Abstract

Contemporary industrial practice takes wide advantage of adhesive materials and adhesive bonding techniques, notably in the aviation and automotive industries. The geometry of bonded joints may vary considerably, and this paper explores the potential advantages of S-shaped lapped profiles with particular reference to the slope of the S. This aspect of the joint offers improvements in the area of adhering surfaces and provides superior bonding in comparison with conventional single lap joints.

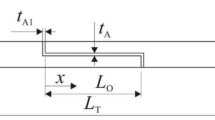

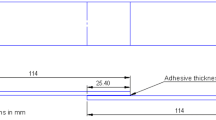

The study examines 30-mm overlapping specimen joints made from 100-mm-length by 25-mm-width AA 2024-T3 aluminium alloy sheets, having alternative thicknesses of 6.5, 10 and 13.5 mm. It also features three alternative radii for the profiles, thus generating different slopes for the S-shapes. The specimen joints were bonded using acrylic adhesive DP 810, modelled using finite element analysis and subjected to physical confirmation of the analysis results. The results show that a decrease in profile radius correlates with an increase in failure load; that an increase in profile radius lessens the effect of thickness on damage load and that bending moment is absent from the adhesive bonding profile of the S-shape.

Similar content being viewed by others

References

Ribeiro TEA, Campilho RDSG, da Silva LFM, Goglio L (2016) Damage analysis of composite–aluminium adhesively-bonded single-lap joints. Compos Struct 136:25–33. https://doi.org/10.1016/j.compstruct.2015.09.054

Khoramishad H, Razavi SMJ (2014) Metallic fiber-reinforced adhesively bonded joints. Int J Adhes Adhes 55:114–122. https://doi.org/10.1016/j.ijadhadh.2014.08.005

He X (2011) A review of finite element analysis of adhesively bonded joints. Int J Adhes Adhes 31:248–264. https://doi.org/10.1016/j.ijadhadh.2011.01.006

da Silva LFM, Öchsner A, Adams RD (2011) Handbook of adhesion technology. Springer, Springer- Verlag Berlin Heidelberg

da Silva LFM, Pirondi A, Öchsner A (2011) Hybrid adhesive joints. Springer-Verlag, Berlin Heidelberg

Liu X, Wang G (2007) Progressive failure analysis of bonded composite repairs. Compos Struct 81:331–340. https://doi.org/10.1016/j.compstruct.2006.08.024

Nguyen T-C, Bai Y, Zhao X-L, Al-Mahaidi R (2011) Mechanical characterization of steel/CFRP double strap joints at elevated temperatures. Compos Struct 93:1604–1612. https://doi.org/10.1016/j.compstruct.2011.01.010

Temiz Ş (2006) Application of bi-adhesive in double-strap joints subjected to bending moment. J Adhes Sci Technol 20:1547–1560. https://doi.org/10.1163/156856106778884262

Nguyen T-C, Bai Y, Zhao X-L, Al-Mahaidi R (2012) Durability of steel/CFRP double strap joints exposed to sea water, cyclic temperature and humidity. Compos Struct 94:1834–1845. https://doi.org/10.1016/j.compstruct.2012.01.004

Ascione F (2016) The influence of adhesion defects on the collapse of FRP adhesive joints. Composites Part B 87:291–298. https://doi.org/10.1016/j.compositesb.2015.10.033

Qian H (2008) A study of failure in bonded lap joints using fracture mechanics. Ph.D.

Demir Aydin M, Akpinar S (2014) The strength of the adhesively bonded T-joints with embedded supports. Int J Adhes Adhes 50:142–150. https://doi.org/10.1016/j.ijadhadh.2013.12.028

Ascione F, Mancusi G, Spadea S, Lamberti M, Lebon F, Maurel-Pantel A (2015) On the flexural behaviour of GFRP beams obtained by bonding simple panels: an experimental investigation. Compos Struct 131:55–65. https://doi.org/10.1016/j.compstruct.2015.04.039

Ascione F, Lamberti M, Razaqpur AG, Spadea S (2017) Strength and stiffness of adhesively bonded GFRP beam-column moment resisting connections. Compos Struct 160:1248–1257. https://doi.org/10.1016/j.compstruct.2016.11.021

Zhan X, Gu C, Wu H, Liu H, Chen J, Chen J, Wei Y (2016) Experimental and numerical analysis on the strength of 2060 Al–Li alloy adhesively bonded T joints. Int J Adhes Adhes 65:79–87. https://doi.org/10.1016/j.ijadhadh.2015.11.010

Haghpanah B, Chiu S, Vaziri A (2014) Adhesively bonded lap joints with extreme interface geometry. Int J Adhes Adhes 48:130–138. https://doi.org/10.1016/j.ijadhadh.2013.09.041

Ashrafi M, Ajdari A, Rahbar N, Papadopoulos J, Nayeb-Hashemi H, Vaziri A (2012) Adhesively bonded single lap joints with non-flat interfaces. Int J Adhes Adhes 32:46–52. https://doi.org/10.1016/j.ijadhadh.2011.09.004

Li J, Yan Y, Zhang T, Liang Z (2015) Experimental study of adhesively bonded CFRP joints subjected to tensile loads. Int J Adhes Adhes 57:95–104. https://doi.org/10.1016/j.ijadhadh.2014.11.001

Çitil Ş, Ayaz Y, Temiz Ş (2017) Stress analysis of adhesively bonded double strap joints with or without intermediate part subjected to tensile loading. J Adhes 93:343–356. https://doi.org/10.1080/00218464.2015.1075885

Çitil Ş, Temiz Ş, Altun H, Özel A (2011) Determination of mechanical properties of double-strap adhesive joints with an embedded patch. J Adhes Sci Technol 25:2555–2567. https://doi.org/10.1163/016942411X580225

Ayaz Y, Çitil Ş, Şahan MF (2016) Repair of small damages in steel pipes with composite patches. Mater Werkst 47:503–511. https://doi.org/10.1002/mawe.201600526

Çitil Ş, Ayaz Y, Temiz Ş, Aydın MD (2017) Mechanical behaviour of adhesively repaired pipes subject to internal pressure. Int J Adhes Adhes 75:88–95. https://doi.org/10.1016/j.ijadhadh.2017.02.015

Çitil Ş (2017) Comparison of stepped, curved, and S-type lap joints under tensile loading. Adv Struct Mat :377–388. https://doi.org/10.1007/978-3-319-50784-2_28

Akpinar S, Temiz Ş, Aydin MD, Özel A (2012) Effect of protrusion at the ends of bondline in single lap joints under tension and bending. J Adhes Sci Technol 26:2591–2602. https://doi.org/10.1080/01694243.2012.691002

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Recommended for publication by Commission XVI - Polymer Joining and Adhesive Technology

Rights and permissions

About this article

Cite this article

AYAZ, Y. Effect of slope in S-type adhesive bonding under axial loading. Weld World 63, 1443–1448 (2019). https://doi.org/10.1007/s40194-019-00756-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40194-019-00756-7