Abstract

The polymer inclusion membranes (PIMs) containing Cellulose triacetate as polymer base, 2-NPOE as a plasticizer, and Calix[4]resorcinarene (RC8) as a carrier were prepared and characterized. Microstructure and surface of PIMs were characterized by scanning electron microscope, FTIR, UV/vis spectroscopy, and Thermogravimetric Analysis, respectively. In order to obtain information on the composition and interactions that may manifest between the constituents of the membrane. The PIMs were applied in the elimination of Methylene Blue (MB) dye from model solution as synthetic aqueous wastewater. Furthermore, the effects of different parameters such as internal and external PIMs environment on the transport performance of MB were also investigated. The results confirming that the content of the carrier and plasticizer in the membrane had a significant impact on the property of PIMs. The transport of dye was in line with the first-order kinetics equation. The highest flux value "8.88 × 10–7 mol.m−2 s−1" was obtained with a calix [4] resorcinarene as a transporter in polymer inclusion membrane at pH 11 in the feed and 0.3 M HCl in the stripping phase when MB initial concentration was 100 mg/L. The membrane has better stability under optimum conditions and maximum transport was observed after 30 h of permeation time.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Wastewater discharges are a primary source of releases of persistent organic pollutants to the environment, as well as textile industrial discharges of dyes, which constitute a serious environmental problem particularly linked to the toxicity of some of them. Therefore, their elimination represents an important issue for environmental chemistry (Ghoreyshi et al. 2003). The textile industry is one of the largest and most ancient in the world, it consumes substantial volumes of water and chemicals for wet processing of textiles. These chemicals are used for scouring, bleaching, dyeing, printing, and finishing. Discharge of untreated textile effluents in the environment is a widespread problem; dyes can be harmful to humans, acting as irritants for eyes and skin. There are more than 8000 chemical products associated with the dyeing process listed in the Color Index (Meyer 1981; Zoollinger 1987). These dyes include several structural varieties of dyes, such as acidic, reactive, basic, disperse, azo, diazo, anthraquinone-based and metal-complex dyes. Basic dyes are water-soluble; it charged positively in solution and is attracted electrostatically to substrates with a negative charge. Cationic dyes can have either the positive charge localized on an ammonium group, or it can be delocalized charge over the skeleton of the dye cation. Methylene blue is a cationic dyestuff, the chemical formula is C16H18N3SCl, and the molecular weight is 319.85 g mol-1. It is used for coloring in the textile industry and also for preventing fungus reproduction in fish breeding farms. Several techniques have been applied to treat the textile dyeing wastewater, including adsorption, precipitation, membrane filtration, photochemical degradation and electrolytic treatments (Ashraf et al. 2016; Muthuraman et al. 2006; Venkatestwaran et al. 2006; Forgacs et al. 2004). In contrast, adsorption and coagulation can generate a huge amount of sludge. Indeed the oxidation and biodegradation are invalid to the heavy metal ion and inorganic salt removals. Thus, effective technology for textile wastewater treatment can be preferred over conventional treatment methods. Such as extraction, adsorption, absorption, and distillation. The removal of organic pollutants by the separation method based on extraction consumes large quantity of solvents. To overcome this drawback, membrane processes are alternative separation technologies to conventional separation techniques. However, these liquid membranes also have certain drawbacks such as the release of the solvent and that of the transporter to the external medium which lead to a reduction in their stability and a limit to their application in the industrial field. In addition, the introduction of artificial or biological membranes can present a good alternative to liquid membranes. These membranes include bulk liquid membranes (BLM) (Bizek et al. 1992), liquid emulsion membranes (ELM) (Manzak et al. 2004), liquid surface active membranes (LSM) and supported liquid membranes (SLM) (Ashraf et al. 2016). A new type of liquid membrane called polymeric inclusion membranes (PIM) is being developed and applied successfully for the removal of organic molecules from aqueous solutions (Benosmane et al. 2018a, b). The inclusion polymer membrane (PIMs) proposed by Sugiura (1987), obtained by the incorporation of transporters within the plasticized polymer caught our attention for its selectivity and good stability. These two points are important from the perspective of a membrane application. The purpose of this research work is to develop and characterize inclusion polymer membranes based on a mixture of two polymers cellulose acetate and cellulose triacetate with calix [4] resorcinarene as transporter and NPOE as a plasticizer. This membrane was applied in the elimination of methylene blue from aqueous synthetic wastewater. A variety of parameters controlling the transport of methylene blue dye have been explored. These factors include effective pH range in the feed solution, acid concentration in the strip solution, initial dye concentration, carrier nature and membrane stability.

Materials and methods

Reagents

The structure and abbreviation of transporter and plasticizer used in this study are given in Fig. 1 The transporter (C-Octyle) calix [4] resorcinarene, abbreviated RC8 has been synthesized (Hadidi et al. 2006).

Methylene blue, Resorcinol, aldehyde, ethanol, hydrochloric acid, dichloromethane, Cellulose triacetate (CTA, molecular weight Mw = 72,000 – 74,000, with an acetyl content of about 43.6%), acetate of cellulose (CA, molecular weight Mw = 50,000, with an acetyl content of about 39.7%) and 2-nitrophenyl octylether (2-NPOE) are reagents of analytical grade supplied by Sigma-Aldrich.

Preparation of polymeric inclusion membranes

The PIMs were prepared according to the procedure reported by Sugiura (1987), the quantity of each constituent depends on the series of experiments to be carried out. Thus, for the mixture of CTA and CA, 10 ml of a solution of polymers in the appropriate solvent, calix [4] resorcinarene (0–0.06 g/g of polymer mixture) and the plasticizer NPOE is poured into a box. The mixture is left at room temperature. The film formed is then carefully peeled from the bottom of the Petri dish and immersed in deionized water for 24 h. The average thickness of the PIMs produced was determined by measuring four corners of the membrane using a digital micrometer of the type: Mitutoyo Corporation, Japan.

Analysis of methylene blue (MB)

The effect of the studied parameters on the transport of MB was analyzed during the 30 h transport experiment on a two-compartment cell (Fig.2). Samples of 2 mL were manually extracted with a pipette from both half-cells each six-hour (five samples in total), and the methylene blue quantification in the transport experiments was carried out using a UV/vis spectrophotometer Junway 6800. Based on the previous work on methylene blue (Benosmane et al. 2015a), it is found that there is no influence of pH in aqueous solution on the characteristic band's absorption of methylene blue in UV/vis spectroscopy. The MB was determined spectroscopically by UV–Vis at λ = 665 nm. The Synthetic textile wastewater was prepared using methylene blue (100 mg/L) dye with addition of chemicals (Table 1).

Transport experiments

A typical laboratory-scale device was used for methylene blue transport experiments through the PIM. The PIM cell consists of two compartments made of Teflon with a maximum capacity of 230 ml separated by the PIM (Fig. 2) (Benosmane et al. 2015b). The PIM area exposed to the aqueous phase was 07.08 cm2. In order to minimize the boundary layer thickness, both the source and stripping compartments were provided with a mechanical stirrer adjusted to 600 rpm (Based on previous research work on the removal of organic contaminants such as citric acid (Benosmane et al. 2018a) and phenol (Benosmane et al. 2018b) using the same membranes composition and cell for transport, we observed that the optimal stirring rate was 600 rpm. thus we have chosen 600 rpm). One of them contained 100 mg/L of MB as the feed phase, and the other, the stripping phase, contained deionized water. Transport can take place by diffusion. All transport experiments were carried out in duplicate at 25 ± 1 °C. The reported error bars in all figures represent the standard deviation of the data (%RSD). The start of the process was marked by simultaneously switching on both stirrers.

The performance of the system was studied in terms of its MB removal (%), defined by Eq. (1) and its initial flux (J0), calculated by Eq. (2)

where \(\left[ {{\mathbf{Methylene}} {\mathbf{Blue}}} \right]_{{{\varvec{s}},{\varvec{t}}}} \user2{ }\) refers to the MB concentration in the stripping phase at time t and \(\left[ {{\mathbf{Methylene}} {\mathbf{blue}} } \right]_{{{\varvec{f}},0}}\) refers to the initial concentration of MB in the feed phase

where V is the volume of feed phase, S the exposed surface area of the PIM.

The kinetics of the transport process through PIMs is described by the first-order reaction (Nghiem et al. 2006)

where Ct (mg/L) is the MB concentration in the feed solution at time t, C0 is the initial MB concentration in the feed solution (mg/L), k is rate constant(s−1) and t is the transport time(s).

Analysis of PIMs

-

The observation of the different membranes by scanning electron microscopy was carried out using a microscope of the ESEM XL30 PHILIPS type, operating at 10 kV.

-

The Infrared analysis was carried out on a Perkin Elmer (Spectrume one) type spectrometer with Fourier transform whose resolution is fixed at 2 cm−1. The frequency range scanned covers the mid-infrared range 400–4000 cm−1. The spectra are acquired in transmittance mode (32 scans).

-

The Ultraviolet (UV) analysis was carried out on a Junway 6800 UV–Vis spectrophotometer with an optical path of 1 cm.

-

The TGA thermogravimetric analysis was carried out using a device of the SETARAM TG 96 type with a heating rate of 10 °C min−1 under an atmosphere of nitrogen N2.

Water absorption capacity (%)

The percentage of the presence of water inside the membrane can be evaluated by immersing the membrane in a distilled water bath for 24 h; the excess water is then removed using a filter paper. Then weighed in an Ohaus type balance with an accuracy of ± 0.1 mg, this wet membrane is placed in an oven at 105 (°C) for 24 h and the percentage of water present is determined using the following equation (Benosmane et al. 2010):

mh: mass of the wet membrane.

ms: mass of the dry membrane.

Porosity of PIMs

The porosity of the developed PIMs was determined using the following equation (Benosmane et al.2010):

when:

mh: mass of the wet membrane (g).

ms: mass of the dry membrane (g).

A: membrane surface in cm2.

L: thickness of the membrane.

ρe: density of distilled water (g/cm3).

Results and discussion

Physical–chemical characterization of the developed PIMs

The membranes made from CTA alone and a mixture of cellulose triacetate (CTA) and cellulose acetate (CA) are characterized by different physicochemical techniques, in order to study their morphology, determine the nature of the interactions that can manifest between the constituents, define the state of the membrane inside the matrix.

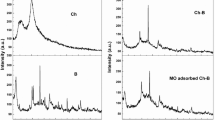

Morphology of the developed MPIs

The SEM images of the membrane based on the CTA, the CA alone and of the mixture of the two polymers containing 0.05 g calix [4] resorcinarene (RC8) /g polymers and 0.4 mL of 2-NPOE/g polymers are presented in Fig. 3. The membrane of the AC has a homogeneous dense surface with a uniform structure, the same nature of the surface is observed in the case of CTA-based PIM. In addition, the PIM based on a mixture of the two polymers shows a dense smooth surface. On the other hand, the membranes containing the calix [4] resorcinarene (RC8) are a smoother and firmer surface with dense structures suggesting pores filled by transporters because of the plasticization of PIM (Cho et al. 2011).

: SEM Micrographs of developed PIMs; a CTA 100% + RC8(0.0( g/g polymers) + 2-NPOE (0.4 mL)/g polymers, b (CTA 75% + CA 25%)% + RC8(0.0( g/g polymers) + 2-NPOE (0.4 mL)/g polymers, c (CTA 50% + CA 50%)% + RC8(0.0(g/g polymers) + 2-NPOE (0.4 mL)/g polymers, d (25%CTA + 75%CA) % + RC8(0.0(g/g polymers) + 2-NPOE (0.4 mL)/g polymers

Spectroscopic study by FTIR

Infrared spectroscopy is a very useful technique for analyzing the chemical structure of a polymer. This technique is often used to characterize the surface of the membranes, in fact, this technique provides information on the interactions likely to appear within the system: support-plasticizer-transporter by the appearance or disappearance of the bands (formation of the bonds by a link covalent), their displacements. This technique can also be used to verify the absence of the solvent after evaporation in the preparation of the membranes. The vibration energies of the measured chemical bonds make it possible to identify the nature of the functional groups present in the sample.

The FTIR spectra of the PIMs produced are reported in Fig. 4. We have noticed that all the peaks obtained with the reference membrane (based on CA or CTA alone) are found on the FTIR spectra of the other membranes containing the calix [4] resorcinarene (RC8) and the 2-NPOE. The presence of RC8 in the PIM matrix reveals new absorption bands at 1497, 1502 and 1510 cm−1. These new bands are attributed to the bonds (C=C) Ar in the benzene rings of calix [4] resorcinarenes. The absorption band of the carbonyl group of cellulose acetate (C=O) which is at 1639 cm−1 is moved after inclusion of calix [4] resorcinarene around (1746 cm−1). This may be justified by the compromise of several factors such as the hydrogen bond and the hydrophobic and steric interactions existing between Carrier and support. It should be noted that the same findings were observed for CTA-based PIM. Indeed, the evaporation process causes changes in intermolecular interactions of the polymer chains. On the other hand, the characteristic band of the hydroxyl groups of calix [4] resorcinarene is found to be confused with that of the hydroxyl group of the polymer CTA and CA. Furthermore, we did not observe any bands other than those already reported, which excludes the hypothesis of the formation of chemical bonds (covalent bond) between the polymer and the transporter (Benosmane et al. 2010).

In fact, in Fig. 4, the FTIR spectra of the different PIMs show differences in the shape of the absorption band characteristic of the alcohol function in the range from 3250 to 3600 cm−1. This is explained by the modification of the surface of the membrane based on the 50% mixture of the two polymers CTA and CA. Likewise, the ratio of the absorption intensities of the two bands characteristic of both the alcohol function and the CH2 group in PIM based on 100% CTA is modified after the addition of second polymer CA confirming thus that interaction between the two polymers exists, it is physical in nature of hydrogen bonding type.

Thermogravimetric analysis (TGA) of PIMs

Figure 5 shows the thermograms of the membranes developed in this study. The degradation of the CA-based membrane begins at 320 °C corresponding to the breaking of the polymer chains which is in agreement with the literature (Benosmane et al. 2010). The carrier (RC8) in its pure state begins to degrade from 380 °C (Benosmane et al. 2016). If there was no interaction between the CTA and the CA, two mass losses should be obtained, one for the CTA polymer and the other corresponding to the CA. But in our case we observe a single loss due to the mixture of the two polymers CA–CTA thus forming a block and they are perfectly miscible. Indeed the characteristic thermogram of PIM based on the mixture of CA-CTA polymers shows a single loss at around 341 °C characteristic of the degradation of polymer chains; the Membrane-based on 100% CTA shows the same loss temperature confirming thus the good miscibility of the two polymers within the membrane. In the case of PIM based on a mixture: support-plasticizer-transporter, two degradations are observed, the first starts from 146 up to 229 °C corresponding to the volatilization of the 2-NPOE plasticizer, and the second at around 348 °C corresponding to the degradation of the polymer chains of the two polymers. This result is probably due to the specific interactions between the transporter and the support which is in agreement with the results of the FTIR spectroscopic analysis. This technique allowed us to conclude that the PIMs developed are free of traces of solvent molecules.

UV–Vis Spectroscopic study

Ultra-Violet (UV) tells us about the nature of the groups existing in the membrane matrix, it proves the existence of interactions between different constituents of the membrane. Figure 6 shows the different UV spectra produced from the synthesize PIMs. The transporter RC8 absorbs in the vicinity of 291 nm, this wavelength corresponds to the electronic transition of type n-π * characteristic of the alcohol function in the calix [4] resorcinarene RC8. Similarly, the PIM based on 100% CTA shows an absorption band in the vicinity of 207 nm representing the electronic transition of type π–π * characteristic of the carbonyl groups (C=O) of the acetyl function in the polymer. The AC has two absorption bands, the first at 221 nm characteristic of the acetyl group (C=O) and the second at 279 nm characteristic of the alcohol (OH) function not acetylated. The addition of the RC8 transporter during the preparation of the PIM based on 100% CTA shows the appearance of a new band at 285 nm characteristic of the alcohol function in RC8, but we note that this band is displaced with 6 nm compared to the absorption wavelength of RC8 alone, this can be explained by the presence of specific interaction of the hydrogen bond type between RC8 and the carbonyl function in the CTA polymer constituting the support of PIM. The mixture of CTA and CA polymers shows two characteristic bands at 202 and 280 nm, one corresponding to the carbonyl function in the two polymers and the second corresponding to the alcohol function of the CA polymer.

Thickness, water absorption capacity and porosity of the PIMs

We have determined the thickness, porosity and water absorption capacity of the PIMs produced. As shown in Table 2, the inclusion of the transporter (RC8) and the plasticizer (2-NPOE) in the organic phase of the membrane based on the polymer blend induces a drastic increase in its thickness. Similarly, we note that the weight of the membrane increases after the introduction of the plasticizer and carrier. The addition of CA modifies the hydrophilicity of PIM, indeed PIM based on 100% CTA contains 2.54% water, the percentage increases from 7.69 to 17.99% due to the percentage increase of CA in the PIM. The membrane-based on cellulose acetate shows the highest percentage of presence of water equal to 37.81%. Similarly, the addition of the plasticizer to the PIM based on the mixture of 75% CTA and 25% CA, does not modify its hydrophilicity, this suggests that the plasticizer occupies the pores of the membrane as well as the polymer chains so that the addition of the transporter which has aliphatic chains (with eight carbons) oriented upward (in the air) decreases the percentage of water present in the PIM, indeed the molecules of the transporter was deposited on the surface of the membrane which is already observed by SEM, in fact, the aliphatic chains will prevent the membrane from absorbing more water. The membrane surface becomes hydrophobic after the addition of plasticizer (2-NPOE) and the transporter (RC8).

The synergistic effect of the carrier and the plasticizer reduces the percentage of water presence of the PIM to 5.05. The diagram proposed in Fig. 7 illustrates the interactions likely to exist between the different constituents of PIM. In addition, we have determined the porosity of the PIMs developed, we note that the PIM keeps the same porosity after the addition of the plasticizer, on the other hand after the addition of the carrier the porosity decreases by half, likewise, the membrane based on CA (0.4721) is porous compared to the CTA-based membrane (0.0184).

Application of PIMs for removal of methylene blue

Effect of base polymers for PIM preparation

CTA, CA and the mixture of CTA/CA with different proportion, In this study, the results (see Table 3) prove that membranes based on CA alone and the mixture of CTA with CA do not show the best performance in the Methylene Blue. But in the case of CTA, we have observed an important percent of elimination, due to the higher ionizable groups participating in dipole–dipole interactions allowing a better inclusion and immobilization of carrier RC8. The membrane matrix with CTA is a polar polymer with several acetyl groups that are capable of forming highly orientated hydrogen bonds with carrier RC8 that enhance complexation rate at the interface feed phase/membrane surface.

Transport kinetics

The kinetics of the transport of MB through the PIM is given in Fig. 8a, the concentration of MB decreases rapidly in the feeding phase as well as a significant increase in MB in the reception phase during the first step in the separation process. After 25 h of transport, note that the concentrations of methylene blue in the feeding phase and in the reception phase are respectively: 25.0 mg/L and 72 mg/L. these results confirm that the PIMs prepared for RC8 bases are effective for the transfer of methylene blue. The kinetics of the transport process through the IMPs is described by the first-order equation as Eq. (1). The k values are calculated from the graphs of Ln (C0/Ct) as a function of time. The relation of Ln (C0/Ct) as a function of time is linear as expected from Eq. (1), and Fig. 8b gives an acceptable value of the correlation coefficient R2 = 0.992 with a constant rate k = 1.75.10–5 s−1.

Effect of acid concentration in the stripping phase

Different concentrations of hydrochloric acid in the reception phase were tested on the flow of MB through the PIM, ranging from 0.1 M to 0.3 M. The results are given in Table 4. Indeed the increase in the acid concentration in the reception phase increases the MB transport linearly until a maximum quantity of MB is obtained, i.e., 88%, this result can be explained by the high acid concentration which reduces the dissociation of the support-dye complex formed inside the liquid membrane, thus reaching a maximum value.

Effect of the dye concentration

The variation in flux with a variable concentration of dye in the feeding phase is studied. Figure 9 demonstrates the selectivity of extraction of prepared PIMs as a function of the concentration of dye in the feed phase. The extraction efficiency increased with the MB dye content of the membrane till 100 ppm, Fig. 9. Further increase in the MB content did not result in any enhancement in the extraction efficiency. The higher concentration of MB causes membrane saturation which lowers the effective area available for transportation, and also impedes the mobility of MB cations within the feed phase (Forgács et al. 2004) studies have reported similar behavior of PIM in metal–organic systems (Benosmane et al. 2015b). Therefore, 100 ppm of MB solution is selected for optimization of other experimental parameters. It is important to note that the presence of 100 ppm dye in industrial waste is considered high and optimization at this concentration is relevant in the industrial context.

Effect of feed phase pH

The dependence of the MB extraction with pH solutions of feed phase in the range of 3 to 11 was studied. It was found that with the increase of pH (up to 11) the transport of MB was more effective, as shown in Table 5, an increase in pH of the aqueous feed phase solution correspondingly increased the flux of the methylene blue when the concentration of HCl in stripping phase was equal to 0.3 M. The increase in the extraction at higher pH is the result of the effect of hydroxy ions, which enhances the formation of extractable target complex species in the organic membrane phase (occurs as counter-ion). Indeed the amount of MB adsorbed from the bulk solution increases with pH at the basic region. Lower absorption capacity in the acidic region may be due to the repulsive effect between extracting site and MB, while the higher absorption capacity noted at basic pH may be due to conversion of hydrophobic methylene blue into hydroxyl-methylene blue which is hydrophilic. Thus, an interaction occurs between the extractant RC8 (Juang and Chen 1997), and the hydroxyl-Methylene blue intermediate complex formed. In contrast, the extraction favors a pH value of 11 because of the higher groups of polar species present. The MB-RC8 carrier complex is transported through the membrane from the source to the receiving phase, and the counter-ion is transported in the opposite direction. It was found that MB transport increases with the increase in the pH of the aqueous source phase up to 11.0. Therefore, a pH gradient provides the path for transport of methylene blue.

PIM stability and reusability evaluation

The stability of PIM gives it a definite advantage compared to other liquid membranes. In order to study the stability and the reusability of the PIM experiments were carried out as indicated in Fig. 10. The PIM was used five times in the removal of methylene blue dye. Each time it has been used. The elimination rate decreased by 11% (72.55–64.33%) after five cycles of use, which shows that PIM has excellent regeneration and reusability. Indeed, the membrane with the calix [4]resorcinarene derivative shows remarkable transport flux. Likewise PIM keeps the same properties.

% removal of MB in consecutive transport experiments preferment on the same membrane; Feed phase: MB 100 mg/L, pH 11. Stripping phase: 0.3 M HCl. Membrane: RC8:0.05 g/g base polymer + 0.4 mL (2-NPOE)/g base polymers. Values obtained after 30 h of experimentation. %RSD in parentheses, stirring rate 600 rpm, T 25 °C

Transport mechanism

MB is a cationic dye as indicated by its structural formula (Fig. 1). The dye cation in the feed phase is diffused through the membrane liquid PIM containing the calix[4]resorcinarene. The proposed transport mechanism of the target can be presented by a cycle with the following steps. At the basics medium of the feed phase, the dye remains unionized. Dye molecules were also complexed by the carrier and then diffused into the liquid organic phase to the acidic strip phase, the unionized dye molecules were also ionized owing to the low pH. The dye is detached in the stripping phase and the carrier RC8 diffuses back to repeat the cycle (Fig. 11).

Conclusions

We have successfully applying developed inclusion polymer membranes based on CTA as a base polymer, and Calix[4] resorcinarene as a complexing agent to recover of Methylene blue from aqueous solution. Kinetic parameters of the transport between PIM and methylene blue were investigated. Experimental results showed that the percentage of removal increased with increasing methylene blue concentration. It was also observed that the flux increased with the increase in the pH values from 3 to 11. It was also seen that the content of the carrier and plasticizer in the membrane had a significant impact on the property of PIMs. The transport of dye was in line with the first-order kinetics equation. The highest flux value "8.88 × 10–7 mol m−2 s−1" was obtained with a calix[4]resorcinarene as a carrier in polymer inclusion membrane at pH 11 in the feed and 0.3 M HCl in the stripping solution when MB initial concentration was 100 mg/L. The membrane showed good stability under optimum conditions and maximum transport was achieved in 30 h of permeation time. It was shown that the obtained membrane separated methylene blue easily and spontaneously from the wastewater.

References

Ashraf MW (2016) Removal of methylene blue dye from wastewaters by using supported liquid membrane technology. Pol J Chem Technol 18:26–30

Benosmane N, Boutemeur B, Hamdi SM, Hamdi M (2010) Preparation, characterization and thermal studies of polymer inclusion cellulose acetate membrane with calix[4]resorcinarenes as carriers. Mater Sci Eng C 30:860

Benosmane N, Boutemeur B, Hamdi SM, Hamdi M (2015a) Removal of basic dyes from aqueous solutions using calix[4]resorcinarene carboxylic acid derivatives. J Mater Environ Sci 6(8):2277–2291

Benosmane N, Boutemeur B, Hamdi M, Hamdi SM (2015b) Application of cellulose acetate membranes for removal of toxic metal ions from aqueous solution. Fresenius Environ Bull 24:2296–2309

Benosmane N, Boutemeur B, Hamdi SM, Hamdi M (2016) The removal of phenol from synthetic wastewater using calix[4]resorcinarene derivative based polymer inclusion membrane. Algerian J Env Sc Technology 2(2):26–33

Benosmane N, Boutemeur B, Hamdi SM, Hamdi M (2018a) Citric acid removal from aqueous solution using polymer inclusion membrane based on mixture of CTA and CA. Desalin Water Treat 114:163–168

Benosmane N, Boutemeur B, Hamdi SM, Hamdi M (2018) Removal of phenol from aqueous solution using polymer inclusion membrane based on mixture of CTA and CA. Appl Water Sci. https://doi.org/10.1007/s13201-018-0643-8

Bizek V, Horacek J, Rerich R, Kousova K (1992) Amine extraction of hydroxycarboxylic acids. 1. Extraction of Citric Acid with 1-octanol=n-heptane solutions of trialkylamine. Ind Eng Chem Res 31:1554–1562

Cho Y, Xu C, Cattrall RW, Kolev SD (2011) A polymer inclusion membrane for extracting thiocyanate from weakly alkaline solutions. J Membr Sci 367:85

Forgács E, Cserháti F, Oros G (2004) Removal of synthetic dyes from wastewaters: a review. Environ Int 30:953–971

Ghoreyshi AA, Farhadpour FA, Soltanieh M, Abdelghani M (2003) Transport of small polar molecules across nonporous polymeric membranes II. Shortcomings of phenomenological models of membrane transport. J Membr Sci 211:215–234

Hedidi M, Hamdi SM, Mazari T, Boutemeur B, Rabia C, Chemat F, Hamdi M (2006) Microwave-assisted synthesis of calix[4]resorcinarenes. Tetrahedron 62:5652

Juang RS, Chen LJ (1997) Transport rate of citric acid across a supported liquid membrane containing salts of tertiary amine. J Membr Sci 123:81–87

Manzak A, Tutkun O (2004) Extracion of citric acid through an emulsion liquid membrane containing aliquat 336 as carrier. Separ Sci Technol 39:2497–2512

MEYER U, (1981) Biodegradation of synthetic organic colorants. In: Leisinger T, Cook AM, Hutter R, Nuesch J (eds) Microbial degradation of xenobiotic and recalcitrant compounds, FEMS Symposium 12. Academic Press, London, pp 371–385

Muthuraman G, Palanivelu Q (2006) Transport of textile dye in vegetable oils based supported liquid membrane. Dye Pigment 70:99–104

Nghiem LD, Mornan P, Potter ID, Perera JM, Cattrall RW, Kolev SD (2006) Extraction and transport of metal ions and small organic compounds using polymer inclusion membranes (PIMs). J Membr Sci 281:7–41

SOCIETY of DYERS and COLOURISTS (1976) Colour Index, 3rd edn. Society of Dyers and Colourists, Yorkshire, UK

Sugiura M, Kawa MK, Urita S (1987) Effect of plasticizer on the carrier-mediated transport of zinc ion through cellulose triacetate membranes. Sep Sci Technol 22:2263

Venkateswaran P, Palanivelu K (2006) Recovery of phenol from aqueous solution by supported liquid membrane using vegetable oils as liquid membrane. J Hazard Mater 131:146–152

Zoollinger H (1987) Colour Chemistry-Synthesis, Properties and Application of Organic Dyes and Pigments. VCH Publishers, New York, pp 92–100

Funding

The author(s) received no specific funding for this work.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Benosmane, N., Boutemeur, B., Hamdi, S.M. et al. Removal of methylene blue dye from aqueous solutions using polymer inclusion membrane technology. Appl Water Sci 12, 104 (2022). https://doi.org/10.1007/s13201-022-01627-1

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s13201-022-01627-1