Abstract

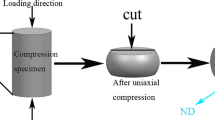

Hot compression tests of Mg–11Gd–4Y–2Zn–0.4Zr alloy (GWZK114) were conducted at a deformation temperature range of 300–500 °C and a strain rate range of 0.01–10.0 s−1. Based on systematic microstructure observation, it is confirmed that long period stacking ordered (LPSO) phase displays essential and evolving roles on the dynamic recrystallization (DRX) behavior. The results indicate that the plastic deformation is mainly coordinated by simultaneous exist of LPSO kinking of lamella 14H-LPSO phase and DRX at 350–450 °C, and DRX at 500 °C. Further, it is found that the LPSO kinking induced during 350–450 °C can delay the DRX. A phenomenological DRX model of GWZK114 alloy is established to be \(X_{\text{DRX}} = 1 - \exp [ - 0.5(\frac{{\varepsilon - \varepsilon_{\text{c}} }}{{\varepsilon^{*} }})^{0.91} ]\). Non-uniform distribution of plastic strain during compression was considered via finite element method and it ensures a good prediction of DRX fraction under a large plastic strain. Meanwhile, an enhanced DRX model, taking its formulation as \(X_{\text{DRX}} = \{ 1 - \exp [ - 0.5(\frac{{\varepsilon - \varepsilon_{c} }}{{\varepsilon^{*} }})^{0.91} ]\} (\frac{T}{226.8} - 1)^{n}\), \(n = 3.82\dot{\varepsilon }^{0.083}\), is proposed for the first time to capture the hindering effect of 14H-LPSO kinking on DRX behavior. The predicted results of this enhanced DRX model agree well with the experimental cases, where 14H-LPSO kinking is dominated or partially involved (300–450 °C). Besides, a size model of DRX grains is also established and can depict the evolution of DRX grain size for all the investigated compression conditions with accounting for temperature rising at high strain rates (5 s−1 and 10 s−1).

Similar content being viewed by others

References

T.M. Pollock, Science 328, 986–987 (2010)

J.W. Dai, X.B. Zhang, Y. Fei, Z.Z. Wang, H.M. Sui, Acta Metall. Sin. (Engl. Lett.) 31, 865–872 (2018)

K. Hagihara, A. Kinoshita, Y. Yamasaki, M. Yamasaki, Y. Kawamura, Mater. Sci. Eng. A 560, 71–79 (2013)

M. Yamasaki, Y. Kawamura, Scr. Mater. 60, 264–267 (2009)

T. Itoi, K. Takahashi, H. Moriyama, H. Moriyama, M. Hirohashi, Scr. Mater. 59, 1155–1158 (2008)

Y. Kawamura, T. Kasahara, S. Izumi, M. Yamasaki, Scr. Mater. 55, 453–456 (2006)

K. Hagihara, A. Kinoshita, Y. Sugino, M. Yamasaki, Y. Kawamura, H.Y. Yasuda, Y. Umakoshi, Acta Mater. 58, 6282–6293 (2010)

K. Hagihara, M. Honnami, R. Matsumoto, Y. Fukusumi, H. Izuno, M. Yamasaki, T. Okamoto, T. Nakano, Y. Kawamura, Mater. Trans. 56, 943–951 (2015)

X.H. Shao, Z.Q. Yang, X.L. Ma, Acta Mater. 58, 4760–4771 (2010)

E. Oñorbe, G. Garcés, P. Pérez, P. Adeva, J. Alloys Compd. 47, 1085–1093 (2012)

C. Xu, T. Nakata, X. Qiao, M. Zheng, K. Wu, S. Kamado, Sci Rep. 7, 40846 (2017)

D. Zhang, Z. Tan, Q. Huo, Z. Xiao, Z. Fang, X. Yang, Mater. Sci. Eng. A 715, 389–403 (2018)

B.J. Lv, J. Peng, Y. Peng, A.T. Tang, F.S. Pan, Mater. Sci. Eng. A 579, 209–216 (2013)

W. Yuan, S.K. Panigrahi, J.Q. Su, R.S. Mishra, Scr. Mater. 65, 994–997 (2011)

J.A. Del Valle, F. Carreño, O.A. Ruano, Acta Mater. 54, 4247–4259 (2006)

M.R. Barnett, Z. Keshavarz, A.G. Beer, D. Atwell, Acta Mater. 52, 5093–5103 (2004)

X.H. Huang, K. Suzuki, Y. Chino, M. Mabuchi, J. Alloys Compd. 632, 94–102 (2015)

T. Homma, N. Kunito, S. Kamado, Scr. Mater. 61, 644–647 (2009)

I. Schindler, P. Kawulok, E. Hadasik, D. Kuc, JMEPEG 22, 890–897 (2013)

Z. Yang, Y.C. Guo, J.P. Li, F. He, F. Xia, M.X. Liang, Mater. Sci. Eng. A 485, 487–491 (2008)

G.Z. Quan, Y. Shi, Y.X. Wang, B.S. Kang, W.T. Ku, W.J. Song, Mater. Sci. Eng. A 528, 8051–8059 (2011)

J. Liu, Z.S. Cui, L.Q. Ruan, Mater. Sci. Eng. A 529, 300–310 (2011)

E.I. Poliak, J.J. Jonas, Acta Mater. 44, 127–136 (1996)

A. Najafizadeh, J.J. Jonas, ISIJ Int. 46, 1679–1684 (2006)

B.J. Lv, J. Peng, L.L. Zhu, Y.J. Wang, Mater. Sci. Eng. A 599, 150–159 (2014)

J. Yu, Z. Zhang, Q. Wang, X. Yin, J. Cui, H. Qi, J. Alloys Compd. 704, 382–389 (2017)

G. Zhang, Z. Zhang, Y. Du, Z. Yan, X. Che, Materials 11, 2092 (2018)

Y. Du, Dissertation, North University of China, 2018 (in Chinese)

C.J. Wang, Z.G. Zhou, A. Holmqvist, H. Zhang, Y. Li, G. Adell, X.F. Sun, AIMM 17, 530–535 (2009)

X.J. Zhou, C.M. Liu, Y.H. Gao, S.N. Jiang, X.Z. Han, Z.Y. Chen, Metall. Mater. Trans. A 48, 3060–3072 (2017)

C.M. Sellars, Mater. Sci. Technol. 6, 1072–1081 (1990)

C.M. Sellars, Metal Sci. 13, 187–194 (1979)

T. Chandra, J.J. Jonas, Metall. Trans. 1, 2079–2082 (1970)

D.R. Askeland, W.J. Wright, Essentials of Materials Science & Engineering (Cengage Learning, Singapore, 2013), p. 233

J. Su, M. Sanjari, A.S.H. Kabir, I.H. Jung, J.J. Jonas, S. Yue, H. Utsunomiya, Mater. Sci. Eng. A 636, 582–592 (2015)

C.J. Chen, Q.D. Wang, D.D. Yin, J. Alloys Compd. 487, 560–563 (2009)

Author information

Authors and Affiliations

Corresponding author

Additional information

Available online at http://link.springer.com/journal/40195

Rights and permissions

About this article

Cite this article

Zhang, HX., Chen, SF., Cheng, M. et al. Modeling the Dynamic Recrystallization of Mg–11Gd–4Y–2Zn–0.4Zr Alloy Considering Non-uniform Deformation and LPSO Kinking During Hot Compression. Acta Metall. Sin. (Engl. Lett.) 32, 1122–1134 (2019). https://doi.org/10.1007/s40195-019-00898-z

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40195-019-00898-z