Abstract

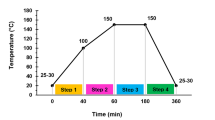

The decrease of wood supply leads to find out the alternative raw material for particleboard production derived from non-woody cellulose materials, one of the promising material is sorghum bagasse. However, the strength properties of particleboard manufactured from this biomass tend to be low. This research was to evaluate physical, mechanical and durability properties of sorghum bagasse-particleboard (SBP) which was layered by several materials. Previously, sorghum bagasse as particle board core and materials for layers such as woven of bamboo bark, woven of barkless bamboo, bamboo strand, Meranti and Eucalyptus veneer were oven dried at 103 °C to reach 4% moisture content with 10% Urea formaldehyde resin. After particle and adhesive blending step, furnish was used as core with layer materials as surface. Subsequently, mat was pressed at 130 °C for 10 min with 30 kg cm−2. Physical and mechanical properties evaluation refers to JIS A 5908-2003, while their durability properties were evaluated by grave yard test. The results showed that surface layer treatment improved the bending properties presented by increasing of modulus of rupture and modulus of elasticity value of surface layer treatment of SBP compared to untreated ones. However, their thickness swelling has not been met standard of JIS A 5908-2003 yet. Furthermore, surface layer treatment with woven of barkless bamboo showed the best physical, mechanical, and durability properties.

Similar content being viewed by others

References

Ayrilmis N, Candan Z, Hiziroglu S (2008) Physical and mechanical properties of cardboard panels made from used beverage carton with veneer overlay. Mater Des 29:1897–1903

Basri E, Saefudin (2010) Shrinkage-swelling properties and equilibrium moisture content (EMC) of bambu tali (Gigantochloa apus Kurtz) at various age and drying level. Forest Research Development Agency (FORDA), Bogor

Belayachi L, Delmas M (1995) Sweet sorghum: a quality raw material for the manufacturing of chemical pulp. Biomass Bioenergy 8(6):411–417

Choudhary R, Umagiliyage AL, Liang Y, Siddaramu T, Haddock J, Markevicius G (2012) Microwave pretreatment for enzymatic saccharification of sweet sorghum bagasse. Biomass Bioenergy 39:218–226

Fatriasari W, Hermiati E (2008) Analisis morfologi serat dan sifat fisis-kimia pada enam jenis bambu sebagai bahan baku pulp dan kertas. Jurnal Ilmu dan Teknologi Hasil Hutan 1(2):67–72

Fatriasari W, Supriyanto IA (2015) The kraft pulp and paper properties of sweet sorghum bagasse (Sorghum bicolor L Moench). J Eng Technol Sci 47(2):149–159

Geimer RL, Montrey HM, Lehmann WF (1975) Effects of layer characteristics on the properties of three-layer particleboards. For Produ J 25(9):19–29

Goshadrou A, Karimi K, Taherzadeh MJ (2011) Bioethanol production from sweet sorghum bagasse by Mucor hiemalis. Ind Crops Prod 34:1219–1225

Hadjib N, Rachman O (2010) Keteguhan lentur statis sambungan jari pada beberapa jenis kayu hutan tanaman. http://forda-mof.org

Irle M, Barbu MC (2010) Wood based panel technology. In: Thoemen H, Irle M, Šernek M (eds) Wood-based panels: an introduction for specialists. Brunel University Press, London

Iswanto AH (2014) Characterization of Jatropha curcas L fruit hulls and its utilization to produce high quality particle board. Dissertation, Bogor Agricultural University, Indonesia (In Indonesian)

Iswanto AH, Febrianto F, Wahyudi I, Hwang WJ, Lee SH, Kwon JH, Kwon SM, Kim NH, Kondo T (2010) effect of pre-treatment techniques on physical, mechanical and durability properties of oriented strand board made from sentang wood (Melia excelsa Jack). J Fac Agric Kyushu Univ 55(2):371–377

Iswanto AH, Fatriasari F, Supriyanto (2012) The utilization of sorghum stalk waste (Sorghum bicolor (L) Monech) as particleboard materials. Paper in workshop on the current status and challenges in sorghum development in Indonesia, Bogor, 25–26 Sept 2012

Iswanto AH, Azhar I, Supriyanto SA (2014) Effect of resin type, pressing temperature and time on particleboard properties made from sorghum bagasse. Agric For Fish 3(2):62–66. doi:10.11648/j.aff.20140302.12

[JSA] Japanese Standards Association (2003) Particleboards. Japanese Industrial Standard [JIS] A 5908-2003, Japan

Kelly MW (1977) Critical literature review of relationship between processing parameter and physical properties of particleboard. General technical report FPL-10. U.S. Department of agriculture forest Service and Forest Products Laboratory, University of Wisconsin

Kumar DS, Marimuthu P (2012) Sweet sorghum stalks-an alternate agro based raw material for paper making. IPPTA J 24(3):47–50

Kusumah SS, Umemura K, Yoshioka K, Miyafuji H, Kanayama K (2016) Utilization of sweet sorghum bagasse and citric acid for manufacturing of particleboard I: effects of pre-drying treatment and citric acid content on the board properties. J Ind Crops Prod 84:34–42

Langum CE (2007) Characterization of Pacific Northwest softwoods for wood composites production. Thesis, Washington State University

Maloney TM (1993) Modern particleboard and dry-process fiberboard manufacturing (updated edition). Miller Freeman, San Francisco

Norvydas V, Minelga D (2006) Strength and stiffness properties of furniture panels covered with different coatings. J Mater Sci (Medžiagotyra) 12(4):328–332

Patil JV, Chari A, Rao SV, Mathur RM, Vimelesh B, Lal PS (2011) High bio-mass sorghum (Sorghum bicolor): an alternate raw material for pulp and paper making in India. IPPTA J 23(2):161–165

Samad MS, Burhanudin V, Wardani L (2005) Buku ajar perekat dan perekatan kayu. Fakultas Kehutanan Unlam, Banjarbaru

Sornnuwat Y, Vongkaluang C, Yoshimura T, Tsunoda K, Takahashi M (1995) Tunneling of subterranean termites, Coptotermes gestroi Wasmann and Coptotermes formosanus Shiraki, into gravel physical barriers. Jpn J Environ Entomol Zool 7:13–19

Subiyanto B, Rasyid E, Gopar M, Firmanti A (2008) Veneer and thin plywood overlaid for quality improvement of particleboard made of palm oil empty fruit bunches (EFB). J Trop Wood Sci Technol 6(1):17–20

Suhasman MMY, Hadi YS (2005) The quality of composite board made from sengon wood wastes and recycled carton. J Perenn 2(1):6–11

Sulistyowati AC (1997) Pengawetan Bambu. WACANA No. 6/Januari-Pebruari 1997

Supriyanto, Iswanto AH, Fatriasari W (2012) Production of liquid organic fertilizer, particle board and kraft paper derived from sweet sorghum. Res Propos DIPA Biotrop for funding years of 2012 (unpublish)

Suryaningsih R, Irhas (2014) Bioenergy plants In Indonesia: sorghum for producing bioethanol as an alternative energy substitute of fossil fuels. Energy Proced 47:211–216

Sutigno P (2000) Perekat dan Perekatan. Forest Research Development Agency, Bogor

Vernois MM (2007) Heat treatment of wood in France-state of the art. Centre Technique du Bois et de I’ Ameublement, Paris, p 6

Wang W, Zhuang X, Yuan Z, Yu Q, Qi W, Wang Q, Tan X (2012) High consistency enzymatic saccharification of sweet sorghum bagasse pretreated with liquid hot water. Bioresour Technol 108:252–257

Youngquist JA (1999) Wood-based composites and panel products. Wood Hand Book: Wood as an Engineering Material, Washington, DC

Acknowledgements

We would like to express my sincerely thanks to Directorate General Higher Education-Ministry of Research, Technology and Higher Education-Republic of Indonesia for funding support through to the Competitive Research Grant with award No. 16/UN5.2.3.1/KEU/SP/2014.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Iswanto, A.H., Aritonang, W., Azhar, I. et al. The physical, mechanical and durability properties of sorghum bagasse particleboard by layering surface treatment. J Indian Acad Wood Sci 14, 1–8 (2017). https://doi.org/10.1007/s13196-016-0181-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13196-016-0181-7