Abstract

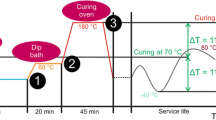

Lightweight construction methods will make a significant contribution to sustainable CO2 reduction in new car body developments. Multi-material design offers cost-efficient lightweight solutions for car mass production. The key to successfully drive this development trend is a particularly economical, safe and sustainable joining technique: adhesive bonding. In automotive production, the car body must be heated in an oven to ensure the curing process of the adhesives. The increase in temperature leads to different expansion performance of adherends according to their individual thermal expansion behaviour. Stresses occurring may be so great as to cause plastic deformation in the joint area. During cooling of the bonded construction, further relative displacements occur between the joint partners, which can lead to joint failure. These effects influence the usability, sustainability and long-term durability of adhesively bonded components and have not yet been considered for use in automotive car body design. As part of a research project, a test stand was built to allow adhesive bonds to be cured under diverse selected temperature-time profiles e.g. to simulate the cathodic dip-paint process. Various degrees of adhesive curing can be realized and the influence on the joint evaluated in a subsequent tensile test. Parameters such as the maximum strength or displacement at fracture, but also the plastic deformation behaviour of the used toughened adhesive system, depend on the degree of curing. Temperature-related relative displacements are simulated by applying an additional mechanical stress during adhesive curing. Their influence on the mechanical properties of the adhesive bond is evaluated in a subsequent tensile test. There is a significant influence of relative displacement on the mechanical behaviour of the adhesive joint during adhesive curing.

Similar content being viewed by others

References

Schmidt, M., Fehling, E.: Ultra-HochfesterBeton – Planung und Bau der ersten Brücke mit UHPC in Europa. Schriftenreihe Baustoffe und Massivbau Heft 2 Kassel University Press, 2007

Feldmann, M., Pilsl, M.-Langosch, K.: Der neue Glashof des Jüdischen Museum Berlin. Stahlbau Spezial (2008) S. 34–41

Neubauer G, Schober KP (2009) Holz-Glas-Verbundkonstruktionen. Adhäsion 7–8:42–44

Schlimmer, M., Bornemann, J.: Zeitabhängiges Verhalten elektrisch leitfähiger Klebverbindungen unter thermomechanischer Beanspruchung. Abschlussbericht zum AiF/DVS Forschungsprojekt Nr. 13.593 N, Deutscher Verband für Schweißen und verwandte Verfahren e. V. Düsseldorf 2007

Enns JB, Gillham JK (1983) Time-temperature-transformation cure diagram: modelling the cure behaviour of thermosets. J Appl Polym Sci 28:2567–2591

Harsch, M.: Methoden und Ansätze zur spannungsarmen Vernetzung von Epoxidharzen. IVW-Schriftenreihe Bd. 76, Kaiserslautern, 2008

White SR, Hahn HT (1992) Process modelling of composite materials: residual stress development during cure. J Compos Mater 26:2402–2453

Adolf DB, Martin JE (1966) Calculating of stress in crosslinking polymers. J Compos Mater 30:13–34

Adolf DB, Chambers RS (2007) A thermodynamically consistent, nonlinear viscoelastic approach for modelling thermosets during cure. J Rheol 51:23–50

Hahn O, Jendrny J (2003) Evaluation on simulation models for the estimation of deformation of adhesively bonded steel sheets during curing. Welding in the World 47(7–8):31–38

Jendrny, J.: Entwicklung von Berechnungsmodellen zur Abschätzung der Verformung geklebter dünnwandiger Stahlbauteile in Leichtbaukonstruktionen während der Warmaushärtung. Schriftenreihe P 513 der Forschungsvereinigung Stahlanwendung e.V., Düsseldorf, 2004

Hahn, O. Jendrny, J. Figge, V. Einfluss des Fertigungsprozesses auf die Verbindungseigenschaften geklebter Hybridstrukturen, Tagungsband des 1. Berichtskolloquiums der DFG-Forschergruppe Hochleistungsfügetechnik für Hybridstrukturen“, Hannover, S. 64–73.

Van’t Hof, C. Mechanical Characterization and Modelling of Curing Thermosets, Schriftenreihe der University of Technology, Delft, 2006

Patankar KA, Dillard DA, Fernholz KD (2013) Characterizing the constitutive properties and developing a stress model for adhesive bond-line readout. Int J Adhes Adhes 40:149–157

Schlimmer, M., Hahn, O. Hennemann, O.-D. Methodenentwicklung zur Berechnung und Auslegung geklebter Stahlbauteile für den Fahrzeugbau. Abschlussbericht zum AiF/FOSTA ZUTECH-Forschungsprojekt 76 ZN, Forschungsvereinigung Stahlanwendung e.V., Düsseldorf, 2004

Zhang J, Guo Q, Fox B (2009) Structural and material properties of a rapidly cured thermoplastic-toughened epoxy system. J Appl Polym Sci 113:485–491

Da Silva, L.F.M., Adams, R. D., u. a. Analytical Models of adhesively bonded joints. Part I: Literature survey, Part II: Comparative Study. Int. J. Adhesion & Adhesives29 (2009) S. 319–330, 331–341

Schlimmer, M. Klebverbindungen - Versuch und Simulation. 6. LS-DYNA Forum Frankental 11.-12.10.2007

Schlimmer M, Mahnken R (2005) Simulation of strength difference in elasto-plasticity for adhesive materials. Int J Numer Methods Eng 63:1461–1477

Hahn, O., Schlimmer, M.: Unpublished research results

Lion A, Höfer P (2007) On the phenomenological representation of curing phenomena in continuum mechanics. Archives of Mechanics 59:59–89

Diercks N (2009) Validation and ANSYS implementation of the Schlimmer-Mahnken material model ANSYS Conference & 27th CADFEM Users Meeting, Leipzig

Matzenmiller A, Gerlach S, Fiolka M (2006) Progressive failure analysis of adhesively bonded joints in crash simulations, Konferenzbeitrag zum 5. LS-DYNA FORUM, Ulm

Acknowledgments

The IGF research project 369 ZN (FOSTA P 878) by Forschungsvereinigung Stahlanwendung e.V. - FOSTA, Sohnstraße 65, 40237 Düsseldorf, Germany, is funded by the AiF under the programme for promotion of industrial research (IGF) by the Federal Ministry for Economic Affairs and Energy based on a decision of the German Bundestag.

Author information

Authors and Affiliations

Corresponding author

Additional information

Doc. IIW-2507, recommended for publication by Commission XVI “Polymer Joining and Adhesive Technology.”

Rights and permissions

About this article

Cite this article

Meschut, G., Hahn, O. & Teutenberg, D. Influence of the curing process on joint strength of a toughened heat-curing adhesive. Weld World 59, 209–216 (2015). https://doi.org/10.1007/s40194-014-0195-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40194-014-0195-y