Abstract

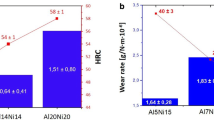

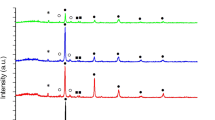

Three new high-entropy alloys of the Ni–Al–Cr–Mo–W system were produced by vacuum arc melting and assessed concerning their microstructure and sliding wear resistance. The NiAl content was kept constant at 60 at.%, and three alloys, namely NiAl–25Cr–7.5Mo–7.5W, NiAl–20Cr–10Mo–10W and NiAl–15Cr–12.5Mo–12.5W, were investigated by changing the relative ratios between Cr–Mo–W. All microstructures were found to consist of primary phases, eutectic microconstituent, a small amount of Al–Cr-based intermetallic phases and precipitated phases after spinodal decomposition. Adiabatic conditions, originated from the presence of tungsten with the highest melting point and its leading role in the initiation of solidification, were proved to affect the extent and morphology of features like the eutectic microconstituent. In particular, higher concentrations of W–Mo caused more powerful adiabatic conditions and, thus, thicker eutectic growing radially in a partitioning mode. The sliding wear response of the produced system seems to follow the classical sliding wear laws of Archard. This behaviour is further supported by multiple factors, such as the nature of the oxide phases being formed upon sliding and the integrity and rigidity of the interface between the primary and secondary phases.

Similar content being viewed by others

References

D.B. Miracle, The physical and mechanical properties of NiAl. Acta Mater. 41, 649 (1993)

P. Ferrandini, W.W. Batista, R. Caram, Influence of growth rate on the microstructure and mechanical behaviour of a nial-mo eutectic alloy. J. Alloys Compd. 381, 91–98 (2004)

J.L. Walter, H.E. Cline, The effect of solidification rate on structure and high-temperature strength of the Eutectic NiAl-Cr. Metall. Trans. 1, 1221–1229 (1970)

S. Bogner, L. Hu, S. Hollad, W. Hu, G. Gottstein, A. Bührig-Polaczek, Microstructure of a Eutectic NiAl-Mo alloy directionally solidified using an industrial scale and a laboratory scale bridgman furnace. Int. J. Mater. Res. 103, 17–23 (2012)

L. Hu, W. Hu, G. Gottstein, S. Bogner, S. Hollad, A. Bührig-Polaczek, Investigation into microstructure and mechanical properties of NiAl-Mo composites produced by directional solidification. Mater. Sci. Eng. A. 539, 211–222 (2012)

D.R. Johnson, X.F. Chen, B.F. Oliver, R.D. Noebe, J.D. Whittenberger, Directional solidification and mechanical properties of NiAl single bond NiAlTa alloys. Intermetallics. 3, 141–152 (1995)

D. Shechtman, W.J. Boettinger, T.Z. Kattamis, F.S. Biancaniello, Microstructure and phase solubility extension in rapidly solidified NiAl-Cr quasibinary eutectic. Acta Mater. 32(5), 749–756 (1984)

R.I. Barabash, W. Liu, J.Z. Tischler, H. Bei, J.D. Budai, Phase-specific elastic/plastic interface interactions in layered NiAl–Cr(Mo) structures. Acta Mater. 60, 3279 (2012)

S.T. Chen, W.Y. Tang, Y.F. Kuo, S.Y. Chen, C.H. Tsau, T.T. Shun, J.W. Yeh, Microstructure and properties of age hardenable AlxCrFe1.5MnNi0.5 alloys. Mater. Sci. Eng. A. 527(21–22), 5818–5825 (2010)

C.Y. Hsu, C.C. Juan, T.S. Sheu, S.K. Chen, J.W. Yeh, Effect of aluminum content on microstructure and mechanical properties of AlxCoCrFeMo0.5Ni high-entropy alloys. J. Met. 65, 1840–1847 (2013)

C.Y. Hsu, T.S. Sheu, J.W. Yeh, S.K. Chen, Effect of iron content on wear behavior of AlCoCrFexMo0.5Ni high-entropy alloys. Wear. 268, 653–659 (2010)

J.M. Wu, S.J. Lin, J.W. Yeh, S.K. Chen, Y.S. Huang, H.C. Chen, Adhesive wear behavior of AlxCoCrCuFeNi high-entropy alloys as a function of aluminum content. Wear. 261(5–6), 513–519 (2006)

M.H. Chuang, M.H. Tsai, W.R. Wang, S.J. Lin, J.W. Yeh, Microstructure and wear behavior of AlxCo1.5CrFeNi1.5Tiy high-entropy alloys. Acta Mater. 59, 6308–6317 (2011)

Q. Ye, B. Yang, J. Zhao, G. Yang, Z. Gong, L. Zhang, AlCoCrFeNi1.9(Mo, Nb, Hf, C) high entropy alloy strengthened by a novel long-period stacking ordered (LPSO) structure and (Nb, M)C (M = Mo, Hf, Cr). Mater. Lett. 304, 130646 (2021). https://doi.org/10.1016/j.matlet.2021.130646

P. L. J. Conway*, D. Golay, L. Bassman, M. Ferry, K. J. Laws, Thermodynamic modelling to predict phase stability in BCC + B2 Al–Ti–Co–Ni–Fe–Cr high entropy alloys, Mater. Chem. Phys. (2022) 125395, https://doi.org/10.1016/j.matchemphys.2021.125395

Z. Xu, P. Zhang*, W. Wang*, Q. Shi, H. Yang, D. Wang, Y. Hong, L. Wang, C. Guo, S. Lin, M. Dai, AlCoCrNiMo high-entropy alloy as diffusion barrier between NiAlHf coating and Ni-based single crystal superalloy, Surface Coat. Technol. 414 (2021) https://doi.org/10.1016/j.surfcoat.2021.127101

D. Liu, P. Yu, G. Li,*, P.K. Liaw, R. Liu, High-temperature high-entropy alloys AlxCo15Cr15Ni70-x based on the Al-Ni binary system, Mater. Sci. Eng. A 724 (2018) 283–288, https://doi.org/10.1016/j.msea.2018.03.058

E.S. Panina, N. Yu Yurchenko, S.V. Zherebtsov, M.A. Tikhonovsky, M.V. Mishunin, N. D. Stepanov*, Structures and mechanical properties of Ti-Nb-Cr-V-Ni-Al refractory high entropy alloys, Mater. Sci. Eng. A 786 (2020) 139409, https://doi.org/10.1016/j.msea.2020.139409

J. Joseph*, M. Senadeera, Q. Chao, K.F. Shamlaye, S. Rana, S. Gupta, S. Venkatesh, P. Hodgson, M. Barnett, D. Fabijanic, Computational design of thermally stable and precipitation-hardened Al-Co-Cr-Fe-Ni-Ti high entropy alloys, J. Alloys Compd. 888 (2021) 161496, https://doi.org/10.1016/j.jallcom.2021.161496

M. Ostrowska, P. Riani, B. Bocklund, Z.-K. Liu, G. Cacciamani, Thermodynamic modelling of the Al-Co-Cr-Fe-Ni, High Entropy Alloys supported by key experiments, J. Alloys Compound., in press, https://doi.org/10.1016/j.jallcom.2021.162722

N.D. Stepanov∗, D.G. Shaysultanov, M.A. Tikhonovsky, S.V. Zherebtsov, Structure and high temperature mechanical properties of novel nonequiatomic Fe-(Co, Mn)-Cr-Ni-Al-(Ti) high entropy alloys, Intermetallics 102 (2018) 140–151, https://doi.org/10.1016/j.intermet.2018.09.010

Z. Shang*, Q. Zhang, J. Shen, H. Bai, X. Dong, W. Bai, L. Zhong, G. Liu, Y. Xu, Effects of Nb/Ti additions and heat treatment on the microstructure evolution and hardness of as-cast and directionally solidified NiAleCr(Mo) alloy, J. Mater. Res. Technol., 2021, 10, 905-915, https://doi.org/10.1016/j.jmrt.2020.12.089

Z. Fu*, R. Koc, TiNiFeCrCoAl, high-entropy alloys as novel metallic binders for TiB2-TiC based composites, Mater. Sci. Eng. A 735 (2018) 302–309, 10.1016/j.msea.2018.08.058

C.-S. Chen*, C.-C. Yang, H.-Y. Chai, J.-W. Yeh, J. L. H. Chau, Novel cermet material ofWC/multi-element alloy, Int. J. Refract. Metals Hard Mater. 43 (2014) 200–204, https://doi.org/10.1016/j.ijrmhm.2013.11.005

B. L. Ezquerra, T.S. Biurrun, L.L. Cabezas, J.M. Sánchez Moreno*, F. I. Lopez, R. M. Pampliega, Sintering of WC hardmetals with Ni-Co-Cr-Ti-Al multi-component alloys, Int. J. Refract. Metals Hard Mater. 77 (2018) 44–53, https://doi.org/10.1016/j.ijrmhm.2018.07.007

B. Tang, D.A. Cogswell, G. Xu, S. Milenkovic, Y. Cui, Formation mechanism of eutectic microstructure in NiAl–Cr composites. Phys. Chem. Chem Phys. 18(29), 19773–19786 (2016)

D.R. Johnson, X.F. Chen, B.F. Oliver, R.D. Noebe, J.D. Whittenberger, Processing and mechanical properties of in-situ composites from the NiAl-Cr and the NiAl-(Cr, Mo) eutectic systems. Intermetallics. 3(2), 99–13 (1995). https://doi.org/10.1016/0966-9795(95)92674-O

H.E. Cline, J.L. Walter, The effect of alloy additions on the rodplate transition in the eutectic NiAl–Cr. Metall Trans. 1(10), 2907–2917 (1970)

C. Mathiou, K. Giorspyros, E. Georgatis, A.E. Karantzalis, Microstructural verification of the theoretically predicted morphologies of the NiAl-Cr pseudo-binary alloy systems and NiAl-Cr eutectic structure modification by Mo addition. SN Appl. Sci.. 1, 1292 (2019). https://doi.org/10.1007/s42452-019-1338-y

C. Mathiou, K. Girospyros, E. Georgatis, A. Poulia, A.E. Karantzalis, NiAl-Cr-Mo medium entropy alloys: microstructural verification, solidification considerations, and sliding wear response. Materials. 13(16), 3445 (2020). https://doi.org/10.3390/ma13163445

Y. Zhou, D. Zhou, X. Jin, L. Zhang, X. Du, B. Li, Design of non-equiatomic medium-entropy alloys. Sci. Rep. 8, 1236 (2018). https://doi.org/10.1038/S41598-018-19449-0

K. Bochenek, M. Basista, Advances in processing of NiAl intermetallic alloys and composites for high temperature aerospace applications. Prog. Aerosp. Sci. 79, 136–146 (2015). https://doi.org/10.1016/j.paerosci.2015.09.003

H. Bei, E.P. George, Microstructures and mechanical properties of a directionally solidified NiAl-Mo eutectic alloy. Acta Mater. 53(1), 69–77 (2005). https://doi.org/10.1016/j.actamat.2004.09.003

J.F. Zhang, J. Shen, Z. Shang, Z.R. Feng, L.S. Wang, H.Z. Fu, Microstructure and room temperature fracture toughness of directionally solidified NiAl-Mo eutectic in situ composites. Intermetallics. 21(1), 18–25 (2012). https://doi.org/10.1016/j.intermet.2011.10.002

X.F. Chen, D.R. Johnson, R.D. Noebe, B.F. Oliver, Deformation and fracture of a directionally solidified NiAl-28Cr-6Mo eutectic alloy. J. Mater. Res. 10(5), 1159–1170 (1995). https://doi.org/10.1557/JMR.1995.1159

J.D. Whittenberger, S.V. Raj, I.E. Locci, J.A. Salem, Effect of growth rate on elevated temperature plastic flow and room temperature fracture toughness of directionally solidified NiAl-31Cr-3Mo. Intermetallics. 7(10), 1159–1168 (1999). https://doi.org/10.1016/S0966-9795(99)00023-0

S.V. Raj, I.E. Locci, Microstructural characterization of a directionally-solidified Ni-33 (at.%) Al-31Cr-3Mo eutectic alloy as a function of withdrawal rate. Intermetallics. 9(3), 217–227 (2001). https://doi.org/10.1016/S0966-9795(00)00128-X

S.V. Raj, I.E. Locci, J.A. Salem, R.J. Pawlik, Effect of directionally solidified microstructures on the room-temperature fracture-toughness properties of Ni- 33(at.%)Al-33Cr-1Mo and Ni-33(at.%)Al-31Cr-3Mo eutectic alloys grown at different solidification rates. Metall. Mater. Trans. A. 33(3), 597–612 (2002). https://doi.org/10.1007/s11661-002-0122-5

Z. Shang, J. Shen, L. Wang, Y. Du, Y. Xiong, H. Fu, Investigations on the microstructure and room temperature fracture toughness of directionally solidified NiAl-Cr(Mo) eutectic alloy. Intermetallics. 57(1), 25–33 (2015). https://doi.org/10.1016/j.intermet.2014.09.012

J. Peng, P. Franke, H.J. Seifert, Experimental investigation and CALPHAD assessment of the eutectic trough in the system NiAl-Cr-Mo. J. Phase Equilib. Diffus. 37(5), 592–600 (2016). https://doi.org/10.1007/s11669-016-0490-y

Demirtas, H., Gungor, A. Effect of alloying elements on the microstructure and mechanical properties of NiAl–Cr(Mo) eutectic alloy. Int. Sci. J. Mater. Sci. Non-Equilib Phase Transform. 2015, 1(2), 25–29.

Z. Shang, J. Shen, J. Zhang, L. Wang, L. Wang, H. Fu, Effect of microstructures on the room temperature fracture toughness of NiAl–32Cr–6Mo hypereutectic alloy directionally solidified at different withdrawal rates. Mater. Sci. Eng. A. 6(11), 306–312 (2014)

L. Wang, J. Shen, Y. Zhang, H. Xu, H. Fu, Microstructure and mechanical properties of NiAl-based hypereutectic alloy obtained by liquid metal cooling and zone melted liquid metal cooling directional solidification techniques. J. Mater. Res. 31(5), 646–654 (2016). https://doi.org/10.1557/jmr.2016.61

H. Naser-Zoshki, Ali-Reza Kiani-Rashid *, Jalil Vahdati-Khaki, Design of a low density refractory high entropy alloy in non-equiatomic W-Mo–Cr–Ti–Al system. Vacuum. 181, 109614 (2020). https://doi.org/10.1016/j.vacuum.2020.109614

B.X. Cao, T. Yang, L. Fan, J.H. Luan, Z.B. Jiao, C.T. Liu*, Refractory alloying additions on the thermal stability and mechanical properties of high-entropy alloys, Mater. Sci. Eng. A 797 (2020) 140020, https://doi.org/10.1016/j.msea.2020.140020

J. Guo, Z. Wang, L. Sheng, L. Zhou, C. Yuan, Z. Chen, L. Song, Wear properties of NiAl based materials. Pro. Nat. Sci. Mater. 22(5), 414–425 (2012). https://doi.org/10.1016/j.pnsc.2012.10.008

http://www.factsage.cn/fact/phase_diagram.php?file=Mo-W.jpg&dir=SGTE

Q. Mei, J. Li, Dependence of liquid supercooling on liquid overheating levels of Al small particles. Materials. 9(7), 1–8 (2016). https://doi.org/10.3390/ma9010007

B. Yang, J.H. Perepezko, J.W.P. Schmelzer, Y. Gao, C. Schick, Dependence of crystal nucleation on prior liquid overheating by differential fast scanning calorimeter. J. Chem. Phys. (2014). https://doi.org/10.1063/1.4868002

http://www.factsage.cn/fact/phase_diagram.php?file=Cr-Mo.jpg&dir=SGTE

http://www.factsage.cn/fact/phase_diagram.php?file=Al-Cr.jpg&dir=FSlite

Prestipino, S. A maximum-entropy approach to the adiabatic freezing of a supercooled liquid, Retrieved at 02/04/2020 from: https://arxiv.org/pdf/1304.7593.pdf.

J.F. Archard, Contact and rubbing of flat surfaces. J. Appl. Phys. 24, 981–988 (1953). https://doi.org/10.1063/1.1721448

J. Glascott, F.H. Stott, G.C. Wood, The effectiveness of oxides in reducing sliding wear of alloys. Oxid. Met. 24, 99–114 (1985). https://doi.org/10.1007/BF00664227

F.H. Stott, G.C. Wood, The influence of oxides on the friction and wear of alloys. Tribol. Int. 11(4), 211–218 (1978). https://doi.org/10.1016/0301-679X(78)90178-0

L. Moravcikova-Gouvea et al., High-strength Al0.2Co1.5CrFeNi1.5Ti high-entropy alloy peoduced by powder metallurgy and casting: A comparison of microstructures, mechanical and tribological properties. Mater. Charact. 159, 110046 (2020). https://doi.org/10.1016/j.matchar.2019.110046

Funding

This research is co-financed by Greece and the European Union (European Social Fund—ESF) through the Operational Programme “Human Resources Development, Education and Lifelong Learning” in the context of the project “Strengthening Human Resources Research Potential via Doctorate Research” (MIS-5000432), implemented by the State Scholarships Foundation (ΙΚΥ).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors would like to declare no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Mathiou, C., Giorspyros, K., Georgatis, E. et al. NiAl–Cr–Mo–W High-Entropy Systems Microstructural Verification, Solidification Considerations and Sliding Wear Response. Metallogr. Microstruct. Anal. 11, 7–20 (2022). https://doi.org/10.1007/s13632-021-00816-9

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13632-021-00816-9