Abstract

This work aimed to investigate the effects of biomass species on fermentable sugar production, with respect to both energy consumption and sugar yield, using the modified traditional mechanical system from Pulp & Paper Mills as a potential biorefinery step. The study explored four lignocellulosic biomass species including corn stover, alfalfa, white birch and black spruce during the pretreatment process with and without the addition of NaOH. This was followed by a disk refining pretreatment under various operating conditions of gap size and consistency through a pilot scaled disk refining system. The study characterized and analyzed the chemical components and sugar streams obtained from the biomasses using the thermochemical and refining pretreatment and also analyzed the energy consumption of the disk refining system. The results show that for all the biomasses, the thermochemical process mainly removed lignin and hemicelluloses through a steaming pretreatment. From low to high, the lignin contents of the four biomasses are shown as follows: corn stover, alfalfa, white birch and black spruce. With respect to the refining pretreatment, when the gap size remains constant, black spruce has the longest fibers while corn stover has the shortest. Moreover, using enzymatic hydrolysis to evaluate the sugar yield revealed that the thermochemical pretreatment increased the sugar yield in accordance with how much lignin was removed from each biomass as well as their final lignin content. However, the additional refining treatment had a greater effect on corn stover and alfalfa than on white birch and black spruce due to the reduction in fiber length. Therefore, with respect to existing mechanical refining equipment, the modified thermochemical disk refining pretreatment (TCDRP) has a greater effect on agricultural biomass and hardwood (white birch). Specifically, the sugar yield of the TCDRP corn stover was the highest (97.3%) when compared to the other biomasses, while its energy consumption was 196 kWh/ton.

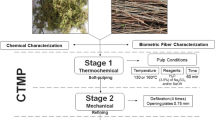

Graphic Abstract

Similar content being viewed by others

References

Tester, J.W.: Sustainable Energy: Choosing Among Options. MIT press, Cambridge (2005)

Maity, S.K.: Opportunities, recent trends and challenges of integrated biorefinery: part II. Renew. Sustain. Energy Rev. 43, 1427–1445 (2014)

Liu, S., Lu, H., Hu, R., Shupe, A., Lin, L., Liang, B.: A sustainable woody biomass biorefinery. Biotechnol. Adv. 30, 785–810 (2012)

Sousa G.D.A.: Biorefinery development pathways: a survey for the pulp and paper industry. Presented at the XXI Encontro Nacional da TECNICELPA/VI CIADICYP 2010,12-15 Outubro 2010, Lisboa, Portugal, 2010.

Morales, M., Quintero, J., Conejeros, R., Aroca, G.: Life cycle assessment of lignocellulosic bioethanol: environmental impacts and energy balance. Renew. Sustain. Energy. Rev. 42, 1349–1361 (2015)

Biermann, C.J.: Handbook of Pulping and Papermaking. California, San Diego (1996)

Rowell, R.M.: Handbook of Wood Chemistry and Wood Composites. CRC Press, Boca Raton (2005)

Berti M., Nudell R., Anfinrud R., Samarappuli D., Johnson B.: Forage resources as feedstocks for the biofuel industry in North Dakota. In: 19th European Biomass Conference and Exhibition, 2011, pp. 6–10.

Xu, L., Tschirner, U.W.: Peracetic acid pretreatment of alfalfa stem and aspen biomass. BioResources 7, 0203–0216 (2011)

Lizotte, P.L., Savoie, P., Lefsrud, M., Allard, G.: Yield and moisture content of corn stover components in Québec, Canada. Can. Biosyst. Eng. J. 56, 8.1–8.9 (2014)

Han Q.: Autohydrolysis pretreatment of lignocellulosic biomass for bioethanol production. Ph.D. Thesis, North Carolina State University (2014)

Zhu, J., Chandra, M.S., Gleisner, R., Gilles, W.T., Gao, J., Marrs, G., et al.: Case studies on sugar production from underutilized woody biomass using sulfite chemistry. TAPPI J. 14, 577–583 (2015)

Gharehkhani, S., Sadeghinezhad, E., Kazi, S.N., Yarmand, H., Badarudin, A., Safaei, M.R., et al.: Basic effects of pulp refining on fiber properties—a review. Carbohydr. Polym. 115, 785–803 (2015)

Food and Agriculture Organization of the United Nations. FAOSTAT, Ed., ed. Rome, Italy: FAOSTAT Database, 2016

Carter M.: Chetwynd Mechanical Pulp extends maintenance shut down, 2015

Van Soest, P.V., Robertson, J., Lewis, B.: Methods for dietary fiber, neutral detergent fiber, and nonstarch polysaccharides in relation to animal nutrition. J. Dairy Sci. 74, 3583–3597 (1991)

Park, J., Jones, B., Koo, B., Chen, X., Tucker, M., Yu, J.-H., et al.: Use of mechanical refining to improve the production of low-cost sugars from lignocellulosic biomass. Bioresour. Technol. 199, 59–67 (2015)

Miller, G.L.: Use of dinitrosalicylic acid reagent for determination of reducing sugar. Anal. Chem. 31, 426–428 (1959)

Li, Z., Yu, Y., Sun, J., Li, D., Huang, Y., Feng, Y.: Effect of extractives on digestibility of cellulose in corn stover with liquid hot water pretreatment. BioResources 11, 54–70 (2015)

Harmsen, P., Huijgen, W., Bermudez, L., Bakker, R.: Literature Review of Physical and Chemical Pretreatment Processes for Lignocellulosic Biomass. Wageningen, Wageningen UR, Food & Biobased Research (2010)

Pandey, A.: Biofuels: Alternative Feedstocks and Conversion Processes. Academic Press, San Diego (2011)

Luukkonen A.: Development of a methodology to optimize low consistency refining of mechanical pulp. Ph.D. Thesis, University of British Columbia (2011)

Li, B., Li, H., Zha, Q., Bandekar, R., Alsaggaf, A., Ni, Y.: Review: effects of wood quality and refining process on TMP pulp and paper quality. BioResources 6, 3569–3584 (2006)

Dundar, E., Laperrière, L., Ding, A.F.: Decreasing specific energy of thermomechanical pulps from reduction of raw materials variability. Tappi J. 8, 23–29 (2009)

Mooney, C.A., Mansfield, S.D., Beatson, R.P., Saddler, J.N.: The effect of fiber characteristics on hydrolysis and cellulase accessibility to softwood substrates. Enzyme Microb. Technol. 25, 644–650 (1999)

Zhu, J.: Physical pretreatment—woody biomass sizereduction—for forest biorefinery. Sustain. Prod. Fuels, Chem. Fibers For. Biomass 1067, 89–107 (2011)

Acknowledgements

The authors are grateful to Messrs. Alain Marchand and Bryan Brousseau for their excellent assistance. We are also sincerely thankful for the grant support from BiofuelNet. And finally, we are grateful to the sawmills and pulping mills that provided the biomasses.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Chen, J., Adjallé, K., Lai, T.T. et al. Effect of Mechanical Pretreatment for Enzymatic Hydrolysis of Woody Residues, Corn Stover and Alfalfa. Waste Biomass Valor 11, 5847–5856 (2020). https://doi.org/10.1007/s12649-019-00856-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12649-019-00856-x