Abstract

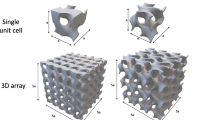

One promising way to enhance the heat transfer coefficient (HTC) and the critical heat flux (CHF) is modifying the heating surface morphology by using machining techniques, coating, and chemical processes. Microstructured surfaces, i.e., surfaces with the presence of micropillars on the surface, provide small perturbations in the liquid, affecting the vapor bubbles dynamic. These structures increase the heating surface area and change the fluid flow. Microfins can have different shapes and sizes and can be arranged in different patterns to improve heat transfer. This study aims to evaluate experimentally the thermal performance of different microfin surfaces by using HFE-7100 as working fluid. Square micro-pillar arrays were etched on a plain copper surface through the micro-milling process. Square microfins of different length scales (i.e., height and side length) were uniformly spaced on the plain copper surface. The inter-fin space had the same value, 250 μm, for all surfaces in order to control the effective roughness, Reff, defined as the ratio of the area in contact with the liquid to the projected area. Microfin surfaces intensify the HTC as compared to plain surfaces and the number of fins is the main factor for the HTC enhancement; if the number of microfins is constant, the larger the effective roughness, the higher the heat transfer performance. Additionally, the capillary-wicking ability increases and it also improves the HTC and the dryout heat flux due to the prevention of hotspots in the microfin surface. Thus, the surface thermal behavior is a function of the surface morphology and its surface capillary wicking.

Similar content being viewed by others

Abbreviations

- b :

-

Exponent related to roughness effect (–)

- c p :

-

Specific heat capacity (J/kg K)

- C sf :

-

Surface-fluid coefficient (–)

- D :

-

Fin length (µm)

- D d :

-

Bubble departure diameter (m)

- f w :

-

Heat surface material parameter (–)

- h :

-

Heat transfer coefficient (W/m2 K)

- H :

-

Fin height (µm)

- k :

-

Thermal conductivity (W/m K)

- k Cu :

-

Copper thermal conductivity (W/m K)

- L :

-

Copper block distances (m)

- M :

-

Molar mass (kg/kmol)

- n :

-

Stephan’s exponent (–)

- P :

-

Pressure (Pa)

- Pr:

-

Prandtl number (–)

- p r :

-

Reduced pressure (–)

- q″ measured :

-

Heat flux measured at the copper block (W/m2)

- R a :

-

Average surface roughness (µm)

- R p :

-

Maximum peak height of surface roughness (µm)

- S :

-

Inter-fin space (µm)

- T :

-

Temperature (K)

- u i :

-

Uncertainty

- ΔT :

-

Temperature difference (K)

- θ :

-

Static contact angle (°)

- µ :

-

Dynamic viscosity (kg/m s)

- ρ :

-

Density (kg/m3)

- σ :

-

Surface tension (N/m)

- 1, 2, or 3:

-

Thermocouples position

- atm:

-

Atmospheric condition

- HTE:

-

Heat transfer enhancement ratio

- l or liq:

-

Liquid

- sat:

-

Saturated state

- vap:

-

Vapor

- s :

-

Surface

References

Demir E, Izci T, Alagoz AS, Karabacak T, Kosar A (2014) Effect of silicon nanorod length on horizontal nanostructured plates in pool boiling heat transfer with water. Int J Therm Sci 82:111–121

Bejan A (1984) Convection heat transfer. Wiley, Nova York

Liang G, Mudawar I (2019) Review of pool boiling enhancement by surface modification. Int J Heat Mass Transf 128:892–933

Cao Z, Liu B, Preger C, Wu Z, Zhang Y, Wang X, Sundén B (2018) Pool boiling heat transfer of FC-72 on pin-fin silicon surfaces with nanoparticle deposition. Int J Heat Mass Transf 126:1019–1033

Cooke D, Kandlikar SG (2012) Effect of open microchannel geometry on pool boiling enhancement. Int J Heat Mass Transf 55:1004–1013

Jaikumar A, Kandlikar SG (2016) Ultra-high pool boiling performance and effect of channel width with selectively coated open microchannels. Int J Heat Mass Transf 95:795–805

Kim BS, Lee H, Shin S, Choi G, Cho HH (2014) Interfacial wicking dynamics and its impact on critical heat flux of boiling heat transfer. Appl Phys Lett 105:191601

Kim SH, Lee GC, Kang JY, Moriyama K, Kim MH, Park HS (2015) Boiling heat transfer and critical heat flux evaluation of the pool boiling on microstructured surface. Int J Heat Mass Transf 91:1140–1147

Rainey KN, You SM (2000) Pool boiling heat transfer from plain and microporous, square pin-finned surfaces in saturated FC-72. ASME J Heat Transf 122:509–516

Nirgude VV, Sahu SK (2017) Enhancement of nucleate boiling heat transfer using structured surfaces. Chem Eng Process Process Intensif 122:222–234

Dong L, Quan X, Cheng P (2014) An experimental investigation of enhanced pool boiling heat transfer from surfaces with micro/nano-structures. Int J Heat Mass Transf 71:189–196

Sinha-Ray S, Zhang W, Sahu RP, Sinha-Ray S, Yarin AL (2017) Pool boiling of Novec 7300 and DI water on nano-textured heater covered with supersonically-blown or electrospun polymer nanofibers. Int J Heat Mass Transf 106:482–490

Zhong D, Meng J, Li Z, Guo Z (2015) Critical heat flux for downward-facing saturated pool boiling on pin fin surfaces. Int J Heat Mass Transf 87:201–211

Ahn HS, Park G, Kim JM, Kim J, Kim NH (2012) The effect of water absorption on critical heat flux enhancement during pool boiling. Exp Therm Fluid Sci 42:187–195

Rahman M, Olceroglu E, McCarthy M (2014) Role of wickability on the critical heat flux of structured superhydrophilic surfaces. Langmuir 30(37):11225–11234

Chu K-H, Enright R, Wang EN (2012) Structured surfaces for enhanced pool boiling heat transfer. Appl Phys Lett 100(24):241603

Manetti LL, Ribatski G, Souza RR, Cardoso EM (2020) Pool boiling heat transfer of HFE-7100 on metal foams. Exp Therm Fluid Sci 113:110025

Manetti LL, Mogaji TS, Beck PA, Cardoso EM (2017) Evaluation of the heat transfer enhancement during pool boiling using low concentrations of Al2O3-water based nanofluid. Exp Therm Fluid Sci 87:191–200

Teodori E, Moita AS, Moreira ALN (2014) Empirical and modeling-based correlations for pool boiling on microstructured surfaces, Interfacial Phenom. Heat Transf 2:273–292

M product brochure, 3M Novec™ engineered fluid HFE-7100 for heat transfer (2002)

Moffat RJ (1988) Describing the uncertainties in experimental results, pp 3–17

Rohsenow WM (1952) A method of correlating heat transfer data for surface boiling of liquids. Trans ASME J Heat Transf 74:969–976

Cooper MG (1984) Heat flow rates in saturated nucleate pool boiling—a wide-ranging examination using reduced properties, pp 157–239

Ribatski G, Jabardo JMS (2003) Experimental study of nucleate boiling of halocarbon refrigerants on cylindrical surfaces. Int J Heat Mass Transf 46:4439–4451

Kiyomura IS, Manetti LL, da Cunha AP, Ribatski G, Cardoso EM (2017) An analysis of the effects of nanoparticles deposition on characteristics of the heating surface and on pool boiling of water. Int J Heat Mass Transf 106:666–674

Stephan K (1992) Heat transfer in condensation and boiling. Springer, Berlin

Cao Z, Wu Z, Sundén B (2019) Heat transfer prediction and critical heat flux mechanism for pool boiling of NOVEC-649 on microporous copper surfaces. Int J Heat Mass Transf 141:818–834

Cardoso EM, Kannengieser O, Stutz B, Passos JC (2011) FC72 and FC87 nucleate boiling inside a narrow horizontal space. Exp Therm Fluid Sci 35:1038–1045

Duan Z, Ren T, Ding G (2019) Suppression effects of microfin surface on the explosive boiling of liquefied gas under rapid depressurization. J Hazard Mater 365:375–385

Yu CK, Lu DC (2007) Pool boiling heat transfer on horizontal rectangular fin array in saturated FC-72. Int J Heat Mass Transf 50(17):3624–3637

Pastuszko R (2012) Pool boiling for extended surfaces with narrow tunnels—visualization and a simplified model. Exp Therm Fluid Sci 38(1):149–164

Sarafraz M, Hormozi F (2016) Experimental investigation on the pool boiling heat transfer to aqueous multi-walled carbon nanotube nanofluids on the microfinned surfaces. Int J Therm Sci 100:255–266

Acknowledgements

The authors are grateful for the financial support from CAPES, from CNPq (458702/2014-5) and from FAPESP (2013/15431-7, 2017/13813-0 and 2019/02566-8). The authors also extend their gratitude to Prof. Alessandro Roger Rodrigues from EESC/USP for his important contribution to this work.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The author(s) declared no potential conflicts of interest with respect to the research, authorship and/or publication of this article.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

This article has been selected for a Topical Issue of this journal on Nanoparticles and Passive-Enhancement Methods in Energy.

Rights and permissions

About this article

Cite this article

Kiyomura, I.S., Nunes, J.M., de Souza, R.R. et al. Effect of microfin surfaces on boiling heat transfer using HFE-7100 as working fluid. J Braz. Soc. Mech. Sci. Eng. 42, 366 (2020). https://doi.org/10.1007/s40430-020-02439-7

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s40430-020-02439-7