Abstract

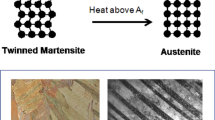

The influence of thermal processing and mechanical alloying of powder particles on the dynamic behavior and microstructural changes occurring in an Fel4Mn6Si9Cr5Ni (mass%) alloy is investigated. Five batches of 66Fe-14Mn-6Si-9Cr-5Ni (mass%) powder mixtures were produced via powder metallurgy. After powder mixing, different volume fractions (from 0 to 40 vol%) were mechanically alloyed, remixed with the rest of as-blended particles, compressed, sintered and subsequently hot rolled to a thickness of 1 mm. They were then subjected to a thermal treatment (annealing) at different temperatures and subsequently quenched into water. Thus, we had 25 different specimens for experimentation. The specimens were then machined and loaded in tension and subjected to dynamic mechanical analysis (DMA) by varying the temperature and strain amplitude. In the DMA tests, the samples were cycled between the ambient temperature and 673 K keeping the amplitude constant, while varying the temperature. These results were then correlated to the thermomagnetic properties that were measured in the same range of temperatures. Based on these data, the internal friction (tan δ) maxima, correlated with storage modulus (E′) discontinuities, were associated with the multistage reverse transformations of martensite (ε, hcp) to austenite, superimposed over the antiferromagnetic–paramagnetic transitions and accompanied by magnetization peaks (Neel temperature). The temperature ranges pertaining to tan δ maxima, E′ discontinuities and magnetization peaks were determined and discussed in terms of thermal processing temperature and volume fraction of mechanically alloyed powder particles. The variation of storage modulus with strain for three different cycles (with strain amplitude varying from zero to maximum) was traced for three different temperatures: (i) T = RT; (ii) T < Ttanδ (max); (iii) T > Ttanδ (max). The role of magnitude of thermal treatment temperature and volume fraction of mechanically alloyed powder particles on the storage modulus plateaus were given prominence for these temperatures (RT, below tanδmax and above tanδmax) as they influence the evolution of the microstructure.

Similar content being viewed by others

References

Sato A, Chishima E, Soma K, and Mori T, Acta Metall 30 (1982) 1177.

Murakami M, Suzuki H, and Nakamura Y, Trans ISIJ 27 (1987) B-87.

Otsuka H, Yamada H, Maruyama T, Matsuda S and Murakami M, ISIJInt 30(1990) 674.

Moriya Y, Kimura H, lshizaki S, Hashizume S, Suzuki S, Suzuki H and Sampei T, J Phys IV France 01 (1991) C4433.

Otsuka H, MRS Proceedings 246 (1991) doi: 10. 1557/PROC: 246–309.

Bujoreanu L G, Dia V, Stanciu S, Susan M and Baciu C, EurPhys J-ST 158 (2008) 15.

Druker A V, Perotti A, Esquivel I and Malarria J, Mater Design 56 (2014)878.

Maruyama T, Kurita T, Kozaki S, Andou K, Farjami S and Kubo H,Mater Sci Technol 24 (2008)908.

Sawaguchi T, Kikuchi T, Ogawa K, Kajiwara S, lkeo Y, Kojima M and Ogawa T, Mater Trans 47 (2006)580.

Shahverdi M, Czaderski C and Motavalli M, Constr Build Mater 112 (2016)25.

Sawaguchi T, Maruyama T, Otsuka H, Kushibe A, lnoue Y and Tsuzaki K, Mater Trans 57 (2016)283.

Torra V, lsalgue A, Lovey F C and Sade M , J Therm Anal Calorim 119 (2015) 1475.

Sawaguchi T, Bujoreanu L G, Kikuchi T, Ogawa K, Koyama M and Murakami M, Scripta Mater 59 (2008) 826.

Kajiwara S, Mater Sci Eng A 273-275 (1999)67.

Arruda G J, Buono V T L and Andrade M S, Mater Sci Eng A 273-275 (1999) 528.

Bracke L, Mertens G, Penning J, De Cooman B C, Liebeherr M andAkdut N, Metall Mater Trans A 37A (2006) 307.

Berns H and Theisen W, Ferrous Materials. Steel and Cast Iron, Springer (2008) p190, p 378, p 397.

Suzuki Y, in Shape memory materials, (eds.) Otsuka K and Wayman C M, Cambridge University Press (1998) p133.

Liu T, Liu H Y, Zhao Z T, Ma R Z, Hu T D, and Xie Y N , Mater Sci EngA 271(1999) 8.

Zhang Z, Sandstrom R, Frisk K and Salwen A, Powder Technol 137 (2003)139.

Dogan A and Arslan H, J Therm Anal Colarim 109 (2012)933.

Amini R, Shamsipoor A, Ghaffari M, Alizadeh M and Okyay A K, Mater Charact 84 (2013)169.

Saito T, Kapusta C and Takasaki A, Mat Sci Eng A. 592(2014)88.

Dang S, Li Y G, Zou Q, Wang M Z, Jiong J C, and Luo W Q, J MatEng,47 (2019) 18.

Bujoreanu L G, Stanciu S, Ozkal B, ComaneciR I and Meyer M, Proc. ESCOMAT, 2009 05003.

Pricop B, Soyler U, Comaneci RI, Ozkal B and Bujoreanu LG, PhysProceed 10 (2010)125.

Pricop B, Soyler U, Ozkal B, Lohan N M, Paraschiv A L, Suru M G and Bujoreanu L G, Mater Sci Forum 738-739 (2013)237.

Pricop B, Soyler U, Ozkal B, Lohan N M, Comaneci R I, Cimpoesu N, Musat V, Gurau G, Istrate B, Mihalache E and Bujoreanu L G, Mater Today: Proc2 (2015)S789.

Pricop B, Soyler U, Lohan N M, Ozkal B, Chicet D, David A and Bujoreanu LG,Optoelectron Adv Mater 5 (2011) 555.

Pricop B, Soyler U, Lohan N M, Ozkal B, Bujoreanu LG,Chicet D, David A and Munteanu C, J Mater Eng Perfom 21 (2012)2407.

Pricop B, Ozkal B, Soyler U, Van Humbeeck J, Lohan N M, Suru M G and Bujoreanu LG, Optoelectron Adv Mater 8 (2014)247.

Soyler A U, Ozkal B, Bujoreanu L G, J Mater Eng Perform 23 (2014)2357.

Pricop B, Mihalache E, Lohan N M, Istrate B, Mocanu M, Ozkal B, and Bujoreanu LG,MATEC Web Conf 33 (2015)04004.

Pricop B, Mihalache E, Stoian G, Borza F, Ozkal B and Bujoreanu L G, Powder Met 61 (2018)348.

Soyler A U, Ozkal B and Bujoreanu L G, TMS Suppl. Proc. Vol. 1(2011)577.

de Oro Calderon R, Gierl-Mayor C and Danninger H, J Therm Anal Colarim 127 (2017) 91.

Bowman H A and Schoonover R M, J Res Natl Inst Stan-C Eng Instr 71 (1967)179.

Druker A, Baruj A and Malarria J, Mater Char 61 (2010)603.

Spiridon I P, Lohan N M , Suru M G, Mihalache E, Bujoreanu L G and Pricop B, Met Sci Heat Treat, 2016; 57(9-10): 548-552.

Bujoreanu L G, Electronic Supplementary Data. Online Figshare, 2019 https://bit.ly/2skO6IW

Sawaguchi T, Bujoreanu L G, Kikuchi T, Ogawa K and Yin F, ISIJ Inter 48 (2008)99.

Mihalache E, Pricop B, Suru M G, Lohan N M, Comaneci R I, Istrate B, Ozkal B and Bujoreanu L G, MATEC Web Conf 33 (2015)04002.

Mocanu M, Mihalache E, Pricop B, Borza F, Grigoras M, Comaneci R I, Ozkal B, and Bujoreanu L G, in: Proc ICMAT Chicago, (eds.) Stebner A P and Olson G B, The Minerals, Metals and Materials Series (2018) p99.

Wang L, Cui Y G, Wan J F, Zhang J H and Rong Y H, AIP Adv 3(2013)082126.

Suru M G, Lohan N M, Mihalache E, Pricop B, Mocanu M and Bujoreanu L G, J Test Eval 45 (2017)419.

Chen S, Chung C Y, Yan C and Hsu T Y, Mater Sci Eng A264 (1999)262.

Wan J F, Chen S P, Hsu T Y, Huang Y N, Mater Sci Eng A 438-440 (2006)887.

Qin X Y, Yu M P, Zhang Y S, J Mater Sci 31 (1996)2311.

Lu X, Qin Z, Zhang Y, Wang X, Li F, Ding B and Hu Z, J Mater Sci 35 (2000)5597.

Gavriljuk V G, Yakovenko P G and Ullakko K, Scripta Mater 38 (1998)931.

Dong Z, Sawaguchi T, Kikuchi T, Yin F, Ogawa K, Sahu P, and KajiwaraS, Mater Sci Eng A 442 (2006) 404.

Zhou Z C, Mater Sci Eng A 438-440 (2006) 336.

Bouaziz O, Allain S, Scott C P, Cugy P, and Barbier D, Curr Opin Solid St M15 (2011) 141.

Stanford N E and Dunne D PISIJ Inter 46 (2006)1703.

Chen J, Peng H B, Yang Q, Wang S L, Song F and Wen Y H, Mater Sci EngA 677 (2016) 133.

King H W and Peters M A Can Metall Quart 36 (1997)137.

Guerrero L M, La Roca P, Malamud F, Baruj A, Sade M, Mater Design 116 (2017)127.

Fuster V, Druker A V, Baruj A, Malarria J, Bolmaro R, Mater Char 109 (2015)128.

Malamud F, Castro F, Guerrero L M, La Roca P, Sade M, Baruj A, JAppl Crystall 53 (2020) doi.org/https://doi.org/10.1107/S1600576719015024.

Verbeken K, Van Caenegem N, Verhaege M, Maer Sci Eng A 481-482 (2008)471.

Akhondzadeh A, Zangeneh-Madar K, Abbasi S M, Mater Sci Eng A 489 (2008)267.

Pricop B, Söyler AU, Özkal B, Bujoreanu LG, Front. Mater. 7(2020)247 doi: https://doi.org/10.3389/fmats.2020.00247.

Acknowledgements

SEM micrographs were recorded with the valuable help of Prof. N. Cimpoesu. The expert contribution of Prof. V. Sampath in text editing is gratefully acknowledged.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Pricop, B., Borza, F., Ozkal, B. et al. Influence of Thermal and Mechanical/Powder Processing on Microstructure and Dynamic Stiffness of Fe-Mn-Si-Cr-Ni Shape Memory Alloy. Trans Indian Inst Met 74, 1409–1418 (2021). https://doi.org/10.1007/s12666-021-02215-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12666-021-02215-8