Abstract

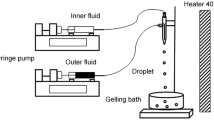

This study is focused on the preparation of n-nonadecane-loaded calcium alginate capsules by coaxial electrospray technique. The solution and process parameters such as sodium alginate concentration, polymer feeding rate, needle gauge, needle length, needle-to-collector distance, and stirring speed were optimized through Taguchi method. These parameters were selected as variables, and three levels of them were introduced into L27 orthogonal arrays. Taguchi’s signal-to-noise ratio and analysis of variance were used to minimize the response and find the effect of control factors on it, respectively. The setup of the two-axial nozzle and feed rates of core/shell solutions were studied, as well. Optical microscopy, scanning electron microscopy (SEM), and Fourier transform infrared (FTIR) spectroscopy were used for characterization of the capsules. The results showed that the sodium alginate concentration and the needle gauge are important factors for capsulated alginate material. The optical microscope images and the FTIR spectra confirmed that the alginate shell successfully fabricated the n-nonadecane materials. SEM analysis showed that at the optimal conditions, micro- and nano-capsules were prepared with nearly spherical shape. The results showed that when the inner needle tip was displaced 0.5 mm ahead of the tip of the outer needle, the envelopment of the core polymer was better accomplished by the outer polymer.

Similar content being viewed by others

References

Regin AF, Solanki SC, Saini JS (2008) Heat transfer characteristics of thermal energy storage system using PCM capsules; a review. Renew Sust Energy Rev 12:2438–2458

McCann JT, Marquez M, Xia Y (2006) Melt coaxial electrospinning: a versatile method for the encapsulation of solid materials and fabrication of phase change nanofibers. Nano Lett 6:2868–2872

Farid MM, Khudhair AM, Razack SAK, Al- Hallaj S (2004) A review on phase change energy storage: materials and applications. Energ Convers Manag 45:1597–1615

Sarı A, Alkan C, Karaipekli A (2010) Preparation, characterization and thermal properties of PMMA/n-heptadecane microcapsules as novel solid–liquid microPCM for thermal energy storage. Appl Energy 87:1529–1534

Alay S, Alkan C, Gödec F (2011) Synthesis and characterization of poly(methyl methacrylate)/n-hexadecane microcapsules using different cross-linkers and their application to some fabrics. Thermochim Acta 518:1–8

Alkan C, Sari A, Karaipekli A, Uzun O (2009) Preparation, characterization, and thermal properties of microcapsulated phase change materials for thermal energy storage. Sol Energy Mater Sol Cells 93:143–147

Onder E, Sarier N, Cimen E (2008) Encapsulation of phase change material by complex coacervation to improve thermal performances of woven fabrics. Thermochim Acta 467:63–72

Hawlader MNA, Uddin MS, Khim MM (2003) Microcapsulated pcm thermal—energy storage systems. Appl Energy 74:195–202

Chaiyasat A, Waree C, Songkhamrod K, Sirithip P, Voranuch V, Chaiyasat P (2012) Preparation of polydivinylbenzene/natural rubber capsule encapsulating octadecane: influence of natural rubber molecular weight and content. EXPRESS Polym Lett 6:70–77

Sánchez L, Sánchez P, Lucas Ad, Carmona M, Rodríguez JF (2007) Microencapsulation of PCMs with a polystyrene shell. Colloid Polym Sci. doi:10.1007/s00396-007-1696-7

Zhanga XX, Fan YF, Tao XM, Yickb KL (2004) Fabrication and properties of microcapsules and nanocapsules containing n-octadecane. Mater Chem Phys 88:300–307

Fang Y, Kuang S, Gao X, Zhang Z (2008) Preparation and characterization of novel nanoencapsulated phase change materials. Energy Convers Manag 49:3704–3707

Tseng YH, Fang MH, Tsai PS, Yang YM (2005) Preparation of microencapsulated phase change materials (mcpcms) by means of interfacial polycondensation. J Microencapsul 22:37–46

Liu Y, Chen X, Xin JH (2006) Silica nanoparticles-walled microcapsules. J Mater Sci 41:5399–5401

Moghaddam MK, Mortazavi SM, Khayamian T (2014) Preparation of calcium alginate microcapsules containing n-nonadecane by a melt coaxial electrospray method. J Electrostat 73:56–64

Liang WG, Yang C, Wen GQ, Wang W, Ju XJ, Xie R, Chu LY (2014) A facile and controllable method to encapsulate phase change materials with non-toxic and biocompatible chemicals. Appl Therm Eng 70:817–826

Reznik SN, Yarin AL, Zussman E, Bercovici L (2006) Evolution of a compound droplet attached to a core-shell nozzle under the action of a strong electric field. Phys Fluids 18:2101–2110

Sakuladao S, Yoovidhya T, Wongsasulak S (2011) Coaxial electrospinning and sustained release properties of gleatin-cellulose acetate core- shell ultrafine fibers. Sci Asia 37:335–343

Ahmad Z, Zhang HB, Farook U, Edirisinghe M, Stride E, Colombo P (2008) Generation of multilayered structures for biomedical applications using a novel tri-needle coaxial device and electrohydrodynamic flow. J R Soc Interface 5:1255–1261

Yu DG, Branford-White C, White K, Chatterton NP, Zhu LM, Huang LY, Wang B (2011) A modified coaxial elecrospinning for preparing fibers from a high concentration polymer solution. Express Polym Lett 5:732–741

Kim W, Kim SS (2010) Multishell encapsulation using a triple coaxial electrospray system. Anal Chem 82:4644–4647

Kim W, Kim SS (2011) Synthesis of biodegradable triple-layered capsules using a triaxial electrospray method. Polymer 52:3325–3336

Lee YH, Bai MY, Chen DR (2011) Multidrug encapsulation by coaxial tri- capillary electrospray. Colloid Surf B 82:104–110

Wu Y, Yu B, Jackson A, Zha W, Lee LJ, Wyslouzil BE (2009) Coaxial electohydrodynamic spraying: a novel one-step technique to prepare oligodeoxynucleotid encapsulated lipoplex nanoparticles. Mol Pharm 6:1371–1379

Zhang S, Kawakami K, Yamamoto M, Masaoka Y, Kataoka M, Yamashita S, Sakuma S (2011) Coaxial electrospray formulations for improving oral absorption of a poorly water- soluble drug. Mol Pharma 8:807–813

Lee YH, Mei F, Bai MY, Zhao S, Chen DR (2010) Release profile characteristics of biodegradeable polymer coated drug particles fabricated by dual capillary electrospray. J Control Release 145:58–65

Yu DG, Lu P, Zhu LM, Li XY (2010) A Novel simple electrospining process for prepareing co-axial ultrafine fibers. MACE. doi:10.1109/MACE.2010.5535266

Luo H, Huang Y, Wang D, Shi J (2013) Coaxial electrospinning as a new method to study confined crystallization of polymer. J Polym Sci Pol Phys 51:376–383

Zussman E, Yarin AL, Bazilevsky AV, Avrahami R, Feldman M (2006) Electrospun polyacrylonitrile/poly(methyl methacrylate)-derived turbostratic carbon micro/nanotubes. Adv Mater 18:348–353

Ghayempour S, Mortazavi SM (2013) Fabrication of micro-nanocapsuels by a new electrospraying method using coaxial jets and examination of effective parameters on their production. J Electrostat 71:717–727

Fabien S (2011) In: Bernardes MADS (ed) Developments in heat transfer. InTech, Rijeka

Moghadam H, Samimi M, Samimi A, Khorram M (2008) Electro-spray of high viscous liquids for producing mono-sized spherical aglinate beads. Particuology 6:271–275

Huang MJ, Eames PC, Norton B (2006) Comparison of a small-scale 3D PCM thermal control model with a validated 2D PCM thermal control model. Sol Energy Mater Sol Cells 90:1961–1972

Kumar A, Ishtiaque SM (2009) Optimisation of a textile process using taguchi method. Open Text J 2:16–28

Taguchi G, Chowdhury S, Wu Y (2005) Taguchi’s quality engineering handbook. Wiley, Somerset

Fang Y, Al-Assaf S, Phillips GO, Nishinari K, Funami T, Williams PA, Li L (2007) Multiple steps and critical behaviors of the binding of calcium to alginate. J Phys Chem 111:2456–2462

Straatmann A, Borchard W (2003) Phase separation in calcium alginate gels. Eur Biophys J 32:412–417

Chan ES, Lee BB, Ravindra P, Poncelet D (2009) Prediction models for shape and size of calcium alginate macrobeads produced through extrusion technique. J Colloid Interfce Sci 338:63–72

Chan ES (2011) Preparation of Ca-alginate beads containing high oil content: influence of process variables on encapsulation effciency and bead properties. Carbohyd Polym 84:1267–1275

Lee KY, Heo TR (2000) Survival of Bifidobacterium longum immobilized in calcium alginate beads in simulated gastric juices and bile salt solution. Appl Environ Microbiol 66:869–873

Seifert DB, Phillips JA (1997) Production of small, monodispersed alginate beads for cell immobilization. Biotechnol Prog 13:562–568

Bock N, Woodruff MA, Hutmacher DW, Dargaville TR (2011) Electrospraying, a reproducible method for production of polymeric microspheres for biomedical applications. Polymer 3:131–149

Moghe AK, Gupta B (2008) Co-aixal electrospining for nanofiber structures: preparation and applications. Polym Rev 48:353–377

Ganan-Calvo AM, Davila J, Barrero A (1997) Current and droplet size in the electrospraying of liquids. Scaling laws. J Aerosol Sci 28:249–275

Zhang H, Wang X (2009) Fabrication and performances of microcapsulated phase change materials based on n-octadecane core and resorcinol-modified melamin-fomaldehyde shell. Colloids Surf A 332:129–138

Qiu X, Li W, Song G, Chu X, Tang G (2012) Fabrication and characterization of microencapsulated n-octadecane with different crosslinked methylmethacrylate- based polymer shell. Sol Energy Mater Sol Cells 98:283–293

Sakugawa K, Sakugawa K, Ikeda A, Takemura A, Ono H (2004) Simplified method for estimation of composition of alginates by FTIR. J Appl Polym Sci 93:1372–1377

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Moghaddam, M.K., Mortazavi, S.M. & Khaymian, T. Micro/nano-encapsulation of a phase change material by coaxial electrospray method. Iran Polym J 24, 759–774 (2015). https://doi.org/10.1007/s13726-015-0364-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13726-015-0364-x