Abstract

Coal-bed methane (CBM) hazards are among the principal hazards in a coal mine, causing events such as coal and gas outbursts, and gas explosions. CBM drainage in underground coal mines plays a fundamental role in preventing coal mine accidents and ensuring safe production in coal mines. The effective sealing of boreholes is regarded as an important measure in the guarantee of efficient CBM drainage. Aiming at the shortcomings of conventional sealants (their poor stability, low permeability, and low adaptability), a flexible gel (FG) that adapts to borehole deformation and has preferable sealing performance was developed. In this study, the development method and the effect of the application of the FG were introduced, the effect of stirring status and the ratio of FG material to water on the water retention, hydrophobicity, and permeability of the FG were investigated; the sealing mechanism of the FG was proposed and the relationship between the stirring status, the ratio of FG material to water and its sealing effect were discussed. The results reveal that: (1) the viscosity of FG increases with time at low stirring speeds (600 rpm and below) and then reaches a constant viscosity. On the other hand, at high stirring speeds (800 rpm and above), the viscosity of FG first increases, then decreases, and finally reaches a constant viscosity. (2) The FG contains many hydrophobic groups and the surface has a protective layer structure: the main mechanisms in its borehole sealing role are the borehole deformation adaptability, high permeability, preferable water retention, and hydrophobicity. (3) The higher the ratio of material to water in the FG, the lower the hydrophobicity and permeability, and the better the water retention of the FG. (4) Once sufficiently stirred, FG has the lowest permeability, and the best water retention and hydrophobicity: excessively stirred FG is the next best option, and insufficiently stirred FG has the poorest water retention and hydrophobicity, but the greatest permeability. (5) To ensure good sealing performance, sufficiently stirred FG, with a lower ratio of material to water, is selected as the sealing material.

Similar content being viewed by others

References

Chen X (2011) Mechanics of mining rock mass. China University of Mining and Technology Press, Xu Zhou

Chen X, Cheng Y (2015) Influence of the injected water on gas outburst disasters in coal mine. Nat Hazards 76:1093–1109

Cheng Y, Fu J, Yu Q (2009) Development of gas extraction technology in coal mines of China. J Min saf Eng 26:127–139

Escudier MP, Oliveira PJ, Pinho FT (2002) Fully developed laminar flow of purely viscous non-Newtonian liquids through annuli, including the effects of eccentricity and inner-cylinder rotation. Int J Heat Fluid Flow 23:52–73

Fan Y, Zhu D, Wang H (2013) New borehole sealing technology for gas drainage by double capsule device with pressure grouting. Chin J Undergr Space Eng 9:1127–1131

Flores RM (1998) Coalbed methane: from hazard to resource. Int J Coal Geol 35:3–26

Ge Z, Mei X, Lu Y (2014) Mechanical model and test study of sealed drilling for hydraulic fracturing in underground coal mines. J Basic Sci Eng 22:1128–1139

Han B, Zhang L, Jiang G (2012) Microstructure research of CMC solution at the different shearing action. Geol Sci Technol Inf 1:122–126

Hu S, Zhou F, Liu Y, Xia T (2015) Effective stress and permeability redistributions induced by successive roadway and borehole excavations. Rock Mech Rock Eng 48:319–332

Karacan CÖ, Ruiz FA, Cotè M, Phipps S (2011) Coal mine methane: a review of capture and utilization practices with benefits to mining safety and to greenhouse gas reduction. Int J Coal Geol 86:121–156

Li Q, Lin B, Zhang J (2012) Fractal characteristics of particle size distribution and its effects on the surface wetting performance of coal mine dusts. J China Coal Soc S1:138–142

Li Q, Lin B, Zhai C, Ni G, Peng S, Sun C, Cheng Y (2013) Variable frequency of pulse hydraulic fracturing for improving permeability in coal seam. Int J Min Sci Technol 23:847–853

Lin B (2010) Theory and technology of gas prevention and control in mines. China University of Mining and Technology Press, Xuzhou

Lin B, Cui H (1998) Theory and technology of gas prevention and control in mines. China University of Mining and Technology Press, Xuzhou

Lin B, Shen C (2015) Coal permeability-improving mechanism of multilevel slotting by water jet and application in coal mine gas extraction. Environ Earth Sci 73:5975–5986

Liu M (2013) Hole-sealed technology of gas drainage drilling in hydrous seam. Saf Coal Mines 3:62–63

Liu J, Ji H, He Z (2013) Study on performance and microstructure of new type sealing material suitable for freezing hole at weakly cemented soft rock. J China Coal Soc 4:595–599

Liu Q, Cheng Y, Yuan L, Fang Y, Shi D, Kong S (2014) A new effective method and new materials for high sealing performance of cross-measure CMM drainage boreholes. J Nat Gas Sci Eng 21:805–813

Liu Q, Cheng Y, Zhou H, Guo P, An F, Chen H (2015a) A mathematical model of coupled gas flow and coal deformation with gas diffusion and klinkenberg effects. Rock Mech Rock Eng 48:1163–1180

Liu Y, Wang F, Tang H, Liang S (2015b) Well type and pattern optimization method based on fine numerical simulation in coal-bed methane reservoir. Environ Earth Sci 73:5877–5890

Meng F, Jiang C, Zhao W (2010) Analysis of plugging the fracture surrounding drilling by grouting in the gas pressure measuring of coal seam. Saf Coal Min 1:87–91

Ni G, Lin B, Zhai C (2013) Microscopic properties of drilling sealing materials and their influence on the sealing performance of boreholes. J Univ Sci Technol Beijing 35:572–579

Ni G, Lin B, Zhai C, Li Q, Peng S, Li X (2014) Kinetic characteristics of coal gas desorption based on the pulsating injection. Int J Min Sci Technol 24:631–636

Park SW, Sohn IJ, Park DW, Oh KJ (2003) Absorption of carbon dioxide into non-Newtonian liquid. I. Effect of viscoelasticity. Sep Sci Technol 38:1361–1384

Sun W, Li Z, Zhou J (2012) Research on new borehole sealing material and sealing technique applied to mine gas drainage. Coal Sci Technol 4:60–63

Tongwa P, Nygaard R, Blue A, Bai B (2013) Evaluation of potential fracture-sealing materials for remediating CO2 leakage pathways during CO2 sequestration. Int J Greenh Gas Control 18:128–138

Wang W, Li X, Lin B, Zhai C (2015) Pulsating hydraulic fracturing technology in low permeability coal seams. Int J Min Sci Technol 25:681–685

Wang Z, Liu J (2005) Problems existing in methane drainage in coal mines of China and probing into the countermeasures. Saf Coal Min 36:29–32

Wei Y, Sun T, Chang Y (2013) Mechanism of sodium carboxymethyl cellulose for improving the strength of briquettes made of hematite ore and coal. J Univ Sci Technol Beijing 4:432–437

Xia T, Zhou F, Liu J, Gao F (2014) Evaluation of the pre-drained coal seam gas quality. Fuel 130:296–305

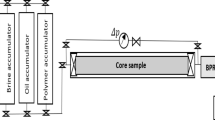

Xiang X, Zhai C, Xu Y, Yu X, Xu J (2015) A flexible gel sealing material and a novel active sealing method for coal-bed methane drainage boreholes. J Nat Gas Sci Eng 26:1187–1199

Xiao J, Xu H, Chao S (2007) Study on FN-DLC thin film: (III) hydrophobic nature analysis. Acta Phys Sin 5:2998–3003

Xie J, Liang J, Liu X (2009) Effect of the temperature on absorbency and retentive water property of PAAM super-sorbents. Polym Mater Sci Eng 25:95–97

Yang M, He Y, Chen M (2001) Law of grouting penetrating through fracture network of rock mass. J Hydraul Eng 7:41–46

Yang W, Lin B, Xu J (2014) Gas outburst affected by original rock stress direction. Nat Hazards 72:1063–1074

Zhai C, Lin B, Wang L (2008) Status and problems of drainage and utilization of downhole coalbed methane in coal mines in China. Nat Gas Ind 28:23–26

Zhai C, Li Q, Sun C (2012) Analysis on borehole instability and control method of pore- forming of hydraulic fracturing in soft coal seam. Int J Min Sci Technol 37:1431–1436

Zhai C, Xiang X, Yu X (2013) Sealing performance of flexible gel sealing material of gas drainage borehole. J China Univ Min Technol 42:982–988

Zhai C, Xu J, Xiang X, Zhong C (2015a) Flexible gel (FG) for gas-drainage drilling sealing material based on orthogonal design. Int J Min Sci Technol 25:1031–1036

Zhai C, Yu X, Xiang X, Li Q, Wu S, Xu J (2015b) Experimental study of pulsating water pressure propagation in CBM reservoirs during pulse hydraulic fracturing. J Nat Gas Sci Eng 25:15–22

Zhang C, Lin B, Zhou Y (2013a) Strong–weak–strong borehole pressurized sealing technology for horizontal gas drainage borehole in mining seam. J Min Saf Eng 30:935–939

Zhang C, Lin B, Zhou Y, Zhai C, Zhu C (2013b) Study on “fracturing–sealing” integration technology based on high-energy gas fracturing in single seam with high gas and low air permeability. Int J Min Sci Technol 23:841–846

Zhang X, Chang X, Zhang S (2013c) Heat aging mechanism FKM seal material. Lubr Eng 5:38–40

Zhou F, Li J, Ze X (2009) A study of the second hole sealing method to improve gas drainage in coal seams. J China Univ Min Technol 6:764–768

Zhou F, Wang X, Liu Y (2014) Gas drainage efficiency: an input–output model for evaluating gas drainage projects. Nat Hazards 74:989–1005

Zou Q, Lin B, Liu T, Zhou Y, Zhang Z, Yan F (2014) Variation of methane adsorption property of coal after the treatment of hydraulic slotting and methane pre-drainage: a case study. J Nat Gas Sci Eng 20:396–406

Zou Q, Lin B, Zheng C et al (2015) Novel integrated techniques of drilling–slotting–separation-sealing for enhanced coal bed methane recovery in underground coal mines. J Nat Gas Sci Eng 26:960–973

Acknowledgments

This work was financially supported by the Central Universities special Funds for Fundamental Research Funds of the China University of Mining and Technology (No. 2014ZDPY04), the National Natural Science Foundation of China (No. 51274195, U1361106), the Natural Science Foundation of Jiangsu Province (No. BK2012571), the National Major Scientific Instrument and Equipment Development Project (No. 2013YQ17046309), and the Program for New Century Excellent Talents in University (No. NCET-12-0959), the Qing Lan Project, A Project Funded by the Priority Academic Program Development of Jiangsu Higher Education Institutions (PAPD), State Key Laboratory of Coal Resources and Safe Mining, CUMT (SKLCRSM14X02).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Zhai, C., Xiang, X., Zou, Q. et al. Influence factors analysis of a flexible gel sealing material for coal-bed methane drainage boreholes. Environ Earth Sci 75, 385 (2016). https://doi.org/10.1007/s12665-016-5286-1

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s12665-016-5286-1