Abstract

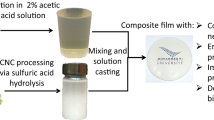

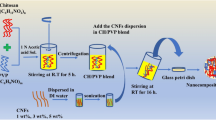

This work reports for the first time the development and characterization of ҡ-carrageenan-based bio-nanocomposite films incorporated with cellulose nanocrystals (CNC) derived from Indian gooseberry pomace, a major waste from fruits and vegetables processing industry. The CNCs were incorporated in different proportions, viz., 1, 3, 5, and 7%, and solution casting method was used to prepare the films. The effect of CNC loading on the structural, morphological, mechanical, and barrier properties was evaluated. Compared with the control films, CNC-reinforced bio-nanocomposite films showed better barrier and mechanical properties. After 5% CNC loading, water vapor permeability of the films decreased from 3.21 to 2.36 g mm/m2 day kPa while an increase in the tensile strength from 23.28 to 39.75 MPa was seen. FTIR analysis showed that no structural changes took place in the polymeric matrix after the addition of CNC, while FESEM results showed that higher CNC loadings (7%) lead to agglomeration. Crystallinity of the films increased with the addition of CNC, as evident from XRD. The developed bio-nanocomposite films have the potential to be utilized for high-barrier food packaging applications.

Similar content being viewed by others

References

Kumar A, Gupta V, Gaikwad KK (2021) Microfibrillated cellulose from pine cone: extraction, properties, and characterization. Biomass Convers Biorefinery 1–8. https://doi.org/10.1007/s13399-021-01794-2

Cazón P, Velazquez G, Ram\’\irez JA, Vázquez M (2017) Polysaccharide-based films and coatings for food packaging: a review. Food Hydrocoll 68:136–148

Calva-Estrada SJ, Jiménez-Fernández M, Lugo-Cervantes E (2019) Protein-based films: advances in the development of biomaterials applicable to food packaging. Food Eng Rev 11:78–92

Mohamed SAA, El-Sakhawy M, El-Sakhawy MA-M (2020) Polysaccharides, protein and lipid-based natural edible films in food packaging: a review. Carbohydr Polym 238:116178

Sanchez-Garcia MD, Lopez-Rubio A, Lagaron JM (2010) Natural micro and nanobiocomposites with enhanced barrier properties and novel functionalities for food biopackaging applications. Trends Food Sci & Technol 21:528–536

Grishkewich N, Mohammed N, Tang J, Tam KC (2017) Recent advances in the application of cellulose nanocrystals. Curr Opin Colloid \& Interface Sci 29:32–45

Šturcová A, Davies GR, Eichhorn SJ (2005) Elastic modulus and stress-transfer properties of tunicate cellulose whiskers. Biomacromolecules 6:1055–1061

Mariano M, El Kissi N, Dufresne A (2014) Cellulose nanocrystals and related nanocomposites: Review of some properties and challenges. J Polym Sci Part B Polym Phys 52:791–806

Singh S, Gaikwad KK, Park S-I, Lee YS (2017) Microwave-assisted step reduced extraction of seaweed (Gelidiella aceroso) cellulose nanocrystals. Int J Biol Macromol 99:506–510

El Miri N, Abdelouahdi K, Barakat A et al (2015) Bio-nanocomposite films reinforced with cellulose nanocrystals: rheology of film-forming solutions, transparency, water vapor barrier and tensile properties of films. Carbohydr Polym 129:156–167

Singh S, Gaikwad KK, Lee YS (2018) Antimicrobial and antioxidant properties of polyvinyl alcohol bio composite films containing seaweed extracted cellulose nano-crystal and basil leaves extract. Int J Biol Macromol 107:1879–1887

Perumal AB, Sellamuthu PS, Nambiar RB, Sadiku ER (2018) Development of polyvinyl alcohol/chitosan bio-nanocomposite films reinforced with cellulose nanocrystals isolated from rice straw. Appl Surf Sci 449:591–602

Li H, Shi H, He Y et al (2020) Preparation and characterization of carboxymethyl cellulose-based composite films reinforced by cellulose nanocrystals derived from pea hull waste for food packaging applications. Int J Biol Macromol 164:4104–4112

Tecante A, del Santiago MCN (2012) Solution properties of $κ$-carrageenan and its interaction with other polysaccharides in aqueous media. Rheology 1:241–264

Necas J, Bartosikova L (2013) Carrageenan: a review. Vet Med (Praha) 58

Rhein-Knudsen N, Meyer AS (2021) Chemistry, gelation, and enzymatic modification of seaweed food hydrocolloids. Trends Food Sci \& Technol

Piculell L (2006) Gelling carrageenans. Food polysaccharides their Appl 239

Blakemore WR, Harpell AR, others (2010) Carrageenan. Food stabilisers, Thick gelling agents:73–94

Al-Baarri AN, Legowo AM, Rizqiati H, et al (2018) Application of iota and kappa carrageenans to traditional several food using modified cassava flour. In: IOP Conference Series: Earth and Environmental Science. p 12056

Nouri A, Yaraki MT, Ghorbanpour M, Wang S (2018) Biodegradable $κ$-carrageenan/nanoclay nanocomposite films containing Rosmarinus officinalis L. extract for improved strength and antibacterial performance. Int J Biol Macromol 115:227–235

Shojaee-Aliabadi S, Mohammadifar MA, Hosseini H et al (2014) Characterization of nanobiocomposite kappa-carrageenan film with Zataria multiflora essential oil and nanoclay. Int J Biol Macromol 69:282–289

Wahab IF, Abd Razak SI (2016) Bionanocomposite fim of kappa-carrageenan/nanotube clay: growth of hydroxyl apatite and model drug release. Dig J Nanomater Biostruct 11:963–972

Popescu M-C, Dogaru B-I, Sun D et al (2019) Structural and sorption properties of bio-nanocomposite films based on $κ$-carrageenan and cellulose nanocrystals. Int J Biol Macromol 135:462–471

Gupta V, Ramakanth D, Verma C et al (2021) Isolation and characterization of cellulose nanocrystals from amla (Phyllanthus emblica) pomace. Biomass Convers Biorefinery:1–12. https://doi.org/10.1007/s13399-021-01852-9

Khan A, Khan RA, Salmieri S et al (2012) Mechanical and barrier properties of nanocrystalline cellulose reinforced chitosan based nanocomposite films. Carbohydr Polym 90:1601–1608

Slavutsky AM, Bertuzzi MA (2014) Water barrier properties of starch films reinforced with cellulose nanocrystals obtained from sugarcane bagasse. Carbohydr Polym 110:53–61

Azeredo HMC, Mattoso LHC, Avena-Bustillos RJ et al (2010) Nanocellulose reinforced chitosan composite films as affected by nanofiller loading and plasticizer content. J Food Sci 75:N1–N7

Chaichi M, Hashemi M, Badii F, Mohammadi A (2017) Preparation and characterization of a novel bionanocomposite edible film based on pectin and crystalline nanocellulose. Carbohydr Polym 157:167–175

Reddy KO, Guduri BR, Rajulu AV (2009) Structural characterization and tensile properties of borassus fruit fibers. J Appl Polym Sci 114:603–611

Haafiz MKM, Hassan A, Zakaria Z, Inuwa IM (2014) Isolation and characterization of cellulose nanowhiskers from oil palm biomass microcrystalline cellulose. Carbohydr Polym 103:119–125

cSen M, Erboz EN (2010) Determination of critical gelation conditions of $κ$-carrageenan by viscosimetric and FT-IR analyses. Food Res Int 43:1361–1364

Mujtaba M, Salaberria AM, Andres MA et al (2017) Utilization of flax (Linum usitatissimum) cellulose nanocrystals as reinforcing material for chitosan films. Int J Biol Macromol 104:944–952

Distantina S, Fahrurrozi M, others (2013) Synthesis of hydrogel film based on carrageenan extracted from Kappaphycus alvarezii. Mod Appl Sci 7:22

Vasconcelos NF, Feitosa JPA, da Gama FMP et al (2017) Bacterial cellulose nanocrystals produced under different hydrolysis conditions: properties and morphological features. Carbohydr Polym 155:425–431

Wang LF, Rhim JW (2015) Preparation and application of agar/alginate/collagen ternary blend functional food packaging films. Int J Biol Macromol 80:460–468. https://doi.org/10.1016/j.ijbiomac.2015.07.007

Doh H, Whiteside WS (2020) Isolation of cellulose nanocrystals from brown seaweed, Sargassum fluitans, for development of alginate nanocomposite film. Polym Cryst 3:e10133

Oun AA, Rhim J-W (2016) Isolation of cellulose nanocrystals from grain straws and their use for the preparation of carboxymethyl cellulose-based nanocomposite films. Carbohydr Polym 150:187–200

Kassab Z, Aziz F, Hannache H et al (2019) Improved mechanical properties of k-carrageenan-based nanocomposite films reinforced with cellulose nanocrystals. Int J Biol Macromol 123:1248–1256

Yadav M, Chiu F-C (2019) Cellulose nanocrystals reinforced $κ$-carrageenan based UV resistant transparent bionanocomposite films for sustainable packaging applications. Carbohydr Polym 211:181–194

Gaikwad KK, Lee JY, Lee YS (2016) Development of polyvinyl alcohol and apple pomace bio-composite film with antioxidant properties for active food packaging application. J Food Sci Technol 53:1608–1619. https://doi.org/10.1007/S13197-015-2104-9

Gaikwad KK, Singh S, Negi YS, Lee YS (2020) The effect of trans-polyisoprene/LDPE based active films on oxidative stability in roasted peanuts. J Food Meas Charact 14:1857–1864. https://doi.org/10.1007/s11694-020-00433-0

Kadam AA, Singh S, Gaikwad KK (2021) Chitosan based antioxidant films incorporated with pine needles (Cedrus deodara) extract for active food packaging applications. Food Control 124:107877. https://doi.org/10.1016/J.FOODCONT.2021.107877

Kumar A, Gupta V, Singh S, Saini S, Gaikwad KK (2021c) Pine needles lignocellulosic ethylene scavenging paper impregnated with nanozeolite for active packaging applications. Ind Crops Prod 170:113752. https://doi.org/10.1016/j.indcrop.2021.113752

Kumar J, Akhila K, Gaikwad KK (2021d) Recent developments in intelligent packaging systems for food processing industry: A review Journal of Food Processing & Technology 12:895

Ramakanth D, Singh S, Maji PK, Lee YS, Gaikwad KK (2021) Advanced packaging for distribution and storage of COVID-19 vaccines: a review. Environ Chem Lett 19:3597–3608. https://doi.org/10.1007/s10311-021-01256-1

Singh G, Singh S, Kumar B, Gaikwad KK (2021a) Active barrier chitosan films containing gallic acid based oxygen scavenger. J Food Meas Charact 15:585–593. https://doi.org/10.1007/s11694-020-00669-w

Singh AK, Ramakanth D, Kumar A, Lee Y. S, Gaikwad KK (2021b) Active packaging technologies for clean label food products: a review. J Food Meas Charact 15:4314-4324. 10.1007/s11694- 021-01024-3

Singh S, Maji PK, Lee YS, Gaikwad KK (2021c) Applications of gaseous chlorine dioxide for antimicrobial food packaging: a review. Environmental Chemistry Letters 19:253–270. https://doi.org/10.1007/s10311-020-01085-8

Tanwar R, Gupta V, Kumar P, Kumar A, Singh S, Gaikwad KK (2021) Development and characterization of PVA-starch incorporated with coconut shell extract and sepiolite clay as an antioxidant film for active food packaging applications. Int J Biol Macromol 185:451–461. https://doi.org/10.1016/j.ijbiomac.2021.06.179

Acknowledgment

Author K. K. Gaikwad would like to sincerely thank the Department of Science and Technology (DST), Government of India, for the financial support provided under DST INSPIRE Faculty (DST/INSPIRE/04/2018/002544).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that there are no conflicts of interest.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Gupta, V., Yadav, R., Tanwar, R. et al. ҡ-Carrageenan-based bio-nanocomposite film reinforced with cellulose nanocrystals derived from amla pomace for food packaging. Biomass Conv. Bioref. 13, 16899–16908 (2023). https://doi.org/10.1007/s13399-021-02028-1

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13399-021-02028-1