Abstract

This work proposes a Value Stream Mapping (VSM) to be used in manufacturing industry that combines Lean, Energy and Six-Sigma methodologies. Lean's VSM tool is amended to energy VSM so that the value-added and non-value-added approach can be used to determine the energy use and waste. In order to identify the maximum rejection or rework at a workstation, an entropy-based mathematical model is developed and a Lean-Energy-Six Sigma Value Stream Mapping (LESSVSM) is presented. The model can be used in manufacturing at product level where temperature and energy can be measured from input to output. The model has been implemented on a manufacturing system containing four workstations. The proposed LESSVSM model will help to industry to become more sustainable as it can minimize energy and waste in the case of rework and rejection. This study presents a systematic approach which researchers and practitioners can apply for sustainable manufacturing.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

The industrialization has increased the prosperity of civilization, but it has also raised several environmental concerns. One is the absorption of electricity. Energy efficiency pressures extend to businesses which are increasingly involved in the climate. The researchers have therefore studied methods and means in order to construct an energy-efficient machine or to reduce the energy consumption in current methods. In the ongoing research studies, the methods for addressing lean and green growth are integrated. The new energy stream mapping method has been developed with the addition of energy components as EVSM (Energy Value Stream Mapping) to VSM (Value Stream Mapping).The EVSM determines the energy consumption and waste in every phase and thus creates opportunities for energy saving. For diagnostic, energy budgeting, and economical purposes, the EVSM model can be used.

Even though EVSM helps in minimizing non value-added energy consumption, it’s not sufficient to achieve a more sustainable manufacturing which requires reduction of waste in terms of entropy. This is the motivation behind the current work to incorporate entropy besides energy.

In this work, Lean, Energy, and Six-Sigma (LESS) approaches are combined to come up with a LESS model. An entropy-based energy equation is also developed. The equation helps to identify the stations where attention is required for determining the energy of rejection and energy at rework. This equation helps to take optimal decisions in the sustainability process. In order to develop a model utilizing the entropy equation, it is considered that the product manufacturing requires four processes (i.e. four workstations). It is shown with figures in Sects. 3 and 5. In this manufacturing process, raw materials (angles) undergo first through straightening process, in which bend or distortion present in raw materials is removed. After this, angles undergo CNC, in which punching, stamping & cutting operations are performed. After CNC, notching is performed on the angles and then all products undergo galvanization. In galvanization, a protective coating of zinc is applied on the angles and cleats. Here manufacturing process is completed and all the products are sent for packaging. Each process will lead to an increase in the temperature of the work-piece, which increases the entropy of both the work-piece and the universe. It is assumed that rework and rejection at any point in the system will lead to an increase in entropy of the universe and this can be identified by the proposed Lean Energy Six Sigma VSM (LESSVSM) model.

Besides the development of the sustainable LESSVSM model, this article discusses the application of the model in a case study with a manufacturing system comprising four workstations. There does not exist enough studies in the literature showing stepwise details of the use of energy and entropy for sustainable manufacturing systems in industries. The present work is an attempt to make contribution in this regard. The LESSVSM model minimizes waste and helps towards sustainability.

The article is organized as follows. Next section covers literature review related to Value Stream Mapping, Energy Value Stream Mapping, Lean, and Six Sigma. Section 3 explains Lean, Energy, and Six Sigma model for an example product from the industry. Section 4 presents the new entropy based mathematical model for Lean, Energy, and Six Sigma Value Stream Mapping. Section 5 illustrates the model implementation. Section 6 discusses the results. Section 7 describes the conclusions and recommendations.

2 Literature Review

This section discusses the literature review related to Lean, Six Sigma, Lean Six Sigma, Value Stream Mapping (VSM) and Energy VSM.

2.1 Lean, Six Sigma and Lean Six Sigma

Lean technique emphasizes waste elimination [8, 53] and reduction of flow time between process steps [9]. Six Sigma methodology emphasizes process optimization by reducing variation [4, 18, 47]. Because Lean and Six Sigma both are process improvement techniques and have similarity in their goals and procedures, these are also combined as Lean Six Sigma methodology [43, 47]. Lean Six Sigma (LSS) tools address the waste generated during the process, identify and eliminate the non-value added activities, and reduce process variations [32]. A variety of studies have been done to study the impact of these LSS tools in manufacturing and service industries as well as non-profit organizations. Edgeman and Dugan [21] have discussed the use of Six Sigma in military and defence applications as well as pertaining to society and environment.

The effect of Lean tools like 5S, value stream mapping (VSM), Total productive maintenance, and Six Sigma tools like DMAIC (Define, Measure, Analyze, Improve, and Control) has been studied in a die manufacturing industry [51]. A Lean tool: observation is used to eliminate waste and identify causes of variations [7]. DMAIC approach has been used to improve productivity in a caravan manufacturing company in the UAE [30]. A study has been done on the existing Six Sigma methodologies and quality improvement procedures in a small engineering firm in the USA, which suggested a plan to improve service quality and customer satisfaction [10]. A modified version of DMAIC has been applied to decrease defects produced in an automotive part manufacturing company in India [36]. DMAIC approach is utilized in sheet metal forming process of deep drawing to minimize defects [1]. DMAIC has been adopted in textile industry of Bangladesh to decrease defects in denim fabric manufacturing [44]. A framework using analytic hierarchy process (AHP) and DMAIC to improve supply chain performance of manufacturing companies has been proposed [41]. A Lean and sustainability principle is applied to determine the performance of manufacturing sustainability in an Indonesian furniture industry [27]. Similarly Lean concepts are used to design a facility layout for a cylinder liner production line in China [55]. The designed layout increased the production efficiency. Six Sigma approach is also applied in a semiconductor company that used to produce cartridges for printers [48]. It helped to decrease defects in the manufacturing process.

DMAIC is applied in a UAE telecom company to improve customer satisfaction by decreasing the response time to customer requirements [43]. Pareto chart, cause and effect diagram, Kaizen, 5S, etc. are used to improve the business process of an interior design company located in the middle-east region [31]. LSS is also applied to improve service process in a higher education institution [35]. The authors also discussed the challenges faced while working with the intangible factors. The intangible impacts of LSS are analysed and reported that LSS can foster organizational innovation [2]. A review on the application of Lean, Six Sigma, or LSS initiatives in the food industry has been conducted [17] and concluded that these initiatives would decrease cost and imporve productivity. DMAIC methodology is applied in a business entity in Croatia to decrease delivery times of products in order to be competitive in the global market [39]. An investigation has been done if Lean and SS principles can be applied in public housing authorities in the USA. With a case study, it showed that these concepts can improve an affordable housing process [33].

A systematic review of literature on the application of Six Sigma approach in healthcare is presented in [5]. This work can be used as a guide in improving the quality of healthcare. An ILL (Innovativeness, Learning and Lean) index is devised to evaluate and improve healthcare organizations [19]. Identification of key factors has been done that are tied with successful continuous improvement in hospitals while implementing quality improvement methodologies such as Lean-Kaizen, SS, LSS. [25]. Lean technique is utilized to identify waste in a hospital emergency department to decrease patient length of stay [40]. Lean healthcare principles are adopted to devise an operating room effectiveness indicator, which can measure the performance and identify waste in hospital operating rooms [46]. The adaptation of this indicator in a university hospital in Brazil resulted in an increase in the operating room efficiency. DMAIC is also used in a healthcare setting for patient surge planning due to the COVID-19 pandemic [12].

2.2 Value Stream Mapping (VSM) and Energy VSM

A Lean incipience spiral model is proposed as a Lean transformation framework to be used in small and medium enterprises (SMEs) [16]. SMEs can sustain this transformation as it is guided by value stream mapping (VSM). In VSM, time for value-added and non-value-added activities are shown. VSM has been used to address problems like rejections, inventories, waiting time, setup time in a die manufacturing industry [51], where a decrease in wastage and an increase in productivity was achieved. VSM has also been applied in a simulated manufacturing company in an academic setting [3]. Adding energy consumption to value stream makes it energy value stream, which can be used to address the wastage of energy in any process chain of a manufacturing system [22]. This visual display of energy waste helps the planner to manage efficiently. But the idea of added value and non-value consumption does not propose a way to compute the time and energy input simultaneously, which in turn contributes to a concept of energy loss due to non-value added activities. To avoid this, Muller et al. [37] in their energy VSM (EVSM), evaluated time and energy inputs simultaneously to optimize value-streams including the transportation processes which are essential parts of supply chains. The incorporation of transport into energy VSM demonstrates the impact of prolonging lead time as a way of adding value to energy consumption [20]. When the output cycle is analysed, it reveals that during the full cycle there is a trend of energy consumption depending on the state of the machine. Installation, set-up, idle, and processing or production status are various states of the machine or system corresponding to different power levels [11]. This EVSM approach allows for an analysis of energy consumption during non-value-added work. The energy audit records the power level for each state [11]. It discusses the thematic state of the system and assigns energy level. Every state has its own value-added energy and non-value-added energy. When the device is set, it communicates the consumption of energy and its control.

The VSM is also effectively utilized in the process of planning to visualize and reduce waste [38]. The current state of the use of energy value stream mapping (EVSM) has been described in [52]. The waiting time is eliminated by Kanban (pull system). Verma & Sharma [50] used EVSM to address the non-productive energy consuming processes and to focus on achieving Green Manufacturing. The energy estimation is based on Lean modelling as value added and non-value added in order to holistically maximise value sources. This definition uses simulation to construct a dynamic VSM, which allows more complex systems than conventional VSMs to be analysed. This allows the Lean coordinator to envision the outcomes in an easily understandable language [50]. Value stream mappings can be updated in a table to make the teams compatible [45]. The paper shows the inability to thoroughly and adequately address industrial needs of "existing methods to manufacturing calculation, control, and energy efficiency improvement" [45]. The absence of effective instruments to recognize energy use and the ways to enhance energy effectiveness has created a gap between literature and industrial needs [14].

Pioneering stream mapping strategies have been proposed to improve energy efficiency in small and medium-sized manufacturing sectors [49]. Potential scenarios for exploring potential changes are also developed via Bayesian networks. Not only can the proposed model be used for diagnosis, but also for energy budgeting and saving measures. In view of the machinery's state energy use, visualization of the energy usage has been considered as important [29]. The total energy consumption of the company is taken into account in an integrated energy stream mapping. The process box identifies energy consumption in different production steps, but the energy wastes are linked to the non-value-added activity of the traditional VSM. In the value-added activity could be hidden energy non-value-added step, which is not considered. The focus is on the factory level, not on the product level [13]. Energy Value Stream Mapping (EVSM) as a method for determining energy consumption during any phase of development is also explored in [15] in the development of bio diesel. The first approach that maps the sustainable value stream and accounts for the energy consumption for two direct and indirect categorizations is presented in [23]. Direct energy for supporting operations and auxiliary equipment is divided into theoretical energy and auxiliary energy. For all products is then calculated the embodied energy as the sum of theoretical, auxiliary, and indirect energy consumption. EVSM is used to determine energy wastage in an auto body paint shop of an automobile manufacturing company [42].

VSM is presented in combination with energy loss equations and heat energy rate analysis to reduce energy loss in a power plant [6]. Environmental VSM is used in lean manufacturing work at Volvo [34]. DMAIC-based methodology is proposed to use sustainable VSM for sustainable manufacturing [28]. The terminology of Green Lean Six Sigma for sustainable VSM is adopted in [24]. An operational entropy model of operation-logistics systems in order to determine the operational efficiency has been developed and used in a case study in [54].

It is evident from the literature that sustainable VSM utilizing energy and entropy is a growing field for researchers and practitioners. However, there are no enough studies showing how to use sustainable VSM in sustainable manufacturing systems. The present research is an attempt to fill this gap. This work employs the concepts of Lean, Energy, and Six Sigma and presents a model that includes entropy. The model will help minimize waste and aid towards sustainability.

3 Lean Energy Six Sigma Model

Figure 1 displays the proposed Lean Energy Six Sigma (LESS) model. Starting with the application of the lean energy, all waste including energy is then applied to the system. Six-sigma instruments are then used to refine the process and reduce uncertainty, eliminating energy usage during the product life cycle. The model is named LESS (Lean, Energy, Six-Sigma) by the application of the tools in the system to achieve sustainability.

3.1 Value Stream Mapping (VSM)

Galvanized angles and cleats having holes stamp and notch are the products that are being manufactured from input (i.e. angles) by four processes. Raw materials (angles) undergo first through straightening process, in which bend or distortion present in raw materials is removed. After this, angles undergo CNC, in which punching, stamping & cutting operations are performed. After CNC, notching is performed on the angles and then all products undergo galvanization. In galvanization, a protective coating of zinc is applied on the angles and cleats. Here manufacturing process is completed and all the products are sent for packaging. Figure 2 shows the process flow diagram of the product used for the creation of the model and Fig. 3 shows its present value stream mapping (VSM).

The information which is collected from the current VSM is: Machine name, Energy (E), Cycle time (CT), Change over time (C/O), Number of workers engaged, the calculation is being made for a cycle time of each operation. For each operation, data are collected for five consecutive cycle and average data are considered for VSM. It is observed that the cycle time of the galvanization process deviates too much from the takt time of 39 s, hence the bottleneck exists here in Fig. 4. Packaging is not a part of the manufacturing process, rather it is a part of the supply chain. Packaging is done to provide products to the customers safely. Hence, Fig. 4 does not show packaging. By successful implementation of the new LESSVSM model as proposed in Sect. 5 and shown in Fig. 7, the bottlenecking can be minimized.

3.2 Energy Value Stream Mapping (EVSM)

The energy value stream mapping (EVSM) is created by taking into account the energy usage for each time-related value-added (VA) and non-value-added (NVA) activities. The relevant data are collected on the basis of each operation and the corresponding value is summarized in Table 1 and EVSM is shown in Fig. 5. Comparing energy NVA (ENVA) with the corresponding energy VA (EVA), it’s clear that the notching consumes the highest proportion of ENVA compared to its corresponding EVA. The values shown in Fig. 5 are obtained from the time study and motion study of manufacturing processes and the values of EVA and ENVA shown in Table 1 are obtained by energy calculation for the four processes. Packaging was not shown in Fig. 4 as explained in Sect. 3.1.

VSM (Fig. 4) displays takt time and provides information related to different processes, inventories etc. But EVSM (Fig. 5) consists of all information of VSM as well as represents energy consumption for value added & non value added activities i.e. EVA & ENVA.

3.3 LESS Model

Six Sigma is the data-based approach that improves process capabilities and increases the performance of process and decreases the variation. Six Sigma’s DMAIC tool is used in the current work. A concise description of all the phases of DMAIC: Define, Measure, Analyze, Improve, and Control [30] is presented here.

-

1.

Define:—In this phase various problems and complications associated with manufacturing process such as waste, rejection & rework due to energy consumption and dissipation are identified. This phase provides information about all process parameters such as inputs and outputs of manufacturing processes, suppliers and customers.

-

2.

Measure:—Information gained from the define phase helps to measure process parameters and collect data. In this phase, a Lean tool: value stream mapping (VSM) can be used. For the present production shown in Fig. 2, the corresponding VSM is displayed in Fig. 3 and explained in Sect. 3.1.

-

3.

Analyze:—In the ‘analyze’ phase, energy consumed in value-added (EVA) and non-value-added (ENVA) activities have been determined as discussed in Sect. 3.2, and EVSM has been shown in Fig. 5. This provides a great information about energy consumption in value added tasks such as manufacturing operations and energy dissipation due to non-value added tasks such as rejection.

-

4.

Improve:—Energy dissipation that occurs due to rejection and rework can be reduced by minimizing rejection and rework rates (%). Entropy based mathematical model is proposed for this phase which helps to identify rejection and rework % by using energy and entropy concepts. The detailed discussion is given in Sect. 4.

-

5.

Control:—This phase deals with physical behaviour of the proposed model i.e. whether this model sustains a real manufacturing environment or not. Hence the entropy based model is implemented on the current production with the four manufacturing processes. This has been explained in Sect. 5.

Since this work deals with integrating Lean thinking and energy savings in manufacturing processes through the Six Sigma tool, the proposed model is named as “LESS” model.

4 Entropy Based Mathematical Model For Lean Energy Six Sigma Value Stream Mapping (LESSVSM)

The next step is to minimize process variability and defects after the energy waste is minimized by eliminating the non-value added energy shown earlier in EVSM. A mathematical model based on system entropy is built to define the mechanism where maximum rejection and rework occur. The following assumptions have been made to develop this mathematical model:

-

1.

Six sigma’s DMAIC methodology is followed strictly.

-

2.

Manufacturing process is considered as an isolated system.

-

3.

Rejection and rework increase entropy of the system.

-

4.

Temperature values for each process can be measured.

-

5.

Energy consumption values for rejection and rework can be determined.

Let,

Utilizing the heat energy and work done equations for the steady-state equation as proposed by [26]

The work done at different stages can be represented as

where \({\text{Q}}_{{0\left( {{\text{MF}}} \right)}} = {\text{m}}_{{\text{i}}} \times {\text{C}}_{{\text{p}}} \times \left( {{\text{T}}_{1} - {\text{T}}_{2} } \right)\)

Let \(\mathop \sum \limits_{{\text{i}}} {\text{Q}}_{{{\text{ME}}}} = {\text{E}}_{{\text{i}}}\) and neglecting the enthalpy of material and residue.

5 Implementation of the LESSVSM Model

Consider the same product with the manufacturing processes as shown in Fig. 2. This manufacturing system has four processes or workstations between inlet and outlet as shown in Fig. 6. It is assumed that each process in the system will lead to an increase of entropy of both the work-piece and the universe. Any rework or rejection at any point in the system will cause the entropy of the system to increase further.

Let, the temperature of inlet material is T1 and the temperature of the outlet material is T2.

Let,

The total energy consumed in the system can be written as equation 9

Assuming ENVA has been taken care of by EVSM, there will be four idealistic conditions.

Condition-1: when there is no rejection or rework,

Condition-2: When there is rework(s) at one and more workstation for one or more workpiece

Condition-3: When a workpiece is being rejected at one or more workstation

Condition-4: When there are rework and then rejection or rejection and then rework at one or more workstations,

Converting (13), (17), (21), (25) in matrix form

From the matrix, the values of all the unknowns (m, r) can be calculated. The matrix can be solved using MATLAB.

From Fig. 5: E1 = 2.991 Kwh; E2 = 2.25 Kwh; E3 = 2.365 Kwh; E4 = 25.7 Kwh

Total no. of components per day = 700 piece/day =30 piece/hr.

Now from case study mass and temperature are:

mo = 20 kg, m1 = 19 kg, m2 = 18 kg, m3 = 17 kg, m4 = 15 kg,

T1 = 270 = 300K, T2 = 1270 = 400K

TA = 520 = 325K, TB = 730= 346K, TC = 970 = 370K,

Cp = 0.49 KJ/kgK

Percentage of rework = (.09744/700) = 0.0139 %

Percentage of rejection = (.050291/700) = 0.0071 %

The workstation where the highest rework and rejection occur is workstation 4. Based on the information generated from the model, EVSM is modified to LESSVSM and is shown in Fig. 7. This is the most effective tool for the industry as this value stream mapping will address, in totality the wastage in any system, and make it the most effective towards sustainability.

6 Results and Discussion

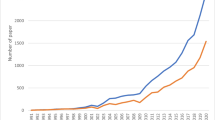

In this research work lean thinking is integrated to optimize amount of rejection & rework by utilizing energy consumption in particular workstation. The energy consumption for both value added (EVA) & non value added (ENVA) is shown in Fig. 8, which can be identified and calculated by implementing EVSM (Fig. 5).

Figure 8 gives a summary of essential information regarding energy consumption. It can be observed that galvanization process is the highest energy consuming workstation including both EVA & ENVA. It is also observed that the galvanization has higher EVA value than that of ENVA while the other three processes (workstations) have lesser EVA than ENVA. ENVA is the energy that is wasted or do not add any value i.e. energy wasted due to rejection of products. It indicates that EVA of galvanization also includes energy consumed for rework of materials, which significantly add values on products but increases production cost and lead time, also causes obstacle for a continuous and smooth production flow.

The percentage of rework and rejection is 0.0139% and 0.0071%, respectively, which is calculated from the proposed entropy based LESSVSM model. The amount of rejection and rework is very less i.e. less than 1%, this indicates that the successful implementation of the entropy based mathematical model for LESSVSM reduces amount of rejection and rework which are waste. Also reduction in amount of waste reduces energy consumption. Another benefit of this model is that with the help of this percentage, one can calculate the number of rework or rejected products that will be produced in a month or a year. So by this percentage industry will be able to calculate the cost of rework or rejected products and will include in the manufacturing cost of products to avoid any losses incurred due to the rework or rejected products.

The present work is in agreement with the work of [24, 28, and 34]. All these studies used sustainable VSM to make manufacturing systems lean and sustainable. This work differs from the work of [6] which used energy and enthalpy to reduce energy loss in a power plant. It also differs from the work reported in [54] in the sense that they used entropy in operation-logistics systems to find the operational efficiency.

The application of LESSVSM in the case study presented in this article suggest that LESSVSM can be used in industry to achieve sustainable manufacturing with process improvement, cost reduction, energy savings, and minimizing waste. With proper modification according to the type of process, type of product, type of defects, etc., this LESSVSM model can be implemented in any industry.

7 Conclusions and Recommendations

To remain sustainable, industries must make optimal decisions regarding the manufacturing costs of products. The present research work proposes a systematic approach towards making an industry sustainable by reducing waste. The model developed is validated using the information collected from a manufacturing industry for the example product shown in Fig. 2 and Fig. 6 consisting of four workstations. The authors have modified the value stream mapping (VSM) of Fig. 3 and energy VSM of Fig. 5, and have proposed a new value stream mapping: LESSVSM in Fig. 7, which is more versatile. EVSM embraces energy for value-added and non-value-added activities in each workstation for critical assessment and evaluation. The new LESSVSM model can be used to map the value stream (lean tool: VSM), energy stream (EVSM), and entropy equations. This model can be used to eliminate waste in terms of non-value added energy consumption and entropy, which helps towards sustainability.

In the present work, a step by step approach for the proposed sustainable model LESSVSM has been summarized. LESSVSM helps in the calculation of energy consumption and energy losses in each workstation. The results show that the number of rework or rejected product not only increases the cost of production but is also a burden to the society in terms of energy and waste (in case of rejection). Further, the results show that the energy used during phase 2 and 4 or the energy used in a refurbishment and rejection phase contributes to a rise in production costs. Therefore, the company would have to decide on the energy used in the reprocessing or rejection process or reduce the rate of number of rework or rejected products to reduce production costs. This model will help to increase the efficiency of the workstation (i.e. machine).

As discussed in the literature review section, sustainable VSM is an emerging research area. However, there are no enough studies in the literature showing how to apply sustainable VSM. The current study with entropy-based LESSVSM is an attempt to fill this gap. Because the model helps towards sustainability, it can be also called as Green Lean Six Sigma model. This work has presented a stepwise approach which researchers and practitioners can apply for sustainable manufacturing.

7.1 Recommendations for Future Study

-

Extension of entropy energy model to medium and large-scale industries.

-

Worldwide researchers have woken up to the productive use of energy stream analysis. Green Lean Six Sigma has a lot to do in the future.

-

Future research should concentrate on a broader use of the Green Lean VSM instrument in multiple case studies for further validation for SMEs from other industrial sectors.

-

To find new directions in their sustainable business practice strategies to achieve balance of environmental and economic objectives.

References

Al Theeb, N.A.; Hayajneh, M.T.: Six Sigma framework methodology for deep drawing process improvement. Int. J. Prod. Qual. Manag. 25(1), 18–40 (2018)

Alblooshi, M.; Shamsuzzaman, M.: Investigating the relationship between Lean Six Sigma’s intangible impacts and organisational innovation climate factors. Int. J. Prod. Perform. Manag. 69(6), 1247–1270 (2020)

Al-Odeh, M.; McLeod, A.; Badar, M.A.: Value stream mapping: recreating an industrial environment in an educational setting. Technol. Interf. Int. J. 15(2), 22–31 (2015)

Andersson, R.; Eriksson, H.; Torstensson, H.: Similarities and differences between TQM, six sigma and lean. TQM Magaz. 18(3), 282–296 (2006)

Antony, J.; Palsuk, P.; Gupta, S.; Mishra, D.; Barach, P.: Six Sigma in healthcare: a systematic review of the literature. Int. J. Qual. Reliab. Manag. 35(5), 1075–1092 (2018)

Arifin, W.I.; Vanany, I.: Energy loss analysis using value stream mapping (VSM): a power plant case study. In: International Conference on Technologies and Policies in Electric Power & Energy, Yogyakarta, Indonesia, Oct 21–22, pp. 1–5, (2019). https://doi.org/10.1109/IEEECONF48524.2019.9102541

Arumugam, V.; Antony, J.; Douglas, A.: Observation: a Lean tool for improving the effectiveness of Lean Six Sigma. The TQM Journal 24(3), 275–287 (2012)

Badar, M.A.: Lean manufacturing cell. In: Badiru, A.B. (Ed.) Handbook of Industrial and Systems Engineering, 2nd edn., pp. 291–297. CRC Press, Boca Raton, FL, USA (2014)

Bader, B.H.; Badar, M.A.; Rodchua, S.; McLeod, A.: A study of the balancing of lean thinking and stakeholder salience in decision-making. The TQM Journal 32(3), 441–460 (2020)

Belcher, J.; Kaldas, E.; Ellington, V.B.; Dave, D.S.: Developing a quality improvement plan for a small engineering firm in the USA with Six Sigma methodologies. Int. J. Prod. Qual. Manag. 24(1), 1–11 (2018)

Bettoni, L.; Mazzoldi, L.; Ferretti, I.; Zavanella L.; Zanoni S.: Integrated energy value analysis a new approach. In: Advances in Production Management Systems: Innovative Production Management towards Sustainable Growth. Springer, Cham, pp. 670–679 (2015)

Bhandari, P.; Badar, M.A.; Childress, V.: COVID-19 Surge planning in response to global pandemic in a healthcare setting: a lean six sigma approach. In: Proceedings of the 11th Int. Conf. on Industrial Engineering and Operations Mgmt, Singapore—Virtual, Mar 7–11 (2021). Accepted

Bogdanski, G.; Schonemann, M.; Thiede, S.; Andrew, S.; Herrmann, C.: An extended energy value stream approach applied on the electronics industry. In: 2012 Advances in Production Management Systems (APMS). Competitive Manufacturing for Innovative Products and Services, pp. 65–72 (2013)

Bunse, K.; Vodicka, M.; Schonsleben, P.; Brulhart, M.; Ernst, F.O.: Integrating energy efficiency performance in production management—gap analysis between industrial needs and scientific literature. J. Clean. Prod. 19(6–7), 667–679 (2011)

Chatterjee, R.; Sharma, V.; Mukherjee, S.; Kumar, S.: Value stream mapping based on energy and cost system for biodiesel production. Int. J. Sustain. Manuf. 3(2), 95–115 (2014)

Chong, M.Y.; Chin, J.F.; Loh, W.P.: Lean incipience spiral model for small and medium enterprises. Int. J. Ind. Eng.: Theory, Appl. Pract. 20(7–8), 487–501 (2013)

Costa, L.B.M.; Filho, M.G.; Fredendall, L.D.; Paredes, F.J.G.: Lean, six sigma and lean six sigma in the food industry: a systematic literature review. Trends Food Sci. Technol. 82, 122–133 (2018)

Dahlgaard, J.J.; Dahlgaard-Park, S.M.: Lean production, six sigma quality, TQM and company culture. TQM Magaz. 18(3), 263–281 (2006)

Dahlgaard, J.J.; Pettersen, J.; Dahlgaard-Park, S.M.: Quality and lean health care: a system for assessing and improving the health of healthcare organizations. Total Qual. Manag. Bus. Excell. 22(6), 673–689 (2011)

Drechsel, M.; Bornschlegl, M.; Spreng, S.; Bregulla, M.; Franke, J.: A new approach to integrate value stream analysis into a continuous energy efficiency improvement process. In: 2013 39th Annual Conference of the IEEE Industrial Electronics Society (IECON), Vienna, Austria, pp. 7502–7507 (2013)

Edgeman, R.L.; Dugan, J.P.: Six Sigma from products to pollution to people. Total Qual. Manag. Bus. Excell. 19(1–2), 1–9 (2008)

Erlach, K.; Westkamper, E.: Energiewertstrom—Der Weg zur energie-effizienten Fabrik [Energy value stream—The Path to an Energy Efficient Factory]. Fraunhofer Verlag, Stuttgart (2009)

Faulkner, W.; Badurdeen, F.: Sustainable value stream mapping (Sus-VSM): methodology to visualize and assess manufacturing sustainability performance. J. Clean. Prod. 85, 8–18 (2014)

Gholami, H.; Jamil, N.; Mat Saman, M.Z.; Streimikiene, D.; Sharif, S.; Zakuan, N.: The application of Green Lean Six Sigma. Bus. Strategy Environ. 30, 1913–1931 (2021)

Gonzalez-Aleu, F.; Van Aken, E.M.; Cross, J.; Glover, W.J.: Continuous improvement project within Kaizen: critical success factors in hospitals. The TQM Journal 30(4), 335–355 (2018)

Gutowski, T.G.; Branham, M.S.; Dahmus, J.; Jones, A.; Thiriez, A.: Thermodynamic analysis of resources used in manufacturing processes. Environ. Sci. Technol. 43(5), 1584–1590 (2009)

Hartini, S.; Ciptomulyono, U.; Sriyanto, M.A.: Manufacturing sustainability assessment using a lean manufacturing tool. Int. J. Lean Six Sigma 11(5), 957–985 (2020)

Jamil, N.; Gholami, H.; Mat Saman, M.Z.; Streimikiene, D.; Sharif, S.; Zakuan, N.: DMAIC-based approach to sustainable value stream mapping: towards a sustainable manufacturing system. Econ. Res.—Ekonomska Istraživanja 33(1), 331–360 (2020). https://doi.org/10.1080/1331677X.2020.1715236

Keskin, C.; Asan, U.; Kayakutlu, G.: Value stream maps for industrial energy efficiency. In: Cavallaro, F. (Ed.) Assessment and Simulation Tools for Sustainable Energy Systems: Theory and Applications, pp. 357–379. Springer, London, UK (2013)

Khan, S.A; Badar, M.A.; Alzaabi, M.: Productivity Improvement Using DMAIC in a Caravan Manufacturing Company. Int. J. of Productivity and Quality Management, 30, 2, 234–251 (2020)

Khan, S.A.; Kaviani, M.A.; Galli, B.J.; Ishtiaq, P.: Application of continuous improvement techniques to improve organization performance: a case study. Int. J. Lean Six Sigma 10(2), 542–565 (2019)

Kumar, M.; Antony, J.: Comparing the quality management practices in UK SMEs. Ind. Manag. Data Syst. 108(9), 1153–1166 (2008)

Kumar, S.; Bauer, K.F.: Exploring the use of lean thinking and six sigma in public housing authorities. Qual. Manag. J. 17(1), 29–46 (2010)

Kurdve, M.; Hanarp, P.; Chen, X.; Qiu, X; Zhang, Y.; Stahre, J.; Laring, J.: Use of environmental value stream mapping and environmental loss analysis in lean manufacturing work at Volvo. In: Swedish Production Symposium 2011, May 3–5, Lund, Sweden (2011)

Li, N.; Laux, C.; Antony, J.: How to use lean Six Sigma methodology to improve service process in higher education: a case study. Int. J. Lean Six Sigma 10(4), 883–908 (2019)

Meena, M.L.; Jain, R.; Kumar, P.; Gupta, S.; Dangayach, G.S.: Process improvement in an Indian automotive part manufacturing company: a case study. Int. J. Prod. Qual. Manag. 23(4), 524–551 (2018)

Muller, E.; Stock, T.; Schillig, R.: A method to generate energy value-streams in production and logistics in respect of time-and energy-consumption. Prod. Eng. Res. Develop. 8, 243–251 (2014)

Murugananthan, V.; Govindaraj, K.; Sakthimurugan, D.: Process planning through value stream mapping foundry. Int. J. Innov. Res. Sci., Eng. Technol. 3(3), 1140–1143 (2014)

Obraz, R.; Resetar, Z.; Pavicic, N.: Reducing delivery times of products using DMAIC methodology. Interdiscipl. Manag. Res. 10, 285–295 (2017)

Pondhe, R.; Asare, S.A.; Badar, M.A.; Zhou, M.; Leach, R.: Applying lean techniques to improve an emergency department. In: Proceedings of the IIE Annual Conference, May 20–24, Orlando, FL, USA (2006)

Rehman, T.; Khan, S.A.; Kusi-Sarpong, S.; Hassan, S.M.: Supply chain performance measurement and improvement system: a MCDA-DMAIC methodology. J. Model. Manag. 13(3), 522–549 (2018)

Rezaeian, J.; Parviziomran, I.; Iraj Mahdavi, I.: Increasing energy productivity in lean production system with energy oriented value-stream mapping. Int. J. Prod. Qual. Manag. 24(4), 495–506 (2018). https://doi.org/10.1504/IJPQM.2018.093449

Shamsuzzaman, M.; Alzeraif, M.; Alsyouf, I.; Khoo, M.B.C.: Using Lean Six Sigma to improve mobile order fulfilment process in a telecom service sector. Prod. Plann. Control 29(4), 301–314 (2018)

Sheikh, H.; Khalil, I.; Hossain, S.; Morshed, S.M.R.: Reducing defects in denim weaving by applying six sigma methodology: a case study. Global J. Human-Soc. Sci. (H) 19(3), 8–16 (2019)

Solding, P.; Gullander, P.: Concepts for simulation based value stream mapping. In: Proceedings of the 2009 Winter Simulation Conference (WSC), Austin, TX, USA, pp. 2231–2237 (2009)

Souza, T.A.; Roehe Vaccaro, G.L.; Lima, R.M.: Operating room effectiveness: a lean health-care performance indicator. Int. J. Lean Six Sigma 11(5), 987–1002 (2020)

Taylor, J.; Sinn, J.W.; Ulmer, J.M.; Badar, M.A.: Proposed progression of lean six sigma. J. Technol. Studies 41(1), 2–8 (2015)

Valles, A.; Sanchez, J.; Noriega, S.; Nunez, B.G.: Implementation of six sigma in a manufacturing process: a case study. Int. J. Ind. Eng.: Theory, Appl. Pract. 16(3), 171–181 (2009)

Verma, N.; Sharma, V.: Lean modelling—a case study for Indian SME. Int. J. Technol. Res. Eng. 2(7), 991–998 (2015)

Verma, N.; Sharma, V.: Energy value stream mapping a tool to develop green manufacturing. Procedia Eng. 149, 526–534 (2016)

Verma, N.; Sharma, V.: sustainable competitive advantage by implementing lean manufacturing: a case study for Indian SME. Mater. Today: Proc. 4(8), 9210–9217 (2017)

Verma, N.; Sharma, V.: A literature review on energy value stream mapping (EVSM). International Journal of Advanced Science and Technology, 27, Special Issue, 01–08 (2019)

Womack, J.P.; Jones, D.T.: Lean Thinking: Banish Waste and Create Wealth in Your Corporation, 2nd edn. Simon & Schuster, New York, NY, USA (2003)

Zhang, Z.; David, J.: An entropy-based approach for assessing the operation of production logistics. Expert Syst. Appl. 119, 118–127 (2019). https://doi.org/10.1016/j.eswa.2018.10.044

Zhenyuan, J.; Xiaohong, L.; Wei, W.; Defeng, J.; Lijun, W.: Design and implementation of lean facility layout system of a production line. Int. J. Ind. Eng.: Theory, Appl. Pract. 18(5), 260–269 (2011)

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Verma, N., Sharma, V. & Badar, M.A. Entropy-Based Lean, Energy and Six Sigma Approach to Achieve Sustainability in Manufacturing System. Arab J Sci Eng 46, 8105–8117 (2021). https://doi.org/10.1007/s13369-021-05826-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13369-021-05826-x