Abstract

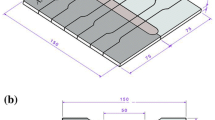

This study investigates the successful joining methods of dissimilar metals of AZ31B Mg and AA7075-T6 Al alloys. The specimens were joined by using open-flame heating system and investigated the effect of the friction stir welding (FSW) process parameters on the welding quality, transverse rupture strength (TRS), tensile strength, microhardness, and microstructure of the resulting specimens. The welding experiments were conducted based on the Taguchi mixed-orthogonal-array for tests, L16 (42 × 22), at a constant spindle speed of 500 rpm using a K10 grade carbide mixing tool with two different tilt angles (0° and 3°), and two tool tip geometries (square and triangle). The specimens were successfully welded, and the test results revealed that the welding temperatures and forces had the strongest effect on the welding quality. The achieved maximum tensile strength and TRS were approximately 122.1 MPa and 712.1 MPa, respectively, at a tool travel speed of 20 mm/min, tool offset value of 0.75 mm, tool tilt angle of 3°, and using a triangle tool tip. The microstructural analysis indicated that a dynamically recrystallized and grain refinement structure formed in the welded zone depending on the temperature and on the excessive deformation. The increase in the microhardness values depends on the intermetallic compounds ratio and fine-grained structure in the welded zone.

Similar content being viewed by others

References

Baghdadi, A.H.; Rajabi, A.; Mohamad Selamat, N.F.; Sajuri, Z.; Omar, M.Z.: Effect of post-weld heat treatment on mechanical behaviour and dislocation density of FSWed Al 6061. Mater. Sci. Eng. A 754, 728–734 (2019). https://doi.org/10.1016/j.msea.2019.03.017

Dorbane, A.; Mansoor, B.; Ayoub, G.; Shunmugasamy, V.C.; Imad, A.: Mechanical, microstructural and fracture properties of dissimilar welds produced by friction stir welding of AZ31B and Al6061. Mater. Sci. Eng. A 651, 720–733 (2016). https://doi.org/10.1016/j.msea.2015.11.019

Liu, L.; Ren, D.; Liu, F.: A review of dissimilar welding techniques for magnesium alloys to aluminum alloys. Materials (Basel) 7, 3735–3757 (2014). https://doi.org/10.3390/ma7053735

Karam, A.; Mahmoud, T.S.; Zakaria, H.M.; Khalifa, T.A.: Friction stir welding of dissimilar A319 and A413 cast aluminum alloys. Arab. J. Sci. Eng. 39, 6363–6373 (2014). https://doi.org/10.1007/s13369-014-1220-6

Liu, P.; Li, Y.; Geng, H.; Wang, J.: Microstructure characteristics in TIG welded joint of Mg/Al dissimilar materials. Mater. Lett. 61, 1288–1291 (2007). https://doi.org/10.1016/j.matlet.2006.07.010

Ben-Artzy, A.; Munitz, A.; Kohn, G.; Bronfin, B.; Shtechman, A.: Joining of light hybrid constructions made of magnesium and aluminum alloys. In: TMS Annual Meeting, pp. 295–302 (2002)

Chi, C.T.; Chao, C.G.; Liu, T.F.; Lee, C.H.: Aluminum element effect for electron beam welding of similar and dissimilar magnesium-aluminum-zinc alloys. Scr. Mater. 56, 733–736 (2007). https://doi.org/10.1016/j.scriptamat.2007.01.028

Bannour, S.; Abderrazak, K.; Mattei, S.; Masse, J.E.; Autric, M.; Mhiri, H.: The influence of position in overlap joints of Mg and Al alloys on microstructure and hardness of laser welds. J. Laser Appl. 10, 10 (2013). https://doi.org/10.2351/1.4792615

Gao, M.; Mei, S.; Li, X.; Zeng, X.: Characterization and formation mechanism of laser-welded Mg and Al alloys using Ti interlayer. Scr. Mater. 67, 193–196 (2012). https://doi.org/10.1016/j.scriptamat.2012.04.015

Gao, Y.; Morisada, Y.; Fujii, H.; Liao, J.: Dissimilar friction stir lap welding of magnesium to aluminum using plasma electrolytic oxidation interlayer. Mater. Sci. Eng. A 711, 109–118 (2018). https://doi.org/10.1016/j.msea.2017.11.034

Asl, N.S.; Mirsalehi, S.E.; Dehghani, K.: Effect of TiO2 nanoparticles addition on microstructure and mechanical properties of dissimilar friction stir welded AA6063-T4 aluminum alloy and AZ31B-O magnesium alloy. J. Manuf. Process. 38, 338–354 (2019). https://doi.org/10.1016/j.jmapro.2019.01.023

Niu, P.L.; Li, W.Y.; Vairis, A.; Chen, D.L.: Cyclic deformation behavior of friction-stir-welded dissimilar AA5083-to-AA2024 joints: effect of microstructure and loading history. Mater. Sci. Eng. A 744, 145–153 (2019). https://doi.org/10.1016/j.msea.2018.12.014

Li, W.; Niu, P.L.; Yan, S.R.; Patel, V.; Wen, Q.: Improving microstructural and tensile properties of AZ31B magnesium alloy joints by stationary shoulder friction stir welding. J. Manuf. Process. 37, 159–167 (2019). https://doi.org/10.1016/j.jmapro.2018.11.014

Li, P.; You, G.; Wen, H.; Guo, W.; Tong, X.; Li, S.: Friction stir welding between the high-pressure die casting of AZ91 magnesium alloy and A383 aluminum alloy. J. Mater. Process. Technol. 264, 55–63 (2019). https://doi.org/10.1016/j.jmatprotec.2018.08.044

Zhao, Y.; Lu, Z.; Yan, K.; Huang, L.: Microstructural characterizations and mechanical properties in underwater friction stir welding of aluminum and magnesium dissimilar alloys. Mater. Des. 65, 675–681 (2015). https://doi.org/10.1016/j.matdes.2014.09.046

Ji, S.; Meng, X.; Liu, Z.; Huang, R.; Li, Z.: Dissimilar friction stir welding of 6061 aluminum alloy and AZ31 magnesium alloy assisted with ultrasonic. Mater. Lett. 201, 173–176 (2017). https://doi.org/10.1016/j.matlet.2017.05.011

Hernández-García, D.; Saldaña-Garcés, R.; García-Vázquez, F.; Gutiérrez-Castañeda, E.J.; Deaquino-Lara, R.; Verdera, D.: Friction stir welding of dissimilar AA7075-T6 to AZ31B-H24 alloys. MRS Adv. 2(64), 4055–4063 (2017). https://doi.org/10.1557/adv.2017

Tabasi, M.; Farahani, M.; Givi, M.K.B.; Farzami, M.; Moharami, A.: Dissimilar friction stir welding of 7075 aluminum alloy to AZ31 magnesium alloy using SiC nanoparticles. Int. J. Adv. Manuf. Technol. 86, 705–715 (2016). https://doi.org/10.1007/s00170-015-8211-y

Lambiase, F.; Paoletti, A.; Di Ilio, A.: Forces and temperature variation during friction stir welding of aluminum alloy AA6082-T6. Int. J. Adv. Manuf. Technol. 99, 337–346 (2018). https://doi.org/10.1007/s00170-018-2524-6

Yan, Y.B.; Zhang, Z.W.; Shen, W.; Wang, J.H.; Zhang, L.K.; Chin, B.A.: Microstructure and properties of magnesium AZ31B-aluminum 7075 explosively welded composite plate. Mater. Sci. Eng. A 527, 2241–2245 (2010). https://doi.org/10.1016/j.msea.2009.12.007

McLean, A.A.; Powell, G.L.F.; Brown, I.H.; Linton, V.M.: Friction stir welding of magnesium alloy AZ31B to aluminium alloy 5083. Sci. Technol. Weld. Join. 8, 462–464 (2003). https://doi.org/10.1179/136217103225009134

Somasekharan, A.C.; Murr, L.E.: Microstructures in friction-stir welded dissimilar magnesium alloys and magnesium alloys to 6061-T6 aluminum alloy. Mater. Charact. 52, 49–64 (2004). https://doi.org/10.1016/j.matchar.2004.03.005

Verma, J.; Taiwade, R.V.; Reddy, C.; Khatirkar, R.K.: Effect of friction stir welding process parameters on Mg-AZ31B/Al-AA6061 joints. Mater. Manuf. Process. 33, 308–314 (2018). https://doi.org/10.1080/10426914.2017.1291957

Yan, J.; Xu, Z.; Li, Z.; Li, L.; Yang, S.: Microstructure characteristics and performance of dissimilar welds between magnesium alloy and aluminum formed by friction stirring. Scr. Mater. 53, 585–589 (2005). https://doi.org/10.1016/j.scriptamat.2005.04.022

Lee, K.J.; Kwon, E.P.: Microstructure of stir zone in dissimilar friction stir welds of AA6061-T6 and AZ31 alloy sheets. Trans. Nonferrous Metals Soc. China (Engl. Ed.) 24, 2374–2379 (2014). https://doi.org/10.1016/s1003-6326(14)63359-8

Fu, B.; Qin, G.; Li, F.; Meng, X.; Zhang, J.; Wu, C.: Friction stir welding process of dissimilar metals of 6061-T6 aluminum alloy to AZ31B magnesium alloy. J. Mater. Process. Technol. 218, 38–47 (2015). https://doi.org/10.1016/j.jmatprotec.2014.11.039

Malarvizhi, S.; Balasubramanian, V.: Influences of tool shoulder diameter to plate thickness ratio (D/T) on stir zone formation and tensile properties of friction stir welded dissimilar joints of AA6061 aluminum-AZ31B magnesium alloys. Mater. Des. 40, 453–460 (2012). https://doi.org/10.1016/j.matdes.2012.04.008

Kwon, Y.J.; Shigematsu, I.; Saito, N.: Dissimilar friction stir welding between magnesium and aluminum alloys. Mater. Lett. 62, 3827–3829 (2008). https://doi.org/10.1016/j.matlet.2008.04.080

Bilgin, M.; Karabulut, Ş.; Özdemir, A.: Study on the mechanical properties of dissimilar friction stir welding of AA 7075 T6 and AZ31B Alloys. In: Proceedings of the 2018 9th International Conference on Mechanical and Aerospacce Engineering ICMAE 2018, pp. 467–471 (2018). https://doi.org/10.1109/icmae.2018.8467679

Firouzdor, V.; Kou, S.: Formation of liquid and intermetallics in Al-to-Mg friction stir welding. Metall. Mater. Trans. A Phys. Metall. Mater. Sci. 41, 3238–3251 (2010). https://doi.org/10.1007/s11661-010-0366-4

Mohammadi, J.; Behnamian, Y.; Mostafaei, A.; Gerlich, A.P.: Tool geometry, rotation and travel speeds effects on the properties of dissimilar magnesium/aluminum friction stir welded lap joints. Mater. Des. 75, 95–112 (2015). https://doi.org/10.1016/j.matdes.2015.03.017

Elangovan, K.; Balasubramanian, V.; Valliappan, M.: Influences of tool pin profile and axial force on the formation of friction stir processing zone in AA6061 aluminium alloy. Int. J. Adv. Manuf. Technol. 38, 285–295 (2008). https://doi.org/10.1007/s00170-007-1100-2

Venkateswaran, P.; Reynolds, A.P.: Factors affecting the properties of Friction Stir Welds between aluminum and magnesium alloys. Mater. Sci. Eng. A 545, 26–37 (2012). https://doi.org/10.1016/j.msea.2012.02.069

Mofid, M.A.; Abdollah-Zadeh, A.; Gür, C.H.: Investigating the formation of intermetallic compounds during friction stir welding of magnesium alloy to aluminum alloy in air and under liquid nitrogen. Int. J. Adv. Manuf. Technol. 71, 1493–1499 (2014). https://doi.org/10.1007/s00170-013-5565-x

Sato, Y.S.; Park, S.H.C.; Michiuchi, M.; Kokawa, H.: Constitutional liquation during dissimilar friction stir welding of Al and Mg alloys. Scr. Mater. 50, 1233–1236 (2004). https://doi.org/10.1016/j.scriptamat.2004.02.002

Hou, Z.; Sheikh-Ahmad, J.; Jarrar, F.; Ozturk, F.: Residual stresses in dissimilar friction stir welding of AA2024 and AZ31: experimental and numerical study. J. Manuf. Sci. Eng. 140, 051015 (2018). https://doi.org/10.1115/1.4039074

Shah, L.H.; Othman, N.H.; Gerlich, A.: Review of research progress on aluminium–magnesium dissimilar friction stir welding. Sci. Technol. Weld. Join. 23, 256–270 (2018). https://doi.org/10.1080/13621718.2017.1370193

Kou, S.; Firouzdor, V.: Al-to-Mg friction stir welding: effect of positions of Al and Mg with respect to the welding tool. Weld. J. 88, 213–224 (2009)

Ramkumar, T.; Selvakumar, M.; Narayanasamy, P.; Ayisha Begam, A.; Mathavan, P.; Arunraj, A.: Studies on the structural property, mechanical relationships and corrosion behaviour of Inconel 718 and SS 316L dissimilar joints by TIG welding without using activated flux. J. Mater. Process. Technol. 30, 290–298 (2017). https://doi.org/10.1016/j.jmapro.2017.09.028

Acknowledgements

The author wishes to thank Gazi University Scientific Research Projects Coordination Unit for the financial support of this study [Grant Number 59/2016-01].

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Bilgin, M., Karabulut, Ş. & Özdemir, A. Investigation of Heat-Assisted Dissimilar Friction Stir Welding of AA7075-T6 Aluminum and AZ31B Magnesium Alloys. Arab J Sci Eng 45, 1081–1095 (2020). https://doi.org/10.1007/s13369-019-04244-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13369-019-04244-4