Abstract

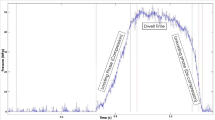

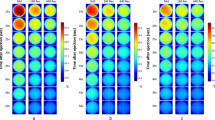

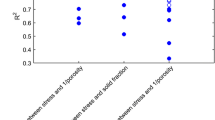

Tablet compaction is an important unit operation in the pharmaceutical industry. Among the compaction parameters, dwell time is a key parameter that has been consistently been shown to impact the mechanical quality of tablets. Compacts experience a state of relatively constant strain during the dwell phase and this allows time dependent reactions such as viscoelastic flow to take place within the tablet microstructure. The importance of time dependent compact deformation during the dwell phase has been extensively researched over the years. The amount of plastic flow during the dwell phase has been quantified by researchers by calculating the amount of compaction force decay from stress relaxation curves and by determining certain deformation parameters from compaction force–time profiles during high speed tableting. Dwell time prolongation often led to significant enhancements in the mechanical strength of the tablets, due to a favorable time-dependent shift in the elastic–plastic equilibrium in the compact. The influence of dwell phase on tablet properties is governed by the predominant deformation properties of constituents being compressed along with other coexisting compaction parameters such as strain rate during the consolidation phase of the compaction cycle. Research work on the impact of dwell time on tablet compaction in conjunction with formulation and process variables are useful as the findings that are representative of manufacturing conditions would be useful for understanding of the compaction process especially in high speed tableting. Press or tool designs may also be accentuated at increasing dwell time without compromising tablet production rate.

Similar content being viewed by others

References

Akande OF, Rubinstein MH, Rowe PH, Ford JL (1997) Effect of compression speeds on the compaction properties of a 1:1 paracetamol–microcrystalline cellulose mixture prepared by single compression and by combinations of pre-compression and main-compression. Int J Pharm 157:127–136

Akande OF, Ford JL, Rowe PH, Rubinstein MH (1998) The effects of lag-time and dwell-time on the compaction properties of 1:1 paracetamol/microcrystalline cellulose tablets prepared by pre-compression and main compression. J Pharm Pharmacol 50:19–28

Anbalagan P, Sarkar S, Liew CV, Heng PW (2016) Influence of the punch head design on the physical quality of tablets produced in a rotary press. J Pharm Sci 106:356–365

Armstrong NA, Palfrey LP (1989) The effect of machine speed on the consolidation of four directly compressible tablet diluents. J Pharm Pharmacol 41:149–151

American Pharmacists Association (2006) Tableting specification manual. American Pharmacists Association, Iowa City

Augsburger LL, Hoag SW (2008) Pharmaceutical dosage forms: Tablets. Informa Healthcare, New York

Celik M (2011) Pharmaceutical powder compaction technology. Informa Healthcare, New York

Cole ET, Rees JE, Hersey JA (1975) Relations between compaction data for some crystalline pharmaceutical materials. Pharm Acta Helv 50:28–32

Courtoy (2014) GEA-Courtoy tabletting equipment. Available from http://www.s3process.co.uk/solid-dosage/gea-courtoy/tabletting. Accessed 11 Dec 2016

David ST, Augsburger LL (1977) Plastic flow during compression of directly compressible fillers and its effect on tablet strength. J Pharm Sci 66:155–159

Dwivedi SK, Oates RJ, Mitchell AG (1991) Peak offset times as an indication of stress relaxation during tableting on a rotary tablet press. J Pharm Pharmacol 43:673–678

Ebba F, Piccerelle P, Prinderre P, Opota D, Joachim J (2001) Stress relaxation studies of granules as a function of different lubricants. Eur J Pharm Biopharm 52:211–220

Garekani HA, Ford JL, Rubinstein MH, Rajabi-Siahboomi AR (2001) Effect of compression force, compression speed, and particle size on the compression properties of paracetamol. Drug Dev Ind Pharm 27:935–942

Garr JSM, Rubinstein MH (1991) An investigation into the capping of paracetamol at increasing speeds of compression. Int J Pharm 72:117–122

Hyunjo K, Gopi V (2005) Original articles : Compaction simulator study on pectin introducing dwell time. Int J Pharm Investig 35:243–247

Ishino R, Yoshino H, Hirakawa Y, Noda K (1990) Influence of tabletting speed on compactibility and compressibility of two direct compressible powders under high speed compression. Chem Pharm Bull 38:1987–1992

Konkel P, Mielck JB (1998) Associations of parameters characterizing the time course of the tabletting process on a reciprocating and on a rotary tabletting machine for high-speed production. Eur J Pharm Biopharm 45:137–148

Korsch (2016) High speed, fully automated production. Available from http://www.korsch.de/en/applications/pharmaceutical-industry/production. Accessed 11 Dec 2016

Leitritz M, Krumme M, Schmidt PC (1996) Force-time curves of a rotary tablet press. Interpretation of the compressibility of a modified starch containing various amounts of moisture. J Pharm Pharmacol 48:456–462

Marshall PV, York P, Maclaine JQ (1993) An investigation of the effect of the punch velocity on the compaction properties of ibuprofen. Powder Technol 74:171–177

Natoli (2016) How crucial is compaction dwell time? Available from https://natoli.com/how-crucial-is-compaction-dwell-time/. Accessed 11 Dec 2016

Rees JE, Rue PJ (1978) Time-dependent deformation of some direct compression excipients. J Pharm Pharmacol 30:601–607

Rehula M, Adamek R, Spacek V (2012) Stress relaxation study of fillers for directly compressed tablets. Powder Technol 217:510–515

Roberts RJ, Rowe RC (1985) The effect of punch velocity on the compaction of a variety of materials. J Pharm Pharmacol 37:377–384

Roberts RJ, Rowe RC (1986) The effect of the relationship between punch velocity and particle size on the compaction behaviour of materials with varying deformation mechanisms. J Pharm Pharmacol 38:567–571

Ruegger CE, Celik M (2000) The effect of compression and decompression speed on the mechanical strength of compacts. Pharm Dev Technol 5:485–494

Sarkar S, Ooi SM, Liew CV, Heng PW (2015) Influence of rate of force application during compression on tablet capping. J Pharm Sci 104:1319–1327

Schmidt PC, Leitritz M (1997) Compression force/time-profiles of microcrystalline cellulose, dicalcium phosphate dihydrate and their binary mixtures—a critical consideration of experimental parameters. Eur J Pharm Biopharm 44:303–313

Schmidt PC, Vogel PJ (1994) Force-time-curves of a modern rotary tablet machine I. Evaluation techniques and characterization of deformation behaviour of pharmaceutical substances. Drug Dev Ind Pharm 20:921–934

Shlanta S, Milosovich G (1964) Compression of pharmaceutical powders I. Theory and instrumentation. J Pharm Sci 53(5):562–564

Tye CK, Sun CC, Amidon GE (2005) Evaluation of the effects of tableting speed on the relationships between compaction pressure, tablet tensile strength, and tablet solid fraction. J Pharm Sci 94:465–472

Van der Voort Maarschalk K, Zuurman K, Vromans H, Bolhuis GK, Lerk CF (1997) Stress relaxation of compacts produced from viscoelastic materials. Int J Pharm 151:27–34

Vezin WR, Pang HM, Khan KA, Malkowska S (1983) The effect of precompression in a rotary machine on tablet strength. Drug Dev Ind Pharm 9:1465–1474

Vogel PJ, Schmidt PC (1993) Force-time curves of a modern rotary tablet machine II. Influence of compression force and tableting speed on the deformation mechanisms of pharmaceutical substances. Drug Dev Ind Pharm 19:1917–1930

Xu M, Heng PW, Liew CV (2016) Formulation and process strategies to minimize coat damage for compaction of coated pellets in a rotary tablet press: a mechanistic view. Int J Pharm 499:29–37

Acknowledgements

Parthiban Anbalagan is a recipient of the National University of Singapore Graduate Research Scholarship. Financial support for the project was from the GEA-NUS PPRL fund (N-148-000-008-001).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

All authors (P. Anbalagan, C. V. Liew and P. W. S. Heng) declare that they have no conflict of interest.

Rights and permissions

About this article

Cite this article

Anbalagan, P., Liew, C.V. & Heng, P.W.S. Role of dwell on compact deformation during tableting: an overview. Journal of Pharmaceutical Investigation 47, 173–181 (2017). https://doi.org/10.1007/s40005-017-0306-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40005-017-0306-z