Abstract

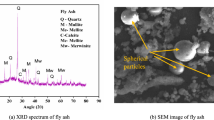

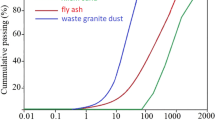

In this research, the performance of fly ash/GGBS geopolymer mortars made with different quarry waste powder as filler materials by substituting the fine recycled aggregate (RS) with different ratios. Also, it was evaluated based on mechanical, physical, freeze–thaw, and microstructural analysis. Limestone waste (L), marble waste (M), and basalt waste powder (B) were used as filler materials developing eco-friendly and economical geopolymer from industrial waste as a promising sustainable area of research. Strength properties, ultrasonic pulse velocity, physical properties, freeze–thaw, XRD, and SEM analysis of geopolymer samples were investigated. The results revealed that using waste filler materials together with recycled aggregate effectively improves the mechanical properties of geopolymer composites substituting three different filling materials affected water absorption positively, strength properties, and freeze–thaw results. Current findings point to a potential solution. Successful use of fly ash, slag, recycled aggregate, and quarry waste has been achieved. The output of the study is expected to result in effective and environmentally friendly management of recycled wastes.

Similar content being viewed by others

References

Benhelal, E.; Zahedi, G.; Shamsaei, E.; Bahadori, A.: Global strategies and potentials to curb CO2 emissions in cement industry. J. Clean. Prod. 51, 142–161 (2013). https://doi.org/10.1016/j.jclepro.2012.10.049

VanDeventer, J.S.J.; JohnProvis, L.; Duxson, P.: Technical and commercial progress in the adoption of geopolymer. cem. Miner. Eng. 29, 89–104 (2012). https://doi.org/10.1016/j.mineng.2011.09.009

Ma, C.-K.; Zawawi Awang, A.; Omar, W.: Structural and material performance of geopolymer concrete: a review. Constr. Build. Mater. 186, 90–102 (2018). https://doi.org/10.1016/j.conbuildmat.2018.07.111

Ziada, M.; Tammam, Y.; Erdem, S.; Lezcano, R.A.G.: Investigation of the mechanical, microstructure and 3D fractal analysis of nanocalcite-modified environmentally friendly and sustainable cementitious composites. Buildings 12(1), 36 (2022). https://doi.org/10.3390/buildings12010036

PatrickMaier, L.; StephanDurham, A.: Beneficial use of recycled materials in concrete mixtures. Constr. Build. Mater. 29, 428–437 (2012). https://doi.org/10.1016/j.conbuildmat.2011.10.024

Tran, V.Q.; Dang, V.Q.; Ho, LSi.: Evaluating compressive strength of concrete made with recycled concrete aggregates using machine learning approach. Constr. Build. Mater. 323, 126578 (2022). https://doi.org/10.1016/j.conbuildmat.2022.126578

Sunita, Effect of biomass Ash, foundry sand and recycled concrete aggregate over the strength aspects of the concrete, Materials Today: Proceedings 50 Part 5 2022 2044–2051 https://doi.org/10.1016/j.matpr.2021.09.405.

Şahin, F.; Uysal, M.; Canpolat, O.; Aygörmez, Y.; Cosgun, T.; Dehghanpour, H.: Effect of basalt fiber on metakaolin-based geopolymer mortars containing rilem, basalt and recycled waste concrete aggregates. Constr. Build. Mater. 301, 124113 (2021). https://doi.org/10.1016/j.conbuildmat.2021.124113

Zhang, N., et al.: On the incorporation of class f fly-ash to enhance the geopolymerization effects and splitting tensile strength of the gold mine tailings-based geopolymer. Constr. Build. Mater. 308, 125112 (2021). https://doi.org/10.1016/j.conbuildmat.2021.125112

Zhang, N.; Hedayat, A.; Sosa, H.G.; Tupa, N.; Morales, I.Y.; Loza, R.S.: Crack evolution in the Brazilian disks of the mine tailings-based geopolymers measured from digital image correlations: an experimental investigation considering the effects of class F fly ash additions. Ceram. Int. 47(22), 32382–32396 (2021)

Zhou, W.; Shi, X.; Lu, X.; Qi, C.; Luan, B.; Liu, F.: The mechanical and microstructural properties of refuse mudstone-GGBS-red mud based geopolymer composites made with sand. Constr. Build. Mater. 253, 119193 (2020). https://doi.org/10.1016/j.conbuildmat.2020.119193

Koshy, N.; Dondrob, K.; Hu, L.; Wen, Q.; Meegoda, J.N.: Synthesis and characterization of geopolymers derived from coal gangue, fly ash and red mud. Constr. Build. Mater. 206, 287–296 (2019). https://doi.org/10.1016/j.conbuildmat.2019.02.076

Chakkor, O.; Altan, M.F.; Canpolat, O.: Elevated temperature, freezing-thawing and mechanical properties of limestone, marble, and basalt powders reinforced metakaolin-red mud-based geopolymer mortars. Iran. J. Sci. Technol. Trans. Civ. Eng. (2022). https://doi.org/10.1007/s40996-021-00797-3

Shahrour, N.; Allouzi, R.: Shear behavior of captive- and short- column effects using different basalt aggregate contents. J. Build. Eng. 32, 101508 (2020). https://doi.org/10.1016/j.jobe.2020.101508

Binici, H.; Yardim, Y.; Aksogan, O.; Resatoglu, R.; Dincer, A.; Karrpuz, A.: Durability properties of concretes made with sand and cement size basalt. Sustain. Mater. Technol. 23, 00145 (2020). https://doi.org/10.1016/j.susmat.2019.e00145

Premkumar, R.; Hariharan, P.; Rajesh, S.: Effect of silica fume and recycled concrete aggregate on the mechanical properties of GGBS based geopolymer concrete. Mater. Today. Proc. (2022). https://doi.org/10.1016/j.matpr.2021.12.442

Şahin, F.; Uysal, M.; Canpolat, O.: Systematic evaluation of the aggregate types and properties on metakaolin based geopolymer composites. Constr. Build. Mater. 278, 122414 (2021). https://doi.org/10.1016/j.conbuildmat.2021.122414

Venyite, P.; Makone, E.C.; Kaze, R.C., et al.: Effect of combined metakaolin and basalt powder additions to laterite-based geopolymers activated by rice husk ash (RHA)/NaOH solution. SILICON 14, 1643–1662 (2022). https://doi.org/10.1007/s12633-021-00950-7

Ghorbani, S.; Mohammadi-Khatami, M.; Ghorbani, S.; Elmi, A.; Farzan, M.; Soleimani, V.; Negahban, M.; Tam, V.W.; Tavakkolizadeh, M.: Effect of magnetized water on the fresh, hardened and durability properties of mortar mixes with marble waste dust as partial replacement of cement. Constr. Build. Mater. 267, 121049 (2021)

Tekin, I.: Properties of NaOH activated geopolymer with marble, travertine and volcanic tuff wastes. Constr. Build. Mater. 127, 607–617 (2016). https://doi.org/10.1016/j.conbuildmat.2016.10.038

Khyaliya, R.K.; Kabeer, K.S.; Vyas, A.K.: Evaluation of strength and durability of lean mortar mixes containing marble waste. Constr. Build. Mater. 147, 598–607 (2017)

Khodabakhshian, A.; Ghalehnovi, M.; De Brito, J.; Shamsabadi, E.A.: Durability performance of structural concrete containing silica fume and marble industry waste powder. J. clean. produc. 170, 42–60 (2018)

Lim, Y.Y.; Pham, T.M.; Kumar, J.: Sustainable alkali activated concrete with fly ash and waste marble aggregates: Strength and Durability studies. Constr. Build. Mater. 283, 122795 (2021)

Pedro Perez-Cortes, J.: Ivan escalante-garcia, alkali activated metakaolin with high limestone contents – Statistical modeling of strength and environmental and cost analyses. Cement Concr. Compos. 106, 103450 (2020). https://doi.org/10.1016/j.cemconcomp.2019.103450

Morsy, M.S.; Rashad, A.M.; Shoukry, H.; Mokhtar, M.M.: Potential use of limestone in metakaolin-based geopolymer activated with H3PO4 for thermal insulation. Constr. Build. Mater. 229, 117088 (2019)

Jiang, Q.; Mu, S.: Study on influence of limestone powder on the fresh and hardened properties of early age metakaolin based geopolymer. RILEM Bookseries. 10, 253–259 (2015). https://doi.org/10.1007/978-94-017-9939-3_31

Cwirzen, A.; Provis, J.L.; Penttala, V.; Habermehl-Cwirzen, K.: The effect of limestone on sodium hydroxide-activated metakaolin-based geopolymers. Constr. Build. Mater. 66, 53–62 (2014). https://doi.org/10.1016/j.conbuildmat.2014.05.022

Rakhimova, N.R.; Rakhimov, R.Z.; Naumkina, N.I.; Khuzin, A.F.; Osin, Y.N.: Influence of limestone content, fineness, and composition on the properties and microstructure of alkali-activated slag cement. Cem. Concr. Compos. 72, 268–274 (2016)

Aggregates for concrete, TS EN-706, 2009

Standard test method for compressive strength of hydraulic cement mortars, ASTM C109/C109M, 2021

Standard test method for flexural strength of hydraulic-cement mortars, ASTM C348–20, 2020

Standard test method for splitting tensile strength of cylindrical concrete specimens, ASTM C-496, 2017

Standard Test Method for Measurement of Rate of Absorption of Water by Hydraulic-Cement Concretes, ASTM C1585–20, 2020

NgwemBayiha, B.; Billong, N.; Yamb, E.; Cyriaque Kaze, R.; Nzengwa, R.: Effect of limestone dosages on some properties of geopolymer from thermally activated halloysite. Constr. Build. Mater. 217, 28–35 (2019). https://doi.org/10.1016/j.conbuildmat.2019.05.058

Sardinha, M.; de Brito, J.; Rodrigues, R.: Durability properties of structural concrete containing very fine aggregates of marble sludge. Constr. Build. Mater. 119, 45–52 (2016). https://doi.org/10.1016/j.conbuildmat.2016.05.071

Wang, D.; Shi, C.; Farzadnia, N.; Shi, Z.; Jia, H.; Zhihua, Ou.: A review on use of limestone powder in cement-based materials: mechanism, hydration and microstructures. Constr. Build. Mater. 181, 659–672 (2018). https://doi.org/10.1016/j.conbuildmat.2018.06.075

Kore, S.D.; Vyas, A.K.: Impact of marble waste as coarse aggregate on properties of lean cement concrete. Case. Stud. Constr. Mater. 4, 85–92 (2016)

Vardhan, K.; Siddique, R.; Goyal, S.: Strength, permeation and micro-structural characteristics of concrete incorporating waste marble. Constr. Build. Mater. 203, 45–55 (2019). https://doi.org/10.1016/j.conbuildmat.2019.01.079

Tammam, Y.; Uysal, M.; Canpolat, O.: Effects of alternative ecological fillers on the mechanical, durability, and microstructure of fly ash-based geopolymer mortar. Eur. J. Environ. Civ. Eng. (2021). https://doi.org/10.1080/19648189.2021.1925157

Bayiha, B.N.; Billong, N.; Yamb, E.; Kaze, R.C.; Nzengwa, R.: Effect of limestone dosages on some properties of geopolymer from thermally activated halloysite. Constr. Build. Mater. 217, 28–35 (2019). https://doi.org/10.1016/j.conbuildmat.2019.05.058

Embong, R.; Kusbiantoro, A.; Shafiq, N.; Nuruddin, M.F.: Strength and microstructural properties of fly ash based geopolymer concrete containing high-calcium and water-absorptive aggregate. J. Clean. Product. 112(1), 816–822 (2016). https://doi.org/10.1016/j.jclepro.2015.06.058

Colangelo, F.; Roviello, G.; Ricciotti, L.; Ferrándiz-Mas, V.; Messina, F.; Ferone, C.; Tarallo, O.; Cioffi, R.; Cheeseman, C.R.: Mechanical and thermal properties of lightweight geopolymer composites. Cement. Concr. Compos. 86, 266–272 (2018). https://doi.org/10.1016/j.cemconcomp.2017.11.016

Pilehvar, S.; Szczotok, A.M.; FranciscoRodríguez, J.; Valentini, L.; Lanzón, M.; Pamies, R.; Kjøniksen, A.-L.: Effect of freeze-thaw cycles on the mechanical behavior of geopolymer concrete and Portland cement concrete containing micro-encapsulated phase change materials. Constr. Build. Mater. 00, 94–103 (2019). https://doi.org/10.1016/j.conbuildmat.2018.12.057

Allahverdi, A.; Abadi, M.M.; Hossain, K.M.; Lachemi, M.: Resistance of chemically-activated high phosphorous slag content cement against freeze–thaw cycles. Cold. Reg. Sci. Technol. 103, 107–114 (2014)

Aygörmez, Y.; Canpolat, O.; Al-mashhadani, M.M.; Uysal, M.: Elevated temperature, freezing-thawing and wetting-drying effects on polypropylene fiber reinforced metakaolin based geopolymer composites. Constr. Build. Mater. 235, 117502 (2020). https://doi.org/10.1016/j.conbuildmat.2019.117502

Al-mashhadani, M.M.; Canpolat, O.: Effect of various NaOH molarities and various filling materials on the behavior of fly ash based geopolymer composites. Constr. Build. Mater. 262, 120560 (2020). https://doi.org/10.1016/j.conbuildmat.2020.120560

Provis, J.L.; Lukey, G.C.; van Deventer, J.S.J.: Do geopolymers actually contain nanocrystalline zeolites? a reexamination of existing results. Chem. Mater. 17(12), 3075–3085 (2005). https://doi.org/10.1021/cm050230i

Uysal, M.; Al-mashhadani, M.M.; Aygörmez, Y.; Canpolat, O.: Effect of using colemanite waste and silica fume as partial replacement on the performance of metakaolin-based geopolymer mortars. Constr. Build. Mater. 176, 271–282 (2018). https://doi.org/10.1016/j.conbuildmat.2018.05.034

Zhang, Y.J.; Li, S.; Wang, Y.C.; Xu, D.L.: Microstructural and strength evolutions of geopolymer composite reinforced by resin exposed to elevated temperature. J. Non. Cryst. Solids. 358(3), 620–624 (2012). https://doi.org/10.1016/j.jnoncrysol.2011.11.006

Wang, D.; Shi, C.; Farzadnia, N.; Shi, Z.; Jia, H.; Ou, Z.: A review on use of limestone powder in cement-based materials: mechanism, hydration and microstructures. Constr. Build. Mater. 181, 659–672 (2018). https://doi.org/10.1016/j.conbuildmat.2018.06.075

Valcuende, M.; Parra, C.; Marco, E.; Garrido, A.; Martínez, E.; Cánoves, J.: Influence of limestone filler and viscosity-modifying admixture on the porous structure of self-compacting concrete. Constr. Build. Mater. 28(1), 122–128 (2012). https://doi.org/10.1016/j.conbuildmat.2011.07.029

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

Springer Nature or its licensor holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Tammam, Y., Uysal, M., Canpolat, O. et al. Effect of Waste Filler Materials and Recycled Waste Aggregates on the Production of Geopolymer Composites. Arab J Sci Eng 48, 4823–4840 (2023). https://doi.org/10.1007/s13369-022-07230-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13369-022-07230-5