Abstract

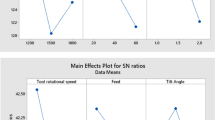

In this study, a novel friction stir extrusion (FSE) process is investigated for fabrication of fully-consolidated wires. The process parameters of rotational speed (RS), plunge rate (PR), and extrusion hole size are optimized using the Taguchi L8 orthogonal design of experiments. The optimum process parameters are determined with reference to the average grain size of the wire. The analysis of variance shows that the RS of plunge die is the most dominant factor in deciding the soundness of joint, while PR also plays a significant role. The microstructural studies reveal that initial grains of Mg ingot undergoes significant refinement in the specimens produced by the FSE process. Mechanical tests show that almost all recycled specimens can achieve higher strength and elongation than parent material at room temperature. This study shows that defect free, high quality wires can be produced using a proper combination of process parameters and recommends parameters for producing the best wire properties.

Similar content being viewed by others

References

Nakanishi M, Mabuchi M, Saito N, Nakamura M, and K. Higashi, J Mater Sci Lett 17 (1998) 2003.

Chino Y, and Hoshika T, Mabuchi M, Mater Sci Eng A, 435 (2006) 275.

Peng T, Wang Q, and Lin J, Mater Sci Eng A 516 (2009) 23.

Hu M, Ji Z, Chen X, Wang Q, and Ding W, Trans Nonferrous Met Soc China 22 (2012) s68.

Zhang T, Ji Z and Wu S, Mater Des 32 (2011) 2742.

Shanthi M, Lim C, and Lu L, Tribol Int 40 (2007) 335.

Ji Z, Wen L, and Li X, J Mater Process Technol 209 (2009) 2128.

Chino Y, Kishihara R, Shimojima K, Hosokawa H, Yamada Y, Wen CE, Iwasaki H, and Mabuchi M, Mater Trans 43 (2002)2437.

Wu S, Ji Z, and Zhang T, J Mater Process Technol 209 (2009) 5319.

Thomas W M, Nicholas E D, and Jones SB, Friction extrusion, metal working, US Patent # 5,262,123. Application No. 9125978.9, 1991 (1993).

Mishra R S, and Ma Z, Mater Sci Eng: R: Rep 50 (2005) 1.

Pellegrino J, Margolis N, Justiniano M, Miller M and Thedki A, Energ, Inc E3M 169 (2004).

Das S K, Green J A, Kaufman J G, Emadi D, and Mahfoud M, JOM 62 (2010) 23.

Tang W, and Reynolds A, J Mater Process Technol 210 (2010) 2231.

Behnagh R A, Mahdavinejad R, Yavari A, Abdollahi M, and Narvan M, Metall Mater Trans B (2014) 1.

Jayaraman M, Sivasubramanian R, and Balasubramanian V, J Mater Sci Technol 25 (2009) 655.

Ghosh M, Kumar K, Kailas S, and Ray A K, Mater Des 31 (2010). 3033.

Lakshminarayanan A, and Balasubramanian V, Trans Nonferrous Metals Soc China 18 (2008) 548.

Akbarzadeh A, Kouravand S, and Imani B M, J Optim Theory Appl 157 (2013) 188.

Sathiya P, Jaleel M A, Katherasan D, and Shanmugarajan B, Opt Laser Technol 43 (2011) 660.

Bilici M K, Yükler A İ, and Kurtulmuş M, Mater Des 32 (2011) 4074.

Yin Y, Ikuta A, and North T, Mater Des 31 (2010) 4764.

U. G. A. G. I. Taguchijeve, V -T P FSW, Application of grey relation analysis (GRA) and Taguchi method for the parametric optimization of friction stir welding (FSW) process, Mater Tehnol 44 (2010) 205.

Bozkurt Y, Mater Des 35 (2012) 440.

Lin T -R, J Mater Process Technol 127 (2002) 1.

ASTM Standard #E407-07, Standard test methods for microetching, 2004.

ASTM Standard #E3-11, Standard test methods for Sample grounding and polishing, 2004.

ASTM Standard #E8M-E384-11, Standard test methods for determining average grainsize 2004.

ASTM Standard #E290-92, Standard test method for bend testing of Material for ductility 2009.

Asadi P, Besharati Givi M K, and Faraji G, Mater Manuf Process 25 (2010) 1219.

Commin L, Dumont M, Masse J E, and Barrallier L, Acta Mater 57 (2009) 326.

Scialpi A, Mater Des 28 (2007) 1124.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Ansari, M.A., Behnagh, R.A., Narvan, M. et al. Optimization of Friction Stir Extrusion (FSE) Parameters Through Taguchi Technique. Trans Indian Inst Met 69, 1351–1357 (2016). https://doi.org/10.1007/s12666-015-0686-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12666-015-0686-6