Abstract

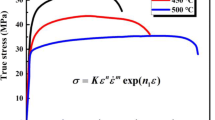

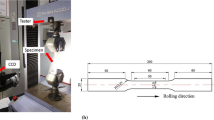

This study focused on the formability of aluminium alloy (7075-T6) sheets through hydroforming route. Formability of these sheets was tested using a warm forming setup at three different temperatures and four different die corner radii. Forming limit diagrams (FLD) were generated by measuring the grids of the sheet formed. The results show that the forming limit of AA7075-T6 can be significantly improved when the blank was heated to 140–250 °C. It was also observed that as the temperature increases above 140 °C, dome height began to decrease. Also the results indicated that both the die corner radius and temperature have a significant effect on the stress-strain curve and warm forming of AA7075-T6 sheets. Thus, with the temperature increased from room temperature (RT) to 140 °C, the flow stress decreased and the strain increased, hence, the formability is enhanced. However, further increase in temperature causes decreases the flow stress and strain. Similar changes of the flow curve were seen in die corner radius. Decreasing the die corner radius decreases the flow stress and increase the strain. Moreover, an equation was obtained by establishing correlations between the experimental parameters and their results. In this way, it became possible to make predictions.

Similar content being viewed by others

Abbreviations

- d b :

-

Sheet primitive diameter

- D c :

-

Die insert diameter

- t 0 :

-

Initial blank thickness

- t d :

-

Sheet thickness on dome zone

- R c :

-

Die fillet radius

- R d :

-

Dome radius of sheet

- h d :

-

Dome height

- p :

-

Pressure

- F c :

-

Blank holder force

- \(\bar \sigma\) :

-

Equivalent stress

- \(\bar \varepsilon\) :

-

Equivalent strain

- α :

-

Angle

- T :

-

Temperature

- a :

-

Die cavity radius

References

R. Neugebauer, T. Altan, M. Geiger, M. Kleiner and A. Sterzing, CIRP Ann. Manuf. Technol. 55 (2006) 793.

Y. Aoura, D. Ollivier, A. Ambari and P. Del Santo, J. Mater. Process. Technol. 145 (2004) 352.

M. Yaşar, I. Kadı and H. Evlen, in: 6th Int. Adv. Tech. Symp., IATS’11, Elazıǎ, Turkey, 2011, p.136. (in Turkish)

P. Cavaliere and A. Squillace, Mater. Charact. 55 (2005) 136.

V.X. Tran, J. Pan and T. Pan, J. Mater. Process. Technol. 209 (2009) 3724.

G.Z. Quan, K.W. Liu, J. Zhou and B. Chen, Trans. Nonferrous Met. Soc. China 19 (2009) 537.

A. Kandil, J. Mater. Process. Technol. 134 (2003) 70.

S.H. Zhang, L.H. Zhou, Z.T. Wang and Y. Xu, Int. J. Mach. Tools Manuf. 43 (2003) 781.

A. Dutta, I. Charit, L.B. Johannes and R.S. Mishra, Mater. Sci. Eng. A 395 (2005) 173.

O.F. Yenihayat, A. Mimaroglu and H. Unal, Mater. Des. 26 (2005) 73.

G. Venkateswarlu, M.J. Davidson and G.R.N. Tagore, Int. J. Eng. Sci. Technol. 2 (2010) 41.

A.T. Güneş, Press Work Technique, vol.2, Chamber of Mechanical Engineers, Ankara, 2002, pp.27–28. (in Turkish)

C.G. Erhuy, M.E. Yurci and T. Altan, J. Eng. Nat. Sci. 26 (2008) 281. (in Turkish)

G. Gutscher, H.C. Wu, G. Ngaile and T. Altan, J. Mater. Process. Technol. 146 (2004) 1.

M. Koç, E. Billur and Ö.N. Cora, Mater. Des. 32 (2011) 272.

E. Billur and M. Koç, in: Proceedings of the 2008 international manufacturing science and engineering conference MSEC2008, Evanston, IL, USA, 2008.

M. Koç, Y. Aueulan and T. Altan, Int. J. Mach. Tools Manuf. 41 (2001) 761.

K. Mori, S. Nishijima and C.J. Tan, Int. J. Mach. Tools Manuf. 49 (2009) 767.

S. Mahabunphachai and M. Koç, Mater. Des. 31 (2010) 2422.

H. Zhang, G.Y. Lin, D.S. Peng, L.B. Yang and Q.Q. Lin, J. Mater. Process. Technol. 148 (2004) 245.

P. Cavaliere, J. Light Met. 2 (2002) 247.

G. Liu, Z.J. Tang, Z.B. He and S.J. Yuan, Trans. Nonferrous Met. Soc. China 20 (2010) 2071.

Y.L. Lin, Z.B. He, S.J. Yuan and J. Wu, Trans. Nonferrous Met. Soc. China 21 (2011) 851.

H. Wang, Y.B. Luo, P. Friedman, M.H. Chen and L. Gao, Trans. Nonferrous Met. Soc. China 22 (2012) 1.

Z. He, S. Yuan, G. Liu, J. Wu and W. Cha, J. Mater. Process. Technol. 210 (2010) 877.

H.Ï Demirci and H. Evlen, J. Alloys Compd. 510 (2012) 26.

G. Ingarao, R. Di Lorenz and F. Micari, J. Clean. Prod. 19 (2011) 337.

W. Lee, K.H. Chung, D. Kim, J. Kim, C. Kim, K. Okamoto, R.H. Wagoner and K. Chung, Int. J. Plast. 25 (2009) 1626.

M. Keigler, H. Bauer, D. Harrison and A. De Silva, J. Mater. Process. Technol. 167 (2005) 363.

K. Chung, W. Lee, D. Kim, J. Kim, K.H. Chung, C. Kim, K. Okamoto and R.H. Wagoner, Int. J. Solids Struct. 47 (2010) 1048.

A.W. El-Morsy and K.I. Manabe, Mater. Lett. 60 (2006) 1866.

F.K. Chen, T.B. Huang and C.K. Chang, Int. J.Mach. Tools Manuf. 43 (2003) 1553.

Z. Marciniak, J.L. Duncan and S.J. Hu, Mechanics of Sheet Metal Forming, 2nd Ed, Butterworth-Heinemann, 2002, p.30.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Evlen, H., Kadı, İ. & Yaşar, M. Effects of die corner radius and temperature on the formability of AA7075-T6 alloy. ACTA METALL SIN 26, 623–629 (2013). https://doi.org/10.1007/s40195-013-0129-5

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40195-013-0129-5