Abstract

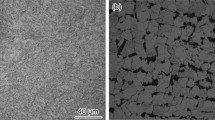

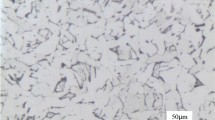

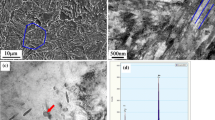

Multi-component thermal fluid flooding is an efficient thermal technology for heavy oil recovery. However, the oil and gas transported by the gathering pipeline exhibit the large temperature difference along with high O2, H2S and CO2 contents, which may easily bring serious corrosion problems to the pipeline. In this article, the present work aims to study corrosion behavior and corrosion mechanisms in a CO2/H2S/O2 coexistence system using a Huning 4 block gathering pipeline material, particularly clarifying the influence of temperature on the corrosion behavior and localized corrosion mechanism. The high-temperature autoclave was used to simulate the corrosion environments. The corrosion products at various temperatures were examined via three-dimensional optical microscopy, scanning electron microscopy, X-ray diffraction, and X-ray photoelectron spectroscopy. The maximum uniform corrosion rate of L245NS is 0.5149 mm/a (at 333 K), and the maximum local corrosion rate is 4.6258 mm/a (at 363 K). At lower temperatures (303–333 K), the corrosion product film possessed a double-layered membrane, where the bottom layer was enriched with S-based elements, mainly FeS or FeS2 and the upper layer was mainly covered by FeCO3 with the uniform corrosion state. Applying the higher temperatures (363–393 K) made the FeCO3 grain coverage more continuous and dense, leading to the formation of a dense double-layered film, where the uniform corrosion was suppressed, while localized corrosion emerged. The thermodynamics shows that an increase in the temperature was found to decrease the solubility product coefficient of FeS and FeCO3, inducing the appearance of a protective layer and inhibiting the corrosion process.

Similar content being viewed by others

Data Availability

All datasets underlying the conclusions of the paper should be available to readers. We deposit their datasets in publicly available repositories in the manuscript.

References

Sun, X.F.; Song, Z.Y.; Cai, L.F.; Zhang, Y.Y.; Li, P.: Phase behavior of heavy oil-solvent mixture systems under reservoir conditions. Pet. Sci. 17(06), 1683–1698 (2020)

Jing, J.Q.; Wang, S.; Xiao, F.; Zhang, M.; Li, H.; Guo, X.H.: Analysis of influence factors of start-up yield stress for heavy oil emulsions. Petrol. Sci. Technol. 37(11), 1–9 (2019)

Euthymios, V.; Anthony, R.K.: Doctrines and realities in viscous and heavy-oil reservoir engineering. J. Petrol. Sci. Eng. 178(6), 1164–1177 (2019)

Liu, Y.G.; Yang, H.L.; Zhao, L.C.; Sun, Y.T.;, Cui, G.; Zhao, M.G.; Hu, S.B.; Zhong, L.G.: Improve offshore heavy oil recovery by compound stimulation technology involved thermal, gas and chemical methods. In: Proceedings of 2010 Offshore Technology Conference, Houston, TX, USA (2010)

Sun, F.R.; Yao, Y.D.; Li, X.F.; Li, G.Z.; Han, S.; Qing, L.; Liu, W.Y.: Type curve analysis of multi-phase flow of multi-component thermal fluid in toe-point injection horizontal wells considering phase change. J. Petrol. Sci. Eng. 165(6), 557–566 (2018)

Hu, S.B.; Guo, L.L.; Liu, Y.J.: The effects of multi-component thermal fluids on the viscosity of offshore heavy oil. Pet. Sci. Technol. 32(20), 2458–2465 (2014)

Sun, C.B.: Corrosion factors of single-layer insulation pipeline in Bohai Oil & Gas Field. Oil Gas Storage Transp. 39(12), 1416–1421 (2020)

Zhang, J.; Xue, Y.H.; Ding, Y.; Zan, L.F.; Yang, J.; Gong, J.; Li, X.P.: Optimization method of pipeline inspection period considering corrosion defects. China Petrol. Mach. 48(5), 107–113 (2020)

Liu, X.H.; Zhang, F.Y.; Huang, K.; Cui, D.Y.; Huang, Y.H.; Miu, F.F.: Discussion about the thermal recovery of NB35-2 offshore heavy oilfield. Reservoir Eval. Dev. 1(1), 61–63 (2011)

Liu, D.; Zhao, C.M.; Su, Y.C.; Li, Y.P.; Zhang, F.Y.; Huang, Y.H.: New research and application of high efficient development technology for offshore heavy oil in China. In: Offshore Technology Conference. Houston, Texas, USA (2010)

Zhong, X.K.; Wang, Y.R.; Liang, J.J.; Chen, L.; Song, X.Q.: The coupling effect of o2 and h2s on the corrosion of g20 steel in a simulating environment of flue gas injection in the Xinjiang oil field. Materials 11(9), 1635 (2018)

Sun, J.B.; Sun, C.; Zhang, G.A.; Li, X.D.; Zhao, W.M.; Jiang, T.; Liu, H.F.; Cheng, X.K.; Wang, Y.: Effect of O2 and H2S impurities on the corrosion behavior of X65 steel in water-saturated supercritical CO2 system. Corros. Sci. 107, 31–40 (2016)

Sun, C.; Sun, J.B.; Wang, Y.; Lin, X.Q.; Li, X.D.; Cheng, X.K.; Liu, H.F.: Synergistic effect of O2, H2S and SO2 impurities on the corrosion behavior of X65 steel in water-saturated supercritical CO2 system. Corros Sci. 107(6), 193–203 (2016)

Liao, K.X.; Zhou, F.L.; Song, X.Q.; Wang, Y.R.; Zhao, S.; Liang, J.J.; Chen, L.; He, G.X.: Synergistic effect of O2 and H2S on the corrosion behavior of N80 steel in a simulated high-pressure flue gas injection system. J. Mater. Eng. Perform. 29, 155–166 (2020)

Liu, Y.; Wang, Z.H.; Li, J.X.: Fluorocarbon coating provides corrosion protection in oilfield flooding system. Mater. Performance 55, 40–44 (2016)

Clarke, S.G.: The use of inhibitors (with special reference to antimony) in the selective removal of metallic coatings and rust. J. Electrochem. Soc. 69, 131–144 (1936)

Jin, P.; Bota, G.; Robbins, W.; Nešić, S.: Analysis of oxide scales formed in the naphthenic acid corrosion of carbon steel. Energy Fuel. 30, 6853–6862 (2016)

Dong, B.J.; Zeng, D.Z.; Yu, Z.M.; Zhang, H.X.; Yu, H.Y.; Tian, G.; Yi, Y.G.: Role of polyacrylamide concentration on corrosion behavior of N80 steel in the HPAM/H2S/CO2 environment. Mater. Corros. 71(10), 526–536 (2020)

Wang, Z.H.; Zhang, L.; Yu, T.Y.; Xu, M.M.: Study of corrosion behavior of oil gathering facilities with CO2 flooding in low-permeability oilfields. Chem. Technol. Fuels Oils 53(6), 933–942 (2018)

Rosli, R.; Choi, Y.S.; Nesic, S.; Yong, D.: Corrosion of UNS G10180 steel in supercritical and subcritical CO2 with O2 as a contaminant. Corrosion 2016, Houston, Texas: NACE (2016)

Li, Y.J.; Li, X.M.; Song, W.W.; Xiong, X.M.; Ge, J.: Analysis on the influencing factors of corrosion rate of l245m steel in CO2-containing water produced from oil fields. Contemp. Chem .Ind. 47(10), 2011–2014 (2018)

Li, D.M.; Long, W.; Zou, N.: Corrosion behavior of p110ss anti-sulfer pipeline steel in low h2s and high CO2 partial pressure environment of ultradeep well. Surf. Technol.ogy 7, 102–108 (2016)

Zhu, M.; Yu, Y.; Zhang, H.H.: Corrosion behavior of L245 steel in simulated oilfield produced water at different temperatures. J. Chin. Soc. Corros. Protect. 37(3), 300–304 (2017)

Song, X.Q.; Wang, Y.R.; Liang, J.J.; Chen, L.; Zhou, F.L.; Wang, X.Y.; Liu, L.: Corrosion behavior of 35 CrMo steel under O2, H2S and CO2 mixed system. Natural Gas Oil 36(6), 92–98 (2018)

Song, X.Q.; Wang, X.Y.; Wang, Y.R.: Influence law of O2 partial pressure on the corrosion behaviors of 316L stainless steel under O2–H2S-CO2 condition. Mater. Prot. 52(8), 61–68 (2019)

Sun, C.; Wang, Y.; Sun, J.B.; Lin, X.Q.; Li, X.D.; Liu, H.F.; Cheng, X.K.: Effect of impurities on the corrosion of water-saturated supercritical CO2 transport pipeline of X65 steel. J. Supercritical Fluids 116, 70–82 (2016)

Li, J.L.; Zhu, S.D.; Qu, Z.T.; Yin, Z.F.; Lu, Y.B.; Liu, L.: Study on corrosion influencing factors of J55 casing steel. Corros. Sci. Prot. Technol. 26(1), 60–64 (2014)

Wei, L.; Pang, X.L.; Liu, C.; Gao, K.W.: Formation mechanism and protective property of corrosion product scale on X70 steel under supercritical CO2 environment. Corros. Sci. 100, 404–420 (2015)

Peisert, H.; Chassé, T.; Streubel, P.; Meisel, A.; Szargan, R.: Relaxation energies in XPS and XAES of solid sulfur compounds. J. Electron Spectrosc. Relat. Phenom. 68(5), 321–328 (1994)

Zeng, D.Z.; Yu, Z.M.; Dong, B.J.; Zhang, H.X.; Yu, H.Y.; Tian, G.; Yi, Y.G.: Investigation of service life and corrosion mechanism of tubing in production well on polymer flooding. Corros. Eng. Sci. Technol. 55(7), 634–644 (2020)

Fierro, G.; Ingo, G.M.; Mancia, F.: XPS Investigation on the corrosion behavior of 13Cr martensitic stainless steel in CO2–-H2S–-Cl environments. Corrosion -Houston Tx 45(10), 814–823 (1989)

Yin, Z.F.; Zhao, W.Z.; Bai, Z.Q.; Feng, Y.R.; Zhou, W.J.: Corrosion behavior of SM 80SS tube steel in stimulant solution containing H2S and CO2. Electrochim. Acta 53(10), 3690–3700 (2008)

Liu, H.T.; Sun, Y.T.; Ma, Z.H.; Wang, S.H.; Lin, T.; Sun, Y.B.: Research on corrosion and protection of P110 steel in high temperature CO2/O2 system. Drill. Prod. Technol. 36(1), 85–87 (2013)

Khan, M.I.; Yasmin, T.: Erosion–corrosion of low carbon (AISI 1008 Steel) ring gasket under dynamic high-pressure CO2 environment. J. Fail. Anal. Prev. 14(4), 537–548 (2014)

Ding, J.H.; Zhang, L.; Lu, M.X., et al.: The electrochemical behaviour of 316L austenitic stainless steel in Cl- containing environment under different H2S partial pressures. Appl. Surf. Sci. 289, 33–41 (2014)

Sun, W.; Nesic, S.; Woollam, R.C.: The effect of temperature and ionic strength on iron carbonate (FeCO3) solubility limit. Corros. Sci. 51(6), 1273–1276 (2009)

Sun, W.; Srdjan, N.; Young, D.: Equilibrium expressions related to the solubility of the sour corrosion product mackinawite. Ind. Eng. Chem. Res. 47(5), 1738–1742 (2008)

Yan, W.; Deng, J.G.; Dong, X.L.; Zhang, C.Y.; Li, L.H.; Li, X.R.: Corrosion products and behavior of tubing steel in CO2/H2S environment. Corrosion Prot. 32(03), 193–196 (2011)

Chen, C.F.; Hou, J.G.; Chang, W.: The influence of environmental factors on the uniform corrosion rate of CO2 and the establishment of a corrosion rate prediction model. China Offshore Oil Gas 5, 51–55 (2004)

Hou B.S. High temperature and high pressure CO2/O2 corrosion and electrochemical behavior of N80 steel. Huazhong University of Science and Technology (2017)

Lin, H.; Xu, J.; Xing, X.S.; Fan, B.T.; Yang, J.; Wang, X.P.: Corrosion behavior of L80 tubing steel in CO2/H2S environment. Surf. Technol. 45(5), 84–90 (2016)

Acknowledgements

This work was supported by the National Natural Science Foundation of China (Grant No. 51674212).

Author information

Authors and Affiliations

Contributions

The thesis was written by Shuai Zhao. The experiments and analytical method were designed by Kexi Liao. The experimental part was implemented by Feilong Zhou, The data processing was performed by Jihui Leng. The manuscript was revised by Qiang Huang and Guoxi He.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that there is no conflict of interest.

Rights and permissions

About this article

Cite this article

Zhao, S., Liao, K., Zhou, F. et al. Effect of Temperature on the Corrosion Behavior of L245NS Steel in a CO2/H2S/O2 Multi-component Thermal Fluid Collection and Transportation System. Arab J Sci Eng 47, 11223–11237 (2022). https://doi.org/10.1007/s13369-021-05906-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13369-021-05906-y