Abstract

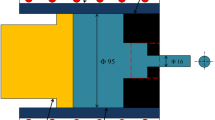

An advanced rheomolder, equipped with a thin-walled phone cover mold, was introduced and used to manufacture the AZ91D magnesium alloy. Effects of different processing parameters including pouring temperature, cylinder temperature and injection velocity on the microstructure and mechanical properties were investigated. The results showed that, with the decrease of pouring temperature or the increase of injection velocity, the size of α 1 -Mg decreases while the sphericity increases, and the porosity fraction reduces, which raise mechanical properties of rheomolded AZ91D. As the cylinder temperature decreases, the size of α 1 -Mg decreases and the sphericity increases initially and then remains relatively unchanged while the solid fraction increases continuously. Also, the cylinder temperature has a significant effect on mechanical properties of rheomolded AZ91D and the highest mechanical property is obtained at a cylinder temperature of 555 °C. The optimal rheomolded AZ91D with tensile strength of 273 MPa and elongation of 7.2 % were obtained at the pouring temperature of 600 °C, injection velocity of 2.1 m/s and cylinder temperature of 555 °C. Compared with high pressure die-casting, the tensile strength and elongation were increased by 22.4 and 213 %, respectively.

Similar content being viewed by others

References

Jiang J F, Wang Y, Li Y F, Shan W W, and Luo S J, Mater Des, 37 (2012) 202.

Boby A, Pillai U T S, and Pai B C, Trans Indian Inst Met, 66 (2013) 105.

Tzamtzis S, Zhang H, Xia M, Hari Babu N, and Fan Z, Mater Sci Eng A, 528 (2011) 2664.

Matsumoto R, Trans Nonferrous Met Soc China, 20 (2010) 1275.

Zhao Z D, Chen Q, Chao H Y, and Huang S H, Mater Des, 3 (2010) 1906.

Jiang J F, Wang Y, Chen G, Liu J, Li Y S, and Luo S J, Mater Des, 40 (2012) 541.

Polmear L J, Mater Trans, 37 (1996) 12.

Yang L Q, Kang Y L, Zhang F, and Xu J, Trans Nonferrous Met Soc China, 20 (2010) 862.

Flemings M C, Metal Trans A, 22 (1991) 957.

Czerwinski F, Metall Mater Trans A, 33 (2002) 2963.

Zhang Y F, Liu Y B, and Cao Z Y, J Mater Process Technol, 209 (2009) 1375.

Ghosh D, Kang K, and Roemer J G, in Advances in Production and Fabrication of Light Metals and Metal Matrix Composites, (eds) Avedesian M M, Larouche L J, and Masounave J, Montreal (1992), p 399.

Tsukeda T, Takeya K, and Saito K, J Japan Inst of Light Metals, 47 (1999) 287.

Czerwinski F, Acta Mater, 53 (2005) 1973.

Czerwinski F, Mater Sci Eng A, 392 (2005) 51.

Cui X P, The Research on the Microstructure and Process of Thixomolding AZ91D Magnesium Alloy, Ph D Thesis, University of Jilin, China (2006).

Fan Z T, Huang N Y, Luo J R, and Wu S S, Spec Cast Nonferrous Alloys, 2 (2001) 22.

Yang L Q, Kang Y L, and Zhang F, Trans Nonferrous Met Soc China, 20 (2010) 966.

Fan Z, Liu G, and Wang Y, J Mater Sci, 41 (2006) 3631.

Wang Y, Xia M, Fan Z, Zhou X, and Thompson G E, Intermetallics, 18 (2010) 1863.

Koren Z, Rosenson H, Gutman E M, Unigovski Y B, and Eliezer A, J Light Met, 2 (2002) 81.

Xia K, and Tausig G, Mater Sci Eng A, 246 (1998) 1.

Dong J, Cui J X, and Le Q C, Mater Sci Eng A, 345 (2003) 234.

Le Q C, Ou P, Wu Y D, Lu G M, Cui J Z, and Qiu Z X, Acta Metall Sin, 38 (2002) 219.

Czerwinski F, Zielinska-Lipiec A, and Pinet P J, Acta Mater, 49 (2001) 1225.

Patel H A, Chen D L, and Bhole S D, J Alloys Compd, 496 (2010) 140.

Galiev A M, and Kaibyshev R O, Phys Met Metall, 81 (1996) 451.

Ghosh D, Kang W, and Bach C, in Proceedings of the International Symposium on Recent Metallurgical Advances in Light metals Industries, (eds) Macewen S, and Gilardeau J P, Vancouver (1995), p 473.

Acknowledgments

The authors really appreciate the support from National Program on Key Basic Research Project of China (2011CB606302) and National High-tech R&D Program of China (2013AA031001).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Qi, M., Kang, Y., Zhou, B. et al. Effects of Processing Parameters on Microstructure and Mechanical Properties of Rheomolded AZ91D Magnesium Alloy. Trans Indian Inst Met 69, 673–682 (2016). https://doi.org/10.1007/s12666-015-0538-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12666-015-0538-4