Abstract

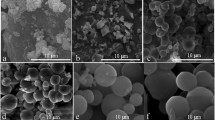

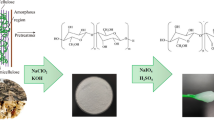

In this study, cellulose extracted from the factory waste poplar was converted into value-added carbon spheres by means of hydrothermal carbonization (HTC). Oxygen-rich functional group carbon spheres with smooth morphology, good dispersibility, controllable particle size, high carbon content, and high calorific value were prepared under various process conditions. The optimum process conditions for obtaining good shape were temperature 250 ℃, time of 12 h, and cellulose dosage of 1 g. Under these conditions, the produced carbon microspheres exhibited smooth surface, high dispersion, and uniform particles. The Fourier transform infrared spectrometer (FTIR), X-ray photoelectron spectroscopy (XPS), and elemental analyses indicated that the carbon content was as high as ~ 75% with increasing temperature and time, and the theoretically calculated higher heating values (HHV) were 29.4 MJ/kg. In addition, the H/C and O/C ratios were quite different relative to the raw materials. This demonstrates that the cellulose underwent dehydration, decarboxylation, and demethylation during hydrothermal carbonization to form carbon microspheres with oxygen-rich functional groups. Next, the carbon materials were analyzed by the porous structure of the sample (BET), thermogravimetric analyzer (TG), Raman, and X-ray diffraction (XRD), which further proved that the carbon microspheres were high-concentration aromatized amorphous non-porous carbon materials.

Similar content being viewed by others

References

Sivaranjanee R, Kumar PS (2021) A review on cleaner approach for effective separation of toxic pollutants from wastewater using carbon sphere’s as adsorbent: preparation, activation and applications. J Clean Prod 291(26):125911

Khan TA, Saud AS, Jamari SS, Rahim MA, Park JW, Kim HJ (2019) Hydrothermal carbonization of lignocellulosic biomass for carbon rich material preparation: a review. Biomass Bioenerg 130 (11): 105384.1–105384.16.

Aka B, Ksa B, Tba B (2020) Advances in design strategies for preparation of biochar based catalytic system for production of high value chemicals-ScienceDirect. Bioresour Technol 299:122564

Ramesh M, Rajeshkumar L, Bhoopathi R (2021) Carbon substrates: a review on fabrication, properties and applications. Carbon Lett 31(1):557–580

Liu WJ, Jiang H, Yu HQ (2019) Emerging applications of biochar-based materials for energy storage and conversion. Energy Environ Sci 12(6):1751–1779

Banerjee S, De B, Sinha P, Cherusseri J, Kar K (2020) Applications of supercapacitors. Handbook of Nanocomposite Supercapacitor Materials I. https://doi.org/10.1007/978-3-030-43009-2

Wang L, Ok YS, Tsang DCW et al (2020) New trends in biochar pyrolysis and modification strategies: feedstock, pyrolysis conditions, sustainability concerns and implications for soil amendment. Soil Use Manage 36:358–386. https://doi.org/10.1111/sum.12592

Saha N, Saba A, Saha P, Mc Gaughy K, Franqui-Villanueva D, Orts W, Hart-Cooper W, Reza M (2019) Hydrothermal carbonization of various paper mill sludges: an observation of solid fuel properties. Energies 12(5):858

Qu Y, Xu L, Chen Y, Sun S, Wang Y, Guo L (2021) Efficient toluene adsorption/desorption on biochar derived from in situ acid-treated sugarcane bagasse. Environ Sci Pollut R 28(44):62616–62627

Gupta N, Kumar A, Dhasmana H, Kumar A, Verma A, Shukla P, Jain VK (2021) Effect of shape and size of carbon materials on the thermophysical properties of magnesium nitrate hexahydrate for solar thermal energy storage applications. J Energy Storage 41:102899

Ikram S, Das O, Bhattacharyya D (2016) A parametric study of mechanical and flammability properties of biochar reinforced polypropylene composites. Compos Part A Appl Sci Manuf 91:177–188

Nayak S K, Nayak B, Mishra P C, Noor M M, Nanda S (2019) Effects of biodiesel blends and producer gas flow on overall performance of a turbocharged direct injection dual-fuel engine. Energ Source Part A. https://doi.org/10.1080/15567036.2019.1694101

Li Y, Xing B, Ding Y, Han X, Wang S (2020) A critical review of the production and advanced utilization of biochar via selective pyrolysis of lignocellulosic biomass. Bioresour Technol 312:123614

Berl E, Schmidt A, Koch H (1932) The development of carbon. Angew Chem 45:0517–0519

Schuhmacher J, Huntjens F, Vankrevelen D (1960) Chemical structure and properties of coal. XXVI-Studies on artificial coalification Fuel 39(3):223–234

Wang Y, Hu YJ, Hao X, Peng P, Sun RC (2020) Hydrothermal synthesis and applications of advanced carbonaceous materials from biomass: a review. Adv Compos Hybrid Ma 3:267–284

Solís MS, Arias AF (2009) The production of carbon materials by hydrothermal carbonization of cellulose. Carbon 47(9):2281–2289

Sevilla M, Fuertes A (2009) Chemical and structural properties of carbonaceous products obtained by hydrothermal carbonization of saccharides. Chem-Eur J 15:4195–4203. https://doi.org/10.1002/chem.200802097

He Q, Yu Y, Wang J, Suo X, Liu Y (2021) Kinetic study of the hydrothermal carbonization reaction of glucose and its product structures. Ind Eng Chem Res 60(12):4552–4561

Saha N, Reza MT (2021) Effect of pyrolysis on basic functional groups of hydrochars. Biomass Conversion Bior 11(4):1117–1124

Saha N, Saba A, Reza MT (2019) Effect of hydrothermal carbonization temperature on pH, dissociation constants, and acidic functional groups on hydrochar from cellulose and wood. J Anal Appl Pyrol 137(1):138–145

Zheng Q, Morimoto M, Takanohashi T (2017) Production of carbonaceous microspheres from wood sawdust by a novel hydrothermal carbonization and extraction method. Rsc Adv 7(67):42123–42128

Fg A, Lmgr A, Ow A, Etk B, As C, El A (2021) Hydrothermal conversion of different lignocellulosic biomass feedstocks–effect of the process conditions on hydrochar structures. Fuel 302(15):121166

Lester E, Avila C, Pang CH, Williams O, Perkins J, Gaddipatti S, Tucker G, Manuel Barraza J, Patricia Trujillo-Uribe M, Wu T (2018) A proposed biomass char classification system. Fuel 232(15):845–854

Athanasios D, Stella B (2017) Hydrothermal liquefaction of various biomass and waste feedstocks for biocrude production: a state of the art review. Renew Sust Energ Rev 68:113–125

Williams PT, Horne PA (1994) The role of metal salts in the pyrolysis of biomass. Renew Energ 4(1):1–13

Heidari M, Norouzi O, Salaudeen SA, Acharya B, Dutta A (2019) Prediction of hydrothermal carbonization with respect to the biomass components and severity factor. Energy Fuel 33(10):9916–9924

Zeng M, Ge Z, Ma Y, Zha Z, Zhang H (2021) On-line analysis of the correlation between gasification characteristics and microstructure of woody biowaste after hydrothermal carbonization. Bioresour Technol 342:126009

Khan TA, Kim H, Gupta A, Jamari SS, Jose R (2019) Synthesis and characterization of carbon microspheres from rubber wood by hydrothermal carbonization. J Chem Technol Biot 94(5):1374–1383

Kang S, Li X, Fan J, Chang J (2012) Characterization of hydrochars produced by hydrothermal carbonization of lignin, cellulose, d-xylose, and wood meal. Ind Eng Chem Res 51(26):9023–9031

Sibel B, Kabakc S, Seniha B (2019) Hydrothermal carbonization of various lignocellulosics: fuel characteristics of hydrochars and surface characteristics of activated hydrochars. ScienceDirect Waste Manage 100:259–268

Nakason K, Panyapinyopol B, Kanokkantapong V, Viriya-Empikul N, Kraithong W, Pavasant P (2017) Hydrothermal carbonization of oil palm pressed fiber: effect of reaction parameters on product characteristics. Int Energy J 17(2):47–56

Elaigwu SE, Greenway GM (2016) Chemical, structural and energy properties of hydrochars from microwave-assisted hydrothermal carbonization of glucose. Int J Ind Chem 7(4):449–456

Lei Y. Q, Su H, Tian R (2016) Morphology evolution, formation mechanism and adsorption properties of hydrochars prepared by hydrothermal carbonization of corn stalk. Rsc Adv 10.1039.C6RA21607B.

Zakaria M, Ani NBC, Jamari S, Ghazali S, Ali M (2016) Effect of mixing towards the production of carbonaceous Kenaf fiber via hydrothermal carbonization process. Aust J Basic Appl Sci 10(17):122–127

Shen Y (2020) A review on hydrothermal carbonization of biomass and plastic wastes to energy products. Biomass Bioenerg 134:105479

Kta C, Sk B, Sb C (2014) A review of hydrothermal biomass processing. Renew Sust Energ Rev 40:673–687

Bardhan M, Novera TM, Tabassum M, Islam MA, Islam MA, Hameed BH (2021) Co-hydrothermal carbonization of different feedstocks to hydrochar as potential energy for the future world: a review. J Cleaner Prod 298:126734

Kim D, Y oshikawa, Kunio, Park, Young K, (2015) Characteristics of biochar obtained by hydrothermal carbonization of cellulose for renewable energy. Energies 8(12):14040–14048

Leng L, Yang L, Leng S, Zhang W, Li H (2021) A review on nitrogen transformation in hydrochar during hydrothermal carbonization of biomass containing nitrogen. Sci Total Environ 765:143679

Wu Q, Li W, Liu S (2014) Carboxyl-rich carbon microspheres prepared from pentosan with high adsorption capacity for heavy metal ions. Mater Res Bull 60:516–523

Khan N, Mohan S, Dinesha P (2021) Regimes of hydrochar yield from hydrothermal degradation of various lignocellulosic biomass a review. J Cleaner Prod 288:125629

Yu S, Yang X, Zhao P, Li Q, Zhou H, Zhang Y (2022) From biomass to hydrochar: evolution on elemental composition, morphology, and chemical structure. J Energy Inst 101:194–200

Wang C, Huang S, Zhu Y, Zhang S (2022) Comparative study on the characteristics of hydrothermal products from lignocellulosic wastes. J Anal Appl Pyrolysis 161:105408

Wang TF, Zhai YB, Zhu Y, Li CT, Zeng GM (2018) A review of the hydrothermal carbonization of biomass waste for hydrochar formation: process conditions, fundamentals, and physicochemical properties. Renew Sust Energ Rev 90:223–247

Sheng K, Zhang S, Liu J, Shuang E, Zhang X (2019) Hydrothermal carbonization of cellulose and xylan into hydrochars and application on glucose isomerization. J Clean Prod 237:117831

Xie ZL, White RJ, Weber J, Taubert A, Titirici MM (2011) Hierarchical porous carbonaceous materials via ionothermal carbonization of carbohydrates. J Mater Chem 21(20):7434–7434

Lu X, Jiang C, Hu Y, Zhong H, Liu H (2018) Preparation of hierarchically porous carbon spheres by hydrothermal carbonization process for high-performance electrochemical capacitors. J of Appl Electrochem 48(1):233–241

Liu S, Zhao Y, Zhang B, Xia H, Zhou J, Xie W, Li H (2018) Nano-micro carbon spheres anchored on porous carbon derived from dual-biomass as high rate performance supercapacitor electrodes. J Power Sources 381(31):116–126

Román S, Ledesma B, Álvarez A, Coronella C, Qaramaleki SV (2020) Suitability of hydrothermal carbonization to convert water hyacinth to added-value products. Renewable Energy 146:1649–1658

Nicolae SA, Au H, Modugno P, Luo H, Szego AE, Qiao M, Titirici MM (2020) Recent advances in hydrothermal carbonisation: from tailored carbon materials and biochemicals to applications and bioenergy. Green Chem 22(15):4747–4800

Ahmed Khan T, Kim HJ, Gupta A, Jamari SS, Jose R (2019) Synthesis and characterization of carbon microspheres from rubber wood by hydrothermal carbonization. J Chem Technol Biotechnol 94(5):1374–1383

Kang S, Li X, Fan J, Chang J (2012) Characterization of hydrochars produced by hydrothermal carbonization of lignin, cellulose, D-xylose, and wood meal. Ind Eng Chem Res 51:9023–9031

Funding

This work was support from the Science and Technology Plan Projects of Inner Mongolia Autonomous Region of China (No. 2021GG0074), Inner Mongolia Autonomous Region graduate Research and Innovation Funding project (No. B20191134Z), Key scientific research project of Inner Mongolia Autonomous Region Higher Education Science and technology Research (No. NJZZ21065).

Author information

Authors and Affiliations

Contributions

Sufen Hao: Overall data collection, analysis of data, and writing. Qian Zhang and Yanfeng Shi: Final compilation of data and design of all figures and tables. Qiang Guo and Pingping Li: Overall modification of manuscript in terms of language, spelling, and decided the way of representation. Jintian Huang: Reviewing and editing the manuscript. All authors read and approved the final manuscript.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no competing interests.

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Hao, S., Zhang, Q., Shi, Y. et al. Preparation and characterization of the poplar micro-nano cellulose sustainable carbon spheres. Biomass Conv. Bioref. 14, 9581–9594 (2024). https://doi.org/10.1007/s13399-022-03003-0

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13399-022-03003-0