Abstract

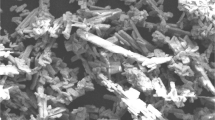

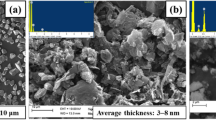

Present work aims to develop Al composite reinforced by intermetallic particles. Such composites provide good wear resistance along with less harm to the counterpart in comparison with ceramic-reinforced composites and thereby performance of tribosystem is improved. In the present research work, intermetallic reinforcement molybdenum disilicide (MoSi2) has been used for making Al composites having different particle contents (2, 3, 4 and 5 wt%). The composites were synthesized by stir casting process and characterized by SEM and XRD. Dry sliding wear tests were carried out in a pin-on-disc wear testing machine at different applied loads of 30 N, 60 N and 90 N. Effects of particle content, applied load and sliding distance on density, hardness, volume loss, wear rate and mode of material removal/wear mechanisms have been analysed critically. It has been found that with increase in applied load, mode of material removal changes as ploughing, delamination, crater formation and plastically deformed layers. Particle content and frictional heating affect the wear characteristics. With increase in applied load, performance (wear resistance) of composite has been found to be improved when compared with that of the monolith.

Similar content being viewed by others

References

Bekheet N E, Gadelrab R M, Salah M F, and Abd-El-Azim A N, Maert Des23 (2002) 153.

Balasivanandha P S, Karunamoorthy L, Kathiresan S, and Mohan B, J Maert Process Tech171 (2006) 268.

Rao R N, Das S, Mondal D P, and Dixit G, Trib Int43 (2010) 330.

Balaji V, Sateeshb N, and Hussain M M, Maert Today Proc2 (2015) 3403.

Siddhalingeshwar I G, Behera A, Mitra R, and Chakraborty M, Trans Ind Inst Met62 (2009) 379.

Gao Q, Shusen W, Shulin L, Duan X, and Ping A, Maert Des94 (2016) 79.

Kok M, J Mater Pro Tech161 (2005) 381.

Hashim J, Looney L, and Hashmi M S J, J Mat Pro Tech119 (2001) 324.

Tavoosi M, Karimzadeh F, Enayati M H, and Heidarpour A, J Alloy Comp475 (2009) 198.

Sekar K, Allesu K, and Joseph M A, Trans Ind Inst Met68 (2015) S115.

Baradeswaran A, and Perumal E A, Comp56 (2014) 464.

Baradeswaran A, and Perumal E A, Comp56 (2014) 472.

Corrochano J, Lieblich M, and Ibanez J, Comp Part A42 (2011) 1093.

Torres B, Lieblich M, Ibanez J, and Garcıa-Escorial A, Scripta Mater47 (2002) 45.

Corrochano J, Lieblich M, and Ibanez Comp Sci Tech69 (2009) 1818.

Wang Y, Rainforth W M, Jones H, and Lieblich M, Wear251 (2001) 1421.

Walker J C, Rainforth W M, and Jones H, Wear259 (2005) 577.

Sameezadeh M, Emamy M, and Farhangi H, Mater Des32 (2011) 2157.

Walker J C, Ross I M, Rainforth W M, and Lieblich M, Wear263 (2007) 707.

Corrochano J, Walker J C, Lieblich M, Ibanez J, and Rainforth W M, Wear270 (2011) 658.

V Gousia, A Tsioukis, A Lekatou, and Karantzalis A E, JMEPEG, 25 (2016) 3107.

Uvaraja1 V C, and Natarajan N, J Min Mater Cha Eng., 11–8 (2012) 757.

Sahu M K, and Sahu R K, J Trans Ind Inst Met70 (2017) 2563.

Reiso O, Overlie H G, and Ryum N, J of Metall Trans A21 (1990) 1689.

Tyagi R, Nath S K, and Ray S, Met Mat Tra A33A (2002) 3479.

Kumar N, Gautam G, Gautam R K, Mohan A, and Mohan S, Tribo139 (2017) 011601.

S Hassan, Ostovan K, Tayebi M, and Rajaeed R, Tribo Inter116 (2017) 244.

Kumar S, Pandey R, Panwar R S, and Pandey O P, Mater Eng Per, 11 (2013) 3350.

Kumar R, and Dhiman S, Mat Des50 (2013) 351.

Siddesh K N G, Ram P T, Mishra R K, Eswaraprasad N, Shiva S G S, and Basavarajappa S, Measurments128 (2018) 362.

Gautam G, Kumar N, Mohan A, Gautam R K, and Mohan S, Metall Mat Trans47A (2016) 4709.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Manoj, M.K., Gadpale, V. Synthesis, Characterization and Dry Sliding Wear Behaviour of Al 7075–MoSi2 Composites Prepared by Stir Casting Technique. Trans Indian Inst Met 72, 3153–3169 (2019). https://doi.org/10.1007/s12666-019-01781-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12666-019-01781-2