Abstract

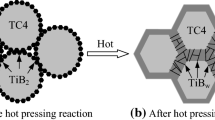

The present study focuses on the drilling processes and its parameters of titanium–titanium boride composites which are optimized using Taguchi technique. The titanium–titanium boride composites aiming 20% and 40% of titanium boride (by volume) is processed through three different powder metallurgical techniques such as, spark plasma sintering, hot isostatic pressing and vacuum sintering, respectively. It is processed through the drilled holes in the composites of 1 mm thickness using a solid carbide drill of 2 mm diameter. The effects of process parameters such as, feed rate, spindle speed and processing techniques on the drilling thrust force and surface roughness are analyzed. The results reveal that the feed rate and processing techniques are the most significant parameters influencing the thrust force and surface roughness. High thrust force and surface roughness are observed for the composites with 40% of titanium boride (by volume) processed through the spark plasma sintering technique. Further, the wear mode of drill edges, workpiece damage and chip morphology are also examined.

Similar content being viewed by others

References

Selvakumar M, Chandrasekar P, Mohanraj M, Ravisankar B, Balaraju JN (2015) Role of powder metallurgy processing and TiB reinforcement on mechanical response of Ti–TiB composites. J Mater Lett 144:58–61

Selvakumar N, Ramkumar T (2016) Effect of high temperature wear behaviour of sintered Ti–6Al–4V reinforced with nano B4C particles. Trans Indian Inst Met 69(6):1267–1276

Wang FC, Zhang Z, Luo J, Huang CC, Lee SK (2009) A novel rapid route for in situ synthesizing TiB–TiB composites. Compos Sci Technol 69:2682–2687

Selvakumar M, Chandrasekar P, Chandramohan P, Mohanraj M (2012) Characterisation of titanium–titanium boride composites processed by powder metallurgical techniques. Mater Charact 73:43–51

Ramesh B, Elayaperumal A, Satishkumar S, Kumar A (2018) Drilling of pultruded and liquid composite moulded glass/epoxy thick composites: experimental and statistical investigation. Measurement 114:109–121

Palanikumar K, Muniaraj A (2014) Experimental investigation and analysis of thrust force in drilling cast hybrid metal matrix (Al–15%SiC–4%graphite) composites. Measurement 53:240–250

Selvakumar M, Chandrasekar P, Ravisankar B, Balaraju JN, Mohanraj M (2015) Mechanical properties of titanium–titanium boride composites through nano-indentation and ultrasonic techniques: an evaluation perspective. Powder Metall Met Ceram 53(9–10):557–565

Zhang Z, Shen XB, Wen S, Luo J, Lee SK, Wang FC (2010) In situ reaction synthesis of Ti–TiB composites containing high volume fraction of TiB by spark plasma sintering process. J Alloy Compd 503:145–150

Selvakumar N, Ramkumar T (2017) Effect of particle size of B4C reinforcement on Ti–6Al–4V sintered composite prepared by mechanical milling method. Trans Indian Ceram Soc 76(1):37-37

Prasanna J, Karunamoorthy L, Venkatraman M, Prashanth S, Raj Chordia D (2014) Optimization of process parameters of small hole dry drilling in Ti–6Al–4V using Taguchi and grey relational analysis. Measurement 48:346–354

Pettersson A, Magnusson P, Lundberg P, Nygren M (2005) Titanium–titanium diboride composites as part of a gradient armour material. Int J Impact Eng 32:387–399

Chandrasekar P, Balusamy V, Ravi Chandran KS, Kumar H (2007) Laser surface hardening of titanium–titanium boride (Ti–TiB) metal matrix composites. Scr Mater 56:641–644

Sheth S, George PM (2016) Experimental investigation, prediction and optimization of cylindricity and perpendicularity during drilling of WCB material using grey relational analysis. Precis Eng 45:33–43

Ezugwu EO, Wang ZM (1997) Titanium alloys and their machinability: a review. J Mater Process Technol 68:262–274

Machado AR, Wallbank J (1990) Machining of titanium and its alloys: a review. Proc Inst Mech Eng B J Eng Manuf 204:53–60

Perçin M, Aslantas K, Çicek A (2016) Micro-drilling of Ti–6Al–4V alloy: the effects of cooling/lubricating. Precis Eng 45:450–462

Ramulu M, Branson T, Kim D (2001) A study on the drilling of composite and titanium stacks. Compos Struct 54:67–77

Zhang PF, Churi NJ, Pei ZJ, Treadwell C (2008) Mechanical drilling process for titanium alloys: a literature review. Mach Sci Technol 12:417–444

Zhu L, Wang J (2006) A study on titanium alloys deep hole drilling technique. Mater Sci Forum 532:945–948

Cantero J, Tardio L, Canteli M, Marcos JA, Miguelez M (2005) Dry drilling of alloy Ti–6Al–4V. J Mach Tool Manuf 45:1246–1255

Yang X, Liu CR (1999) Machining titanium and its alloys. Mach Sci Technol 3:107–139

Kurt M, Bagci E, Kaynak Y (2009) Application of Taguchi methods in the optimization of cutting parameters for surface finish and hole diameter accuracy in dry drilling processes. Int J Adv Manuf Technol 40(5–6):458–469

Ramesh S, Karunamoorthy L, Palanikumar K (2008) Surface roughness analysis in machining of titanium alloy. Mater Manuf Process 23(2):174–181

Ramkumar T, Narayanasamy P, Selvakumar M, Balasundar P (2018) Effect of B4C reinforcement on the dry sliding wear behaviour of Ti–6Al–4V/B4C sintered composites using response surface methodology. Arch Metall Mater 63(3):1179–1200

Tansel IN, Gulmez S, Demetgul M, Aykut S (2011) Taguchi method-GONNs integration: complete procedure covering from experimental design to complex optimization. Expert Syst Appl 38:4780–4789

Yilmaz O, Bozdana AT, Okka MA (2014) An intelligent and automated system for electrical discharge drilling of aerospace alloys: Inconel 718 and Ti–6Al–4V. Int J Adv Manuf Technol 74(9–12):1323–1336

Azad MS, Puri AB (2012) Simultaneous optimization of multiple performance characteristics in micro-EDM drilling of titanium alloy. Int J Adv Manuf Technol 61(9–12):1231–1239

Kao JY, Tsao CC, Wang SS, Hsu CY (2010) Optimization of the EDM parameters on machining Ti–6Al–4V with multiple quality characteristics. Int J Adv Manuf Technol 47(1–4):395–402

Fernández J, PérezaJ L, Cantero D, Álvarez J, Miguélez MH (2017) Influence of cutting parameters on tool wear and hole quality in composite aerospace components drilling. Compos Struct 178:157–161

Acknowledgements

The researchers would like to thank Mr. M. Thirumoorthy, ASL, Hyderabad, India for his support in executing this research.

Author information

Authors and Affiliations

Corresponding author

Additional information

Technical Editor: Márcio Bacci da Silva, Ph.D.

Rights and permissions

About this article

Cite this article

Ramkumar, T., Selvakumar, M., Mohanraj, M. et al. Experimental investigation and analysis of drilling parameters of metal matrix (Ti/TiB) composites. J Braz. Soc. Mech. Sci. Eng. 41, 8 (2019). https://doi.org/10.1007/s40430-018-1507-8

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s40430-018-1507-8