Abstract

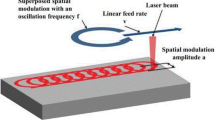

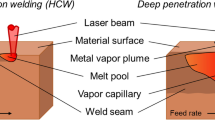

Radiation propagation and temperature development are simulated for laser-transmission welding of polycarbonate and polybutylene terephthalate parts. The simulations are carried out for a Gaussian- and an M-shape laser beam. For polycarbonate the shape of the laser beam is preserved, while for polybutylene terephthalate it is altered due to scattering processes. The resulting intensity and integrated intensity distribution in the joining zone are calculated for both polymers. They give rise to different temperature fields. The dimensions of the model seam are approximated by the dimensions of the melt isotherm. For polycarbonate the seam generated by a Gaussian beam has a non-homogeneous thickness and a width that is smaller than the beam diameter. For an M-shape beam it has a homogeneous thickness and its width scales with the width of the integrated intensity. For polybutylene terephthalate volumetric scattering destroys the original beam shape in the joining zone. The distributions of the integrated intensities and the dimensions of the seam are similar for both types of beams.

Similar content being viewed by others

References

Grewell, D.A.: Application with infrared welding of thermoplastics. ANTEC 1999, 1411–1415 (1999)

BASF Aktiengesellschaft, Transmission Laser-Welding of Thermoplastics, http://www2.basf.us/webplasticsportal/cre?gui=1&dtitle=searchResult&dtext=1&objecttype=ktn_technical_documents&ktn_t_doctype=Technical_Papers. (2001)

Bachmann, F.G., Russek.: Laser welding of polymers using high power diode lasers. Proc. SPIE 505–518 (2002)

BASF Corporation: Innovations in laser welding of thermoplastics. http://www2.basf.us/webplasticsportal/cre?gui=1&dtitle=searchResult&dtext=1&objecttype=ktn_technical_documents&ktn_t_doctype=Technical_Papers (2002)

Russek, U., Gillner, A., Poggel, M.: Joining with light. Kunststoffe Int. 50–54 (2006)

Haberstroh, E., Hoffmann, W.-M., Poprawe, R., Fahri, S.: Applications of laser transmission processes for the joining. Microsyst. Technol. 632–639 (2006)

Klotzbuecher, T., Letschert, M., Braune, T., Drese, K.-S., Doll, T.: Diode laser welding for packaging of transparent micro-structured polymer chips. In: Bachmann, F.G., Hoving, W., Lu, Y., Washio, K. (Eds.), Lasers and applications in science and engineering. 610704–610704-14., SPIE (2006)

Prabhakaran, P., Kontopoulou, M., Zak, G., Bates, G.J., Baylis, B.K.: Contour laser - laser-transmission welding of glass reinforced nylon 6. J. Thermoplastic Compos. Mater. 427–439 (2006)

Geiger, M., Frick, T., Schmidt, M.: Optical properties of plastics and their role for the modelling of the laser transmission welding process. Prod. Eng. Res. Devel. 49–55 (2009)

Ghorbel, E., Casalino, G., Abed, S.: Laser diode transmission welding of polypropylene: geometrical and microstructure characterisation of weld. Mater. Des. 2745–2750 (2009)

Chen, M.-L., Bates, P.J., Zak, G.: Effect of carbon black on light transmission in laser welding of thermoplastics. J. Mater. Process. Technol. 43–47 (2011)

Industrial Laser Solution for Manufacturing.: Fiber laser welding of white goods. http://www.industrial-lasers.com/articles/2013/04/fiber-laser-welding-of-white-goods--.html, accessed 17 August 2015. (2013)

LPKF, Kunststoffschweißen für Automotive, Medizintechnik und die Consumer Industrie, 2015, http://www.lpkf-laserwelding.de. (2015)

Taft, E.A., Philipp, H.R.: Optical properties of graphite*. Phys. Rev. 197–202 (1964)

Djurisic, A.B., Li, H.E.: Optical properties of graphite. J. Appl. Phys. 7404–7410 (1999)

Boglea, A., Olowinsky, A., Gillner, A.: Fibre laser welding for packaging of disposable polymeric microfluidic-biochips. Appl. Surf. Sci. 254, 1174–1178 (2007)

Aden, M., Otto, G., Duwe, C.: Irradiation strategy for laser transmission welding of thermoplastics using high brilliance laser source. Int. Polym. Process. 28, 300–305 (2013)

Aden, M., Liviany, F., Olowinsky, A.: Joint strength for laser transmission welding of thermoplastics: a simulation approach. Int. Polymer Process. 79–83 (2013)

Rauschenberger, J., Vogler, D., Raab, C., Gubler, U.: Diffractive beam shaping for enhanced laser polymer welding. In Klotzbach, U., Washio, K., Arnold, C.B. (Eds.), SPIE LASE, SPIE 935110. C.B. (2015)

LIMO Lissotschenko Mikrooptik GmbH, Laser welding thermoplastics with customized beam intensity. http://www.industrial-lasers.com/articles/print/volume-26/issue-4/departments/enter-the-world-of-green-cars.html, accessed 17 August 2015. (2011)

Kagan, V.A., Bray, R.G., Kuhn, W.P.: laser transmission welding of semi-crystalline thermoplastics-part I: optical characterization of nylon based plastics. J. Reinf. Plast. Comp. 21, 1101–1122 (2002)

Aden, M.,Roesner, A., Olowinsky A.: Optical characterization of Polycarbonate: influence of additives on optical properties. J. Polymer Sci.: Part B 451–455 (2010)

Aden, M.,Mamuschkin, V.,Olowinsky, A.,Glaser, S.: Influence of titanium dioxide pigments on the optical properties of polycarbonate and polypropylene for diode laser wavelengths. J. Appl. Polym. Sci. 131 (2014)

Hänsch, D.: Die optischen Eigenschaften von Polymeren und ihre Bedeutung für das Durchstrahlschweißen mit Diodenlaser: Diss. RWTH Aachen, Shaker (2001)

Caudill, S.E.,Grubbs, W.T.: Interferometric measurements of refractive index dispersion in polymers over the visible and near-infrared spectral range. J. Appl. Polym. Sci. 65–72 (2006)

Ishimaru, A.: Wave propagation and scattering in random media, an IEEE/OUP series on electromagnetic wave theory. IEEE Press; Oxford University Press, New York (1997)

Gangadhara, S.: What scattering models are available in zemax?. http://www.zemax.com/support/resource-center/knowledgebase/what-scattering-models-are-available-in-zemax, accessed 11.2015. (2010)

Potente, H., Korte, J., Becker, F.: Laser transmission welding of thermoplastics: analysis of the heating phase. j. Reinf. Plast. Comp. 914–920 (1999)

Van de Ven, J D, Erdman, A.G.: Laser transmission welding of thermoplastics—part I: temperature and pressure modeling. J. Manufac. Sci. Eng. 849–858 (2007)

Mayboudi, L.S.,Birk, A.M.,Zak, G.,Bates, P.J.: Laser transmission welding of a lap-joint: thermal imaging observations and three–dimensional finite element modeling. J. Heat Transfer 1177–1186 (2007)

Ilie, M.,Kneip, J.-C., Matteı, S., Nichici, A.: Through-transmission laser welding of polymers – temperature field modeling and infrared investigation. Infrared Phys. Technol. 73–79 (2007)

Geiger, M., Frick, T., Schmidt, M.: Optical properties of plastics and their role for the modelling of the laser transmission welding process. Prod. Eng. Res. Dev. 49–55 (2009)

Ilya Mingareev, I., Weirauch, F., Olowinsky, A., Shah, L., Kadwani, P., Richardson, M.: Welding of polymers using a 2 mm thulium fiber laser. Optics Laser Technol. 2095–2099 (2012)

Acherjee, B., Kuar, A.S., Mitra, S., Misra, D.: Modeling and analysis of simultaneous laser transmission welding of polycarbonates using an FEM and RSM combined approach. Optios Laser Technol. 44, 995–1006 (2012)

Russek, U.A.: Prozesstechnische Aspekte des Laserdurchstrahlschweissens von Thermoplasten, Berichte aus der Lasertechnik. Shaker, Aachen (2006)

Mitsubishi Engineering Plastics, About Novaduran. www.google.de/search?q=limo&ie=utf-8&oe=utf-8&gws_rd=cr&ei=KCcmVc-EINHhaL77gYgD#q=www.m-ep.co.jpg%2Fen%2Fpdf%2Fproduct%2Fnovaduran%2Fphysicality.pdf. (2015)

Aden, M.,Mamuschkin, V.,Olowinsky, A.: Influence of carbon black and indium tin oxide absorber particles on laser transmission welding. Optics Laser Technol. 87–91 (2015)

Frei, W.: Modeling laser-material interactions in COMSOL multiphysics. www.comsol.de/blogs/modeling-laser-material-interactions-in-comsol-multiphysics/. (2015)

Acknowledgments

The author would like to thank Mrs. Frauke Legewie from LIMO Lissotschenko Mikrooptik GmbH, who provides the M-shape data.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Aden, M. Influence of the Laser-Beam Distribution on the Seam Dimensions for Laser-Transmission Welding: A Simulative Approach. Lasers Manuf. Mater. Process. 3, 100–110 (2016). https://doi.org/10.1007/s40516-016-0023-x

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40516-016-0023-x