Abstract

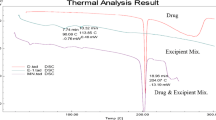

The co-processing is most widely explored method for development of directly compressible excipients. The present research was focused on development of co-processed excipients for fast dissolving tablets of Irbesartan by melt agglomeration technique. From the preliminary trials Lactose monohydrate and mannitol was selected as a diluent and Poly ethylene glycol 4000 as binder. To improve functionality of co-processed excipients 8 % crospovidone was incorporated. Diluent blend ratio and concentration of binder (%) were selected as independent variables in central composite design. The agglomerates were evaluated in terms of % fines, angle of repose, Carr’s index, Hausner ratio. The tablets were manufactured on a rotary press and their friability, tensile strength and disintegration time were evaluated. This optimized batch was characterized by means of the granular friability index, Heckel analysis, Kawakita, Kuno’s analysis, lubricant sensitivity ratio and a dilution potential study. Result of dilution potential showed that up to 40 % drug can be incorporated. In addition to these, bitter taste of drug was masked by forming drug—β-cyclodextrin inclusion complex and by adding aspartame as a Sweetener. Compared to conventional tablet it showed faster dissolution. Instrumental studies like Fourier transform-infrared spectroscopy, differential scanning calorimetry, X-ray diffraction showed that the compatibility of various excipients with drug. The present study underlines the fact that melt granulation technique may be adopted for the development of directly compressible adjuvant for use in pharmaceuticals.

Similar content being viewed by others

References

Abbaraju PL, Meka AK, Vamshi MK, Annie VK, Ashwini G (2012) Formulation and development of Irbesartan (poorly water soluble drug) immediate release tablets. Int Res J Pharm 3:117–120

Daraghmeh N, Rashid I, Omari MH, Leharne SA, Chowdhry BZ, Badwan A (2010) Preparation and characterization of a novel co-processed excipients of chitin and mannitol. AAPS PharmSciTech 11:1558–1571

Garala K, Patel J, Patel A, Raval M, Dharmsi A (2012) Influence of excipients and processing conditions on the development of agglomerates of racecadotril by crystallo-co-agglomeration. Int J Pharm Investig 2:189–200

Gohel MC (2005) A review of co-processed directly compressible excipients. J Pharm Pharm Sci 8:76–93

Gohel MC, Jogani PD (2003) Exploration of melt granulation technique for the development of co-processed directly compressible adjuvant containing lactose and microcrystalline cellulose. Pharm Dev Technol 8:175–185

Gohel MC, Patel M, Amin A, Agrawal R, Dave R, Bariya N (2004) Formulation design and optimization of mouth dissolve tablets of nimesulide using vacuum drying technique. AAPS Pharm SciTeh 5:1–6

Hirlekar R, Kadam V (2009) Preformulation study of the inclusion complex Irbesartan-β-cyclodextrin. AAPS PharmSci Tech 10:276–281

Jagdale SW, Gawali VU, Kuchekar BS, Chabukswar AR (2011) Formulation and in vitro evaluation of taste-masked oro-dispersible dosage form of diltiazem hydrochloride. Pharm Sci 47:907–916

Karthikeyan M, Mukhthar AK, Hamza PS (2011) Formulation of diclofenac tablets for rapid pain relief. Asian Pac J Trop Dies 5308–5311

Khan A, Iqbal Z, Rehman Z, Nasir F, Khan A, Ismail M, Mohammad A (2013) Application of SeDem expert system in formulation development of effervescent tablets by direct compression. Saudi Pharm J

Nokhodchi A, Maghsoodi M (2008) Preparation of spherical crystal agglomerates of naproxen containing disintegrant for direct tablet making by spherical crystallization technique. AAPS PharmSciTech 9:54–59

Patel SS, Patel NM (2009) Development of directly compressible co-processed excipient for dispersible tablets using 32 full factorial design. Int J Pharm Pharm Sci 1:125–148

Patel SS, Patel NM, Soniwala MM (2009) Statistical development of a multifunctional directly compressible co-processed excipient using the melt agglomeration technique. Asian J Pharm Sci 4:340–356

Pathan IB, Shingare PR, Kurumkar P (2013) Formulation design and optimization of novel mouth dissolving tablets for venlafaxine hydrochloride using sublimation technique. J Pharm res 6:593–598

Prajapati S, Patel P, Patel C (2012) Formulation and evaluation of sublingual tablets containing sumatriptan succinate. Int J Pharm Investig 2:162–168

Saha S, Shahivala A (2009) Multifunctional coprocessed excipients for improved tabletting performance. Expert Opin Drug Deliv 6:197–208

Singh S, Shah D (2010) Development and characterization of mouth dissolving tablet of Zolmitriptan. Asian Pac J Trop Dies S457–S464

U. S. Pharmacopoeia, “Carr’s Index” Nov 2012, www.pharmacopoeia.cn/v29240/usp29nf2450-c1174.html

U. S. Pharmacopoeia, “Angle of repose” Nov 2012, www.pharmacopoeia.cn/v29240/usp29nf2450-c1174.htm

Acknowledgments

This article does contain Taste masking study with human subjects performed by the authors. All authors (Kothiya Madhvi, Kuldeep Mehta, K. R. Vadalia, Chavda Jay, Kapadiya Sandip) declare that they have no conflict of interest. We would like to thank the company CTX Lifescience Pvt. Ltd., Surat. for giving us the free gift samples of Irbesartan. We are also thankful to Gujarat microwax Pvt. Ltd. Ahmedabad, Chemdyes corporation Rajkot, Anil Limited Ahmedabad, Central Institute of Fisheries Technology Cochin, Maple Biotech Pvt. Ltd Pune, Apex Healthcare Limited Ankleshwar and Gangwal Chemicals Pvt. Ltd Mumbai for providing free gift sample of excipients. We would like to thanks also the following institutes Shree M. N. Virani Science College, Rajkot for FTIR study and Saurashtra University Department of Pharmacy, rajkot for DSC study.

Author information

Authors and Affiliations

Corresponding authors

Rights and permissions

About this article

Cite this article

Madhvi, K., Mehta, K., Vadalia, K.R. et al. Design and development of co-processed excipients for fast dissolving tablets of Irbesartan by melt agglomeration technique. Journal of Pharmaceutical Investigation 45, 163–186 (2015). https://doi.org/10.1007/s40005-014-0163-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40005-014-0163-y