Abstract

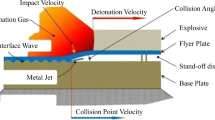

In this paper, the effect of initial tensile strength on the explosive welding interface morphology and welding quality was studied. The plates with different initial tensile strength were fabricated via the explosive welding method under the same parameters. Microstructure and hardness at the interface were obtained. According to the characterization, the results demonstrated the morphology of the cross sections is greatly influenced by the strength of the plates. Microhardness analysis confirms that the explosive joining section has work hardening and thermal softening effect occurred. Furthermore, the explosive welding process was numerically simulated by AUTODYN and the temperature distribution of the interfaces was obtained, and it reveals that the strength is negligible and the interface can only be considered as incompressible flow when the pressure ratio \( \overline{\sigma} \) is large enough. Otherwise, the strength of the plates cannot be neglected.

Similar content being viewed by others

References

Bataev IA, Lazurenko DV, Tanaka S, Hokamoto K, Bataev AA, Guo Y, Jorge AM Jr (2017) High cooling rates and metastable phases at the interfaces of explosively welded materials. Acta Mater 135:277–289. https://doi.org/10.1016/j.actamat.2017.06.038

Liu C, Shanthraj P, Diehl M, Roters F, Dong S, Dong J, Ding W, Raabe D (2018) An integrated crystal plasticity–phase field model for spatially resolved twin nucleation, propagation, and growth in hexagonal materials. Int J Plast 106:203–227. https://doi.org/10.1016/j.ijplas.2018.03.009

Paul H, Morgiel J, Baudin T, Brisset F, Prażmowski M, Miszczyk M (2014) Characterization of explosive weld joints by TEM and SEM/EBSD. Arch Metall Mater 59:1129–1136. https://doi.org/10.2478/amm-2014-0197

Mali VI, Bataev AA, Maliutina IN, Kurguzov VD, Bataev IA, Esikov MA, Lozhkin VS (2017) Microstructure and mechanical properties of Ti/Ta/Cu/Ni alloy laminate composite materials produced by explosive welding. Int J Adv Manuf Technol 93:1–10. https://doi.org/10.1007/s00170-017-0887-8

Vigueras D (2007) Explosive and impact welding: technical review. Mater Technol 22:200–204. https://doi.org/10.1179/175355507X236740

Bahrani AS, Black TJ, Crossland B (1967) The mechanics of wave formation in explosive welding. Proc R Soc A: Mathematical, Physical and Engineering Sciences 296:123–136. https://doi.org/10.1098/rspa.1967.0010

Reid SR (1978) Wake instability mechanism for wave formation in explosive welding. Int J Mech Sci 20:247–253. https://doi.org/10.1016/0020-7403(78)90086-3

Chemin C, Qingming T (1989) Mechanism of wave formation at the interface in explosive welding. Acta Mech Sinica 5:97–108. https://doi.org/10.1007/BF02489134

Aizawa Y, Nishiwaki J, Harada Y, Muraishi S, Kumai S (2016) Experimental and numerical analysis of the formation behavior of intermediate layers at explosive welded Al/Fe joint interfaces. J Manuf Process 24:100–106. https://doi.org/10.1016/j.jmapro.2016.08.002

Ribeiro JB, Mendes R, Loureiro A (2014) Review of the weldability window concept and equations for explosive welding. J Phys Conf Ser 500:38. https://doi.org/10.1088/1742-6596/500/5/052038

Zhou Q, Feng J, Chen P (2017) Numerical and experimental studies on the explosive welding of tungsten foil to copper. Materials 10:E984. https://doi.org/10.3390/ma10090984

Li K, Li X, Yan H, Wang X, Wang Y (2018) Study of continuous velocity probe method for the determination of the detonation pressure of commercial explosives. J Energ Mater 00:1–9. https://doi.org/10.1080/07370652.2018.1425310

Wang Y, Beom HG, Sun M, Lin S (2011) Numerical simulation of explosive welding using the material point method. Int J Impact Eng 38:51–60. https://doi.org/10.1016/j.ijimpeng.2010.08.003

Li XJ, Mo F, Wang XH, Wang B, Liu KX (2012) Numerical study on mechanism of explosive welding. Sci Technol Weld Join 17:36–41. https://doi.org/10.1179/1362171811Y.0000000071

Sun W, Li XJ, Hokamoto K (2013) Numerical simulation of underwater explosive welding process. Mater Sci Forum 767:120–125. https://doi.org/10.4028/www.scientific.net/MSF.767.120

Akbari M, Saedodin S, Toghraie D, Shoja-Razavi R, Kowsari F (2014) Experimental and numerical investigation of temperature distribution and melt pool geometry during pulsed laser welding of Ti6Al4V alloy. Opt Laser Technol 59:52–59. https://doi.org/10.1016/j.optlastec.2013.12.009

Akbari Mousavi SAA, Farhadi Sartangi P (2009) Experimental investigation of explosive welding of cp-titanium/AISI 304 stainless steel. Mater Des 30:459–468. https://doi.org/10.1016/j.matdes.2008.06.016

Yan YB, Zhang ZW, Shen W, Wang JH, Zhang LK, Chin BA (2010) Microstructure and properties of magnesium AZ31B-aluminum 7075 explosively welded composite plate. Mater Sci Eng A 527:2241–2245. https://doi.org/10.1016/j.msea.2009.12.007

Jinlong L, Tongxiang L, Limin D, Chen W (2016) Influence of sensitization on microstructure and passive property of AISI 2205 duplex stainless steel. Corros Sci 104:144–151. https://doi.org/10.1016/j.corsci.2015.12.005

Mohammed G, Ishak M, Aqida S, Abdulhadi H (2017) Effects of heat input on microstructure, corrosion and mechanical characteristics of welded austenitic and duplex stainless steels: a review. Metals 7:39. https://doi.org/10.3390/met7020039

Sun W, Li X, Yan H, Hokamoto K (2014) Effect of initial hardness on interfacial features in underwater explosive welding of tool steel SKS3. J Mater Eng Perform 23:421–428. https://doi.org/10.1007/s11665-013-0778-6

Funding

This work was supported by the Natural Science Foundation of China (Nos. 11672067 and 11672068).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Recommended for publication by Commission II - Arc Welding and Filler Metals

Rights and permissions

About this article

Cite this article

Zeng, Xy., Li, Xj., Chen, X. et al. Numerical and experimental studies on the explosive welding of plates with different initial strength. Weld World 63, 967–974 (2019). https://doi.org/10.1007/s40194-019-00733-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40194-019-00733-0