Abstract

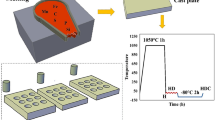

This paper analyzes how a deep cryogenic process changes the microstructure and mechanical properties of a medium-carbon low-alloy steel. The light microscopy, microhardness testing, and transmission electron microscopy reveal that η-carbide and martensite are constituent phases of deep cryogenic treated (DCT) steel, while the microstructure of conventional heat-treated (CHT) steel consists of cementite, martensite, and retained austenite. Transmission electron microscopy also shows that the particles of η-carbide have the shape of ultra-fine globules in DCT martensite. The η-carbides grow in a Hirotsu and Nagakura orientation relationship to the martensitic matrix that enables highly coherent interphase boundaries. The results of the mechanical tests, including tensile and Charpy impact tests, show that the deep cryogenic process can improve toughness in terms of elongation (~12.81%), tensile fracture energy (~266 MPa), and the ductile–brittle transition temperature (~−17.2 °C). The results of fractography are also consistent with the improvement in toughness. It is also found that the strength and macrohardness values are increased. Unlike CHT steel, discontinuous yielding is observed in DCT steel. Moreover, there is no change in Young’s modulus due to the deep cryogenic treatment.

Similar content being viewed by others

References

R.B. Scott, Cryogenic Engineering, vol. 282 (Van Nostrand, Princeton, 1959)

W. Klopp, Aerospace Structural Metals Handbook, 39th edn. (Purdue Research Foundation, West Lafayette, 1992), pp. 1–12

A. Bensely, A. Prabhakaran, D. Mohan Lal, G. Nagarajan, Enhancing the wear resistance of case carburized steel (En 353) by cryogenic treatment. Cryogenics 45, 747–754 (2005)

D. Candane, N. Alagumurthi, K. Palaniradja, Effect of cryogenic treatment on microstructure and wear characteristics of AISI M35 HSS. Int. J. Mater. Sci. Appl. 2(2), 56–65 (2013)

V. Firouzdor, E. Nejati, F. Khomamizadeh, Effect of deep cryogenic treatment on wear resistance and tool life of M2 HSS drill. J. Mater. Process. Technol. 206, 467–472 (2008)

S. Li, L. Deng, X. Wu, Y.A. Min, H. Wang, Influence of deep cryogenic treatment on microstructure and evaluation by internal friction of a tool steel. Cryogenics 50, 754–758 (2010)

F. Meng, K. Tagashira, R. Azuma, H. Sohma, Role of eta-carbide precipitations in the wear resistance improvements of Fe-12Cr-Mo-V-1.4C tool steel by cryogenic treatment,”. ISIJ Int. 34, 205–210 (1994)

D. Mohan Lal, S. Renganarayanan, A. Kalanidhi, Cryogenic treatment to augment wear resistance of tool and die steels. Cryogenics 41, 149–155 (2001)

A. Molinari, M. Pellizzari, S. Gialanella, G. Straffelini, K. Stiasny, Effect of deep cryogenic treatment on the mechanical properties of tool steels. J. Mater. Process. Technol. 118, 350–355 (2001)

A. Tyshchenko, W. Theisen, A. Oppenkowski, S. Siebert, O. Razumov, A. Skoblik et al., Low-temperature martensitic transformation and deep cryogenic treatment of a tool steel. Mater. Sci. Eng., A 527, 7027–7039 (2010)

V. Alexiades, E.C. Aifantis, Singular problems in the theory of stress-assisted diffusion. SIAM J. Math. Anal. 14, 925–933 (1983)

A. Akhbarizadeh, M. Golozar, A. Shafeie, M. Kholghy, Effects of austenizing time on wear behavior of D6 tool steel after deep cryogenic treatment. J. Iron. Steel Res. Int. 16, 29–32 (2009)

K. Amini, A. Akhbarizadeh, S. Javadpour, Investigating the effect of the quench environment on the final microstructure and wear behavior of 1.2080 tool steel after deep cryogenic heat treatment. Mater. Des. 45, 316–322 (2012)

M. Koneshlou, K. Meshinchi Asl, F. Khomamizadeh, Effect of cryogenic treatment on microstructure, mechanical and wear behaviors of AISI H13 hot work tool steel. Cryogenics 51, 55–61 (2011)

A. Oppenkowski, S. Weber, W. Theisen, Evaluation of factors influencing deep cryogenic treatment that affect the properties of tool steels. J. Mater. Process. Technol. 210, 1949–1955 (2010)

A. Hadi, MS thesis, Maleke-ashtar University of Technology, Isfahan, Iran (2014) (in Persian)

ASTM International, Iron and Steel Products, Annual Book of ASTM Standards, A370-B, 01.01 (ASTM International, West Conshohocken, 1989)

ASTM Standard E8M-04, Standard Test Methods for Tension Testing of Metallic Materials (ASTM International, West Conshohocken, 2004)

P. Baldissera, Deep cryogenic treatment of AISI 302 stainless steel: Part I—Hardness and tensile properties. Mater. Des. 31, 4725–4730 (2010)

T. Yu, J. Yang, Effect of retained austenite on GPM A30 high-speed steel. J. Mater. Eng. Perform. 16, 500–507 (2007)

M.A. Meyers, K.K. Chawla, Mechanical Behavior of Materials, vol. 547 (Cambridge University Press, Cambridge, 2009)

T. Sakaki, K. Ohnuma, K. Sugimoto, Y. Ohtakara, Plastic anisotropy of dual-phase steels. Int. J. Plast 6, 591–613 (1990)

S. Zhirafar, A. Rezaeian, M. Pugh, Effect of cryogenic treatment on the mechanical properties of 4340 steel. J. Mater. Process. Technol. 186, 298–303 (2007)

D. Senthilkumar, I. Rajendran, M. Pellizzari, J. Siiriainen, Influence of shallow and deep cryogenic treatment on the residual state of stress of 4140 steel. J. Mater. Process. Technol. 211, 396–401 (2011)

G.E. Totten, Steel Heat Treatment: Metallurgy and Technologies, vol. 1 (CRC Press, Boca Raton, 2007)

M. Sauzay, K. Vor, Influence of plastic slip localization on grain boundary stress fields and microcrack nucleation. Eng. Fract. Mech. 110, 330–349 (2013)

R. Padmanabhan, W. Wood, Precipitation of ϵ carbide in martensite. Mater. Sci. Eng. 65, 289–297 (1984)

D. Jack, K. Jack, Invited review: carbides and nitrides in steel. Mater. Sci. Eng. 11, 1–27 (1973)

A. Zare, A. Ekrami, Effect of martensite volume fraction on work hardening behavior of triple phase (TP) steels. Mater. Sci. Eng., A 528, 4422–4426 (2011)

ASM Handbook, Fractography, vol. 12 (2nd printing, 1992) (ASM International, Materials Park, 1987), p. 217

A. Zare, A. Ekrami, Influence of martensite volume fraction on tensile properties of triple phase ferrite–bainite–martensite steels. Mater. Sci. Eng., A 530, 440–445 (2011)

R.W.K. Honeycombe, H.K.D.H. Bhadeshia, Steels: Microstructure and Properties (Edward Arnold, London, 1981)

P. Novak et al., A statistical, physical-based, micro-mechanical model of hydrogen-induced intergranular fracture in steel. Mech. Phys. Solids 58, 206–226 (2010)

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Zare, A., Mansouri, H. & Hosseini, S.R. Effect of Deep Cryogenic Treatment on the Microstructure and Mechanical Properties of HY-TUF Steel. Metallogr. Microstruct. Anal. 4, 169–177 (2015). https://doi.org/10.1007/s13632-015-0206-4

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13632-015-0206-4