4677–4682.

Li, Y., Mohan, K., Sun, H., & Jin, R. (2017). Ensemble modeling of in situ features for printed electronics manufacturing with in situ process control potential. IEEE Robotics and Automation Letters,2(4), 1864–1870.

Wang, T., Kwok, T.-H., Zhou, C., & Vader, S. (2018). In-situ droplet inspection and closed-loop control system using machine learning for liquid metal jet printing. Journal of manufacturing systems,47, 83–92.

Li, Y., Sun, H., Deng, X., Zhang, C., Wang, H.-P., et al. (2019). Manufacturing quality prediction using smooth spatial variable selection estimator with applications in Aerosol Jet® printed electronics manufacturing. IISE Transactions, Accepted, pp. 1–17

Wang, T., Zhou, C., & Xu, W. (2019). Online droplet monitoring in inkjet 3D printing using catadioptric stereo system. IISE Transactions,51(2), 153–167.

Wang, A., Wang, T., Zhou, C., & Xu, W. (2017). LuBan: Low-cost and in situ droplet micro-sensing for inkjet 3D printing quality assurance. In Proceedings of the 15th ACM conference on embedded network sensor systems, USA.

Lies, B. T., Cai, Y., Spahr, E., Lin, K., & Qin, H. (2018). Machine vision assisted micro-filament detection for real-time monitoring of electrohydrodynamic inkjet printing. Procedia Manufacturing,26, 29–39.

Kwon, K.-S. (2009). Speed measurement of ink droplet by using edge detection techniques. Measurement,42(1), 44–50.

Nguyen, T. K., Nguyen, V. D., Seong, B., Hoang, N., Park, J., et al. (2014). Control and improvement of jet stability by monitoring liquid meniscus in electrospray and electrohydrodynamic jet. Journal of Aerosol Science,71, 29–39.

Lombardi, J. P., Salary, R.R., Weerawarne, D.L., Rao, P.K. & Poliks, M.D. (2018). In-situ image-based monitoring and closed-loop control of aerosol jet printing. In ASME 13th international manufacturing science and engineering conference, USA.

Park, J.-K., Kwon, B.-K., Park, J.-H., & Kang, D.-J. (2016). Machine learning-based imaging system for surface defect inspection. International Journal of Precision Engineering and Manufacturing-Green Technology,3(3), 303–310.

Seong, J., Kim, S., Park, J., Lee, D., & Shin, K.-H. (2015). Online noncontact thickness measurement of printed conductive silver patterns in roll-to-roll gravure printing. International Journal of Precision Engineering and Manufacturing,16(11), 2265–2270.

Kim, J. S., Lee, C. S., Kim, S.-M., & Lee, S. W. (2018). Development of data-driven in-situ monitoring and diagnosis system of fused deposition modeling (FDM) process based on support vector machine algorithm. International Journal of Precision Engineering and Manufacturing-Green Technology,5(4), 479–486.

Chua, Z. Y., Ahn, I. H., & Moon, S. K. (2017). Process monitoring and inspection systems in metal additive manufacturing: Status and applications. International Journal of Precision Engineering and Manufacturing-Green Technology,4(2), 235–245.

Kwon, K.-S., Go, J.-K., Kim, J.-W. & Oh, D. (2010). In situ measurement of instantaneous jetting speed curve. In NIP & digital fabrication conference, USA.

Rasmussen, C. E. (1999). Evaluation of Gaussian processes and other methods for non-linear regression. Toronto: University of Toronto.

Yuan, J., Wang, K., Yu, T., & Fang, M. (2008). Reliable multi-objective optimization of high-speed WEDM process based on Gaussian process regression. International Journal of Machine Tools and Manufacture,48(1), 47–60.

Pan, S. J., & Yang, Q. (2010). A survey on transfer learning. IEEE Transactions on Knowledge and Data Engineering,22(10), 1345–1359.

Luo, L., Yao, Y., & Gao, F. (2015). Bayesian improved model migration methodology for fast process modeling by incorporating prior information. Chemical Engineering Science,134, 23–35.

Hou, Z.-S., & Wang, Z. (2013). From model-based control to data-driven control: Survey, classification and perspective. Information Sciences,235, 3–35.

Formentin, S., Van Heusden, K., & Karimi, A. (2014). A comparison of model-based and data-driven controller tuning. International Journal of Adaptive Control and Signal Processing,28(10), 882–897.

Acknowledgements

This research work was conducted in the SMRT-NTU Smart Urban Rail Corporate Laboratory with funding support from the National Research Foundation (NRF), SMRT and Nanyang Technological University; under the Corp Lab@University Scheme.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

This paper is an invited paper.

Rights and permissions

About this article

Cite this article

Zhang, H., Moon, S.K. & Ngo, T.H. 3D Printed Electronics of Non-contact Ink Writing Techniques: Status and Promise. Int. J. of Precis. Eng. and Manuf.-Green Tech. 7, 511–524 (2020). https://doi.org/10.1007/s40684-019-00139-9

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40684-019-00139-9