Abstract

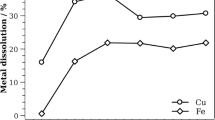

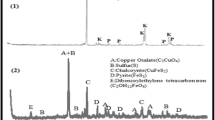

This study is concerned with the leaching process of copper with hydrogen peroxide (H2O2) and formic acid (HCOOH) from the Küre chalcopyrite concentrate. All experiments were carried out in a leaching system equipped with an adjustable temperature shaker under atmospheric pressure. The needed oxygen was provided by H2O2 decomposition to achieve the oxidizing leaching medium. The parameters affecting leaching process, H2O2 concentration, HCOOH concentration, sulfuric acid (H2SO4) concentration, leaching time, liquid/solid ratio and stirring speed, were studied. The optimum experimental conditions were determined as leaching temperature 40 °C, leaching time 120 min, H2O2 concentration 1.2 M, HCOOH concentration 3 M and stirring speed 500 rpm. It was observed that there was no positive effect of sulfuric acid (H2SO4) concentration on the metal extraction. In addition, the percentage of copper passing to solution was increased from 7.83 to 62.37% as a result of the liquid/solid ratio increasing from 2.0 to 100, respectively. Consequently, formic acid could be used as an alternative and organic leaching agent in the selective leaching of chalcopyrite and even for leaching processes of the other oxidized and sulfured ores containing precious metals.

Graphic Abstract

Similar content being viewed by others

References

Davenport W G, King M J, Schlesinger M E, and Biswas A K, Extractive Metallurgy of Copper, Elsevier, Amsterdam (2002).

Zhao H, Hu M, Li Y, Shan Z H U, Qin W, Qiu G, and Jun W, Trans Nonferrous Met Soc China25 (2015) 303.

Deng J, Wen S, Yin Q, Wu D, and Sun Q, J Taiwan Inst Chem Eng71 (2017) 20. https://doi.org/10.1016/j.jtice.2016.11.013.

Bogdanović G D, Stanković V D, Trumić M S, Antić D V, and Trumić M Ž, J Min Metall A Min52 (2016) 45.

Arzutug M E, Kocakerim M M, and Çopur M, Ind Eng Chem Res43 (2004) 4118.

Künkül A, Gülezgin A, and Demirkiran N, Chem Ind Chem Eng Q19 (2013) 25. https://doi.org/10.2298/ciceq120113039k.

Muchez P, and Corbella M, J Geochem Explor118 (2012) 38. https://doi.org/10.1016/j.gexplo.2012.04.006.

Córdoba E M, Muñoz J A, Blázquez M L, González F, and Ballester A, Hydrometallurgy93 (2008) 81.

Dreisinger D, Hydrometallurgy83 (2006) 10.

Qiu T-S, Nie G-H, Wang J-F, and Cui L-F, Trans Nonferrous Met Soc China17 (2007) 418.

Pan H, Yang H, Tong L, Zhong C, and Zhao Y, Trans Nonferrous Met Soc China22 (2012) 2255.

Antonijević M M, and Bogdanović G D, Hydrometallurgy73 (2004) 245.

Klauber C, Int J Miner Process86 (2008) 1.

Rodrıguez Y, Ballester A, Blazquez M L, Gonzalez F, and Munoz J A, Hydrometallurgy71 (2003) 47.

McDonald R G, and Muir D M, Hydrometallurgy86 (2007) 191.

Khoshkhoo M, Dopson M, Engström F, and Sandström Å, Miner Eng100 (2017) 9.

Córdoba E M, Muñoz J A, Blázquez M L, González F, and Ballester A, Hydrometallurgy93 (2008) 106.

Watling H R, Hydrometallurgy140 (2013) 163.

Kinnunen P H, and Puhakka J A, J Chem Technol Biotechnol Int Res Process Environ Clean Technol 79 (2004) 830.

Sokić M, Marković B, Stanković S, Kamberović Ž, Štrbac N, Manojlović V, and Petronijević N, Metals9 (2019) 1.

Y J Xian, S M Wen, J S Deng, J Liu, and Q Nie, Can Metall Q51 (2012) 133.

Nabizadeh A, and Aghazadeh V, Hydrometallurgy152 (2015) 61.

Watling H R, Hydrometallurgy146 (2014) 96.

Dutrizac J E, Hydrometallurgy23 (1990) 153.

Turkmen Y, and Kaya E, J Ore Dress11 (2009) 16.

Nicol M, Miki H, and Velásquez-Yévenes L, Hydrometallurgy103 (2010) 86.

Ahn J, Wu J, and Lee J, Hydrometallurgy187 (2019) 54.

B C Tanda, J J Eksteen, E A Oraby, and G M O’Connor, Miner Eng135 (2019) 118.

Larba R, Boukerche I, Alane N, Habbache N, Djerad S, and Tifouti L, Hydrometallurgy134–135 (2013) 117. https://doi.org/10.1016/j.hydromet.2013.02.002.

Ghasemi S M S, and Azizi A, J Min Environ8 (2016) 12. https://doi.org/10.22044/jme.2016.767.

Havlik T, and Skrobian M, Can Metall Q29 (1990) 133.

J Wu, J Ahn, and J Lee, Korean J Met Mater57 (2019) 245.

M M Antonijević, Z Janković, and M Dimitrijević, Hydrometallurgy35 (1994) 187.

T Agacayak, A Aras, S Aydogan, and M Erdemoglu, Physicochem Probl Miner Process50 (2014) 657.

Turan M D, and Altundoğan H S, Metall Mater Trans B44 (2013) 809.

Ruiz-Sánchez Á, and Lapidus G T, Hydrometallurgy169 (2017) 192.

Hu J, Tian G, Zi F, and Hu X, Hydrometallurgy169 (2017) 1.

Adebayo A O, Ipinmoroti K O, and Ajayi O O, Chem Biochem Eng Q17 (2003) 213.

Turan M D, Sari Z A, and Miller J D, Trans Nonferrous Met Soc China27 (2017) 1404.

Mahajan V, Misra M, Zhong K, and Fuerstenau M C, Miner Eng20 (2007) 670.

Petrovic S J, Bogdanovic G D, and Antonijevic M M, Trans Nonferrous Met Soc China28 (2018) 1444.

Mendham J, Vogels Textbook of Quantitative Chemical Analysis, Pearson Education India, Bengaluru (2006).

Olubambi P A, and Potgieter J H, Min Process Ext Met Rev30 (2009) 327.

Misra M, and Fuerstenau M C, Min Eng18 (2005) 293.

Solis-Marcial O J, and Lapidus G T, Hydrometallurgy131 (2013) 120.

Arslanoğlu H, and Yaraş A, Petrol Sci Technol37 (2019) 2081.

Yaraş A, and Arslanoğlu H, Can Metall Q57 (2018) 319.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Arslanoğlu, H., Yaraş, A. Chalcopyrite Leaching with Hydrogen Peroxide in Formic Acid Medium. Trans Indian Inst Met 73, 785–792 (2020). https://doi.org/10.1007/s12666-020-01896-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12666-020-01896-x