Abstract

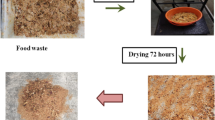

The fluidized-bed combustion (FBC) is an environmentally-friendly way to combust biomass and waste materials. However, as a side-product large amount of ash is created which is difficult to utilize due to its low reactivity and high heavy metal content. Instead, most of the ash ends up in landfills so novel utilization methods are needed. In this study lightweight aggregates (LWAs) were produced from recovered fuel-biofuel fly ash taken from a F boiler by granulating the fly ash with sodium silicate in a high-shear granulator. Blast furnace slag and metakaolin were studied as co-binders. Physical, chemical, and microstructural characterization was conducted for the precursors and LWAs. The crushing strength varied between 4.6 and 14.6 MPa. Addition of co-binders increased strength and produced denser structure. The loose bulk density was <1.08 g/cm3 and dry particle density was <1.77 g/cm3 for all prepared granules so they met the definition of lightweight aggregate in standard SFS-EN 13055-1. LWAs contained X-ray-amorphous material, indicating the formation of aluminosilicates and some crystalline phases, which were derived from the fly ash. This study presents a method of producing LWAs from fly ash that have physical properties comparable to LWAs manufactured by conventional methods without the need for high-temperature sintering or the usage of cement.

Similar content being viewed by others

References

Suomen Standardisoimisliitto SFS ry SFS-EN 450-1: Fly ash for concrete. Part 1: Definition, specifications and conformity criteria (2013)

Fernandez-Jimenez, A., Palomo, A., Macphee, D.E., Lachowski, E.E.: Fixing arsenic in alkali-activated cementitious matrices. J. Am. Ceram. Soc. 88, 1122–1126 (2005)

Guo, X., Shi, H.: Experimental analysis high-calcium fly ash geopolymers solidification/stablization of heavy metals. Tumu Jianzhu Yu Huanjing Gongcheng/J. Civ. Archit. Environ. Eng. 35, 124–128 (2013)

Komnitsas, K., Zaharaki, D., Bartzas, G.: Effect of sulphate and nitrate anions on heavy metal immobilisation in ferronickel slag geopolymers. Appl. Clay Sci. 73, 103–109 (2013)

Lancellotti, I., Kamseu, E., Michelazzi, M., Barbieri, L., Corradi, A., Leonelli, C.: Chemical stability of geopolymers containing municipal solid waste incinerator fly ash. Waste Manag 30, 673–679 (2010)

Ogundiran, M.B., Nugteren, H.W., Witkamp, G.J.: Immobilisation of lead smelting slag within spent aluminate-fly ash based geopolymers. J. Hazard. Mater. 248–249, 29–36 (2013)

Phair, J.W., van Deventer, J.S.J., Smith, J.D.: Effect of Al source and alkali activation on Pb and Cu immobilisation in fly-ash based “geopolymers”. Appl. Geochem. 19, 423–434 (2004)

Tzanakos, K., Mimilidou, A., Anastasiadou, K., Stratakis, A., Gidarakos, E.: Solidification/stabilization of ash from medical waste incineration into geopolymers. Waste Manag. 34(10), 1823–1828 (2014)

Lancellotti, I., Ponzoni, C., Bignozzi, M.C., Barbieri, L., Leonelli, C.: Incinerator bottom ash and ladle slag for geopolymers preparation. Waste Biomass Valoriz. 5, 393–401 (2014)

Ferone, C., Colangelo, F., Messina, F., Santoro, L., Cioffi, R.: Recycling of pre-washed municipal solid waste incinerator fly ash in the manufacturing of low temperature setting geopolymer materials. Materials 6, 3420–3437 (2013)

Colangelo, F., Messina, F., Cioffi, R.: Recycling of MSWI fly ash by means of cementitious double step cold bonding pelletization: technological assessment for the production of lightweight artificial aggregates. J. Hazard. Mater. 299, 181–191 (2015)

Bernal, S., Krivenko, P., Provis, J., Puertas, F., Kavalerova, E., Shi, C., van Riessen, A.: Other potential applications of alkali-activated materials. In: Provis, J.L., van Deventer, J.S.J. (eds.) Alkali Activated Materials—State-of-the Art Report, RILEM TC 224-AAM, pp. 355–360. Springer, Dordrecht (2014)

Bernal, S., Provis, J., Fernández-Jimènez, A., Krivenko, P., Kavalerova, E., Palacios, M., Shi, C.: Binder chemistry- high-calcium alkali-activated materials. In: Provis, J.L., van Deventer, J.S.J. (eds.) Alkali Activated Materials—State-of-the Art Report, RILEM TC 224-AAM, pp. 59–91. Springer, Dordrecht (2014)

Chindaprasirt, P., Rattanasak, U., Jaturapitakkul, C.: Utilization of fly ash blends from pulverized coal and fluidized bed combustions in geopolymeric materials. Cement Concrete Compos. 33, 55–60 (2011)

Chindaprasirt, P., Jenjirapanya, S., Rattanasak, U.: Characterizations of FBC/PCC fly ash geopolymeric composites. Constr. Build. Mater. 66, 72–78 (2014)

Tyni, S.K., Karppinen, J.A., Tiainen, M.S., Laitinen, R.S.: Preparation and characterization of amorphous aluminosilicate polymers from ash formed in combustion of peat and wood mixtures. J. Non Cryst. Solids 387, 94–100 (2014)

Tyni, S.K., Yliniemi, J.H., Tiainen, M.S., Laitinen, R.S.: Fly ash as precursor for geopolymers. In: Proceedings of the 21st International Conference on Fluidized Bed Combustion, vol. I, 2012, pp. 171–178 (2012)

Palomo, A., Palacios, M.: Alkali-activated cementitious materials: alternative matrices for the immobilisation of hazardous wastes: part II. Stabilisation of chromium and lead. Cement Concrete Res. 33, 289–295 (2003)

Minaríková, M., Škvara, F.: Fixation of heavy metals in geopolymeric materials based on brown coal fly Ash. Ceram. Silikáty. 50, 200–207 (2006)

Suomen Standardisoimisliitto SFS ry SFS EN 13055-1: Lightweight aggregates. Part 1: Lightweight aggregates for concrete, mortar and grout (2002)

González-Corrochano, B., Alonso-Azcárate, J., Rodas, M., Barrenechea, J.F., Luque, F.J.: Microstructure and mineralogy of lightweight aggregates manufactured from mining and industrial wastes. Constr. Build. Mater. 25, 3591–3602 (2011)

González-Corrochano, B., Alonso-Azcárate, J., Rodas, M., Luque, F.J., Barrenechea, J.F.: Microstructure and mineralogy of lightweight aggregates produced from washing aggregate sludge, fly ash and used motor oil. Cement Concrete Compos. 32, 694–707 (2010)

Ducman, V., Mladenovič, A., Šuput, J.S.: Lightweight aggregate based on waste glass and its alkali-silica reactivity. Cement Concrete Res. 32, 223–226 (2002)

Hwang, C.-L., Bui, L.A.-T., Lin, K.-L., Lo, C.-T.: Manufacture and performance of lightweight aggregate from municipal solid waste incinerator fly ash and reservoir sediment for self-consolidating lightweight concrete. Cement Concrete Compos. 34, 1159–1166 (2012)

Gesoğlu, M., Güneyisi, E., Öz, H.Ö.: Properties of lightweight aggregates produced with cold-bonding pelletization of fly ash and ground granulated blast furnace slag. Mater. Struct. 45, 1535–1546 (2012)

Arslan, H., Baykal, G.: Utilization of fly ash as engineering pellet aggregates. Environ. Geol. 50, 761–770 (2006)

Ferone, C., Colangelo, F., Messina, F., Iucolano, F., Liguori, B., Cioffi, R.: Coal combustion wastes reuse in low energy artificial aggregates manufacturing. Materials 6, 5000–5015 (2013)

Cioffi, R., Colangelo, F., Montagnaro, F., Santoro, L.: Manufacture of artificial aggregate using MSWI bottom ash. Waste Manag 31, 281–288 (2011)

Colangelo, F., Cioffi, R.: Use of cement kiln dust, blast furnace slag and marble sludge in the manufacture of sustainable artificial aggregates by means of cold bonding pelletization. Materials 6, 3139–3159 (2013)

Jo, B., Park, S., Park, J.: Properties of concrete made with alkali-activated fly ash lightweight aggregate (AFLA). Cement Concrete Compos. 29, 128–135 (2007)

Fansuri, H., Prasetyoko, D., Zhang, Z., Zhang, D.: The effect of sodium silicate and sodium hydroxide on thestrength of aggregates made from coal fly ash using the geopolymerisation method. Asia Pac. J. Chem. Eng. 7, 73–79 (2012)

Bui, L.A., Hwang, C., Chen, C., Lin, K., Hsieh, M.: Manufacture and performance of cold bonded lightweight aggregate using alkaline activators for high performance concrete. Constr. Build. Mater. 35, 1056–1062 (2012)

Yliniemi, J., Nugteren, H., Illikainen, M., Tiainen, M., Westrate, R., Niinimäki, J.: Lightweight aggregates produced by granulation of peat-wood fly ash with alkali activator. Int. J. Miner. Process. 149, 42–49 (2016)

Suomen Standardisoimisliitto SFS ry SFS-EN 15359: Solid recovered fuels. Specifications and classes (2011)

Yliniemi, J., Pesonen, J., Tiainen, M., Illikainen, M.: Alkali activation of recovered fuel-biofuel fly ash from fluidised-bed combustion: stabilisation/solidification of heavy metals. Waste Manag. 43, 273–282 (2015)

Suomen Standardisoimisliitto SFS ry SFS-EN 451-1: Method of testing fly ash. Part 1: Determination of free calcium oxide content (2004)

Suomen Standardisoimisliitto SFS ry SFS-EN 197-1: Cement. Part 1: Composition, specifications and conformity criteria for common cements (2012)

PDF-ICDD: The Powder Diffraction File, International Centre for Diffraction Data, 12 Campus Boulevard, Newtown Square, PA, USA (2006)

Suomen Standardisoimisliitto SFS ry SFS-EN 1097-3: Tests for mechanical and physical properties of aggregates. Part 3: Determination of loose bulk density and voids (1998)

Suomen Standardisoimisliitto SFS ry SFS-EN 1097-6: Tests for mechanical and physical properties of aggregates. Part 6: Determination of particle density and water absorption (2014)

Bouwman, A.: Form, formation, and deformation: the influence of material properties and process conditions on the shape of granules produced by high shear granulation. Doctoral thesis, s.n., University of Groeningen (2005)

Linkson, P., Glastonbury, J., Duffy, G.: The mechanism of granule growth in wet pelletising. Trans. Inst. Chem. Eng. 51, 251–259 (1973)

Newitt, D., Conway-Jones, J.: A contribution to the theory and practice of granulation. Trans. Inst. Chem. Eng. 36, 422–442 (1958)

Rumpf, H: The strength of granules and agglomerates. In: Knepper, W.A. (ed.) Agglomeration, pp. 379–418. Interscience publishers, New York (1962)

Dictionary of Construction: Free lime, http://www.dictionaryofconstruction.com/definition/free-lime.html

Provis, J.L., Duxson, P., van Deventer, J.S.J.: The role of particle technology in developing sustainable construction materials. Adv. Powder Technol. 21, 2–7 (2010)

Zhang, M.-H., Gjorv, O.: Microstructure of the interfacial zone between lightweight aggregate and cement paste. Cement Concrete Res. 20, 610–618 (1990)

Colangelo, F., Cioffi, R., Montagnaro, F., Santoro, L.: Soluble salt removal from MSWI fly ash and its stabilization for safer disposal and recovery as road basement material. Waste Manag. 32, 1179–1185 (2012)

Mehta, P., Monteiro, P.J.M.: Concrete: Microstructure, Properties, and Materials. McGraw-Hill Education, New York (2006)

Wasserman, R., Bentur, A.: Effect of lightweight fly ash aggregate microstructure on the strength of concretes. Cement Concrete Res. 27, 525–537 (1997)

de Gennaro, R., Cappelletti, P., Cerri, G., de’Gennaro, M., Dondi, M., Langella, A.: Neapolitan yellow tuff as raw material for lightweight aggregates in lightweight structural concrete production. Appl. Clay Sci. 28, 309–319 (2005)

Suomen Standardisoimisliitto SFS ry SFS-EN 12457-3: Characterisation of waste. Leaching. Compliance test for leaching of granular waste materials and sludges. Part 3: Two stage batch test at a liquid to solid ratio of 2 l/kg and 8 l/kg for materials with high solid content and with particle size below 4 mm (without or with size reduction) (2002)

Duxson, P., Provis, J.L., Lukey, G.C., Mallicoat, S.W., Kriven, W.M., van Deventer, J.S.J.: Understanding the relationship between geopolymer composition, microstructure and mechanical properties. Colloids Surf. Physicochem. Eng. Asp. 269, 47–58 (2005)

González-Corrochano, B., Alonso-Azcárate, J., Rodas, M.: Characterization of lightweight aggregates manufactured from washing aggregate sludge and fly ash. Resour. Conserv. Recycl. 53, 571–581 (2009)

Li, Y., Wu, D., Zhang, J., Chang, L., Wu, D., Fang, Z., Shi, Y.: Measurement and statistics of single pellet mechanical strength of differently shaped catalysts. Powder Technol. 113, 176–184 (2000)

British society of soil science ISO/CD 11273-3: Soil quality determination of aggregate stability. Part 2: Method by shear test (2000)

González-Corrochano, B., Alonso-Azcárate, J., Rodas, M.: Production of lightweight aggregates from mining and industrial wastes. J. Environ. Manage 90, 2801–2812 (2009)

Criado, M., Fernández-Jiménez, A., de la Torre, A.G., Aranda, M.A.G., Palomo, A.: An XRD study of theeffect of the SiO2/Na2O ratio on the alkali activation of fly ash. Cement Concrete Res. 37, 671–679 (2007)

Van Jaarsveld, J.G.S., Van Deventer, J.S.J.: Effect of the alkali metal activator on the properties of fly ash-based geopolymers. Ind. Eng. Chem. Res. 38, 3932–3941 (1999)

Williams, R.P., Van Riessen, A.: Determination of the reactive component of fly ashes for geopolymer production using XRF and XRD. Fuel 89, 3683–3692 (2010)

Guo, X., Shi, H., Dick, W.A.: Compressive strength and microstructural characteristics of class C fly ash geopolymer. Cement Concrete Compos. 32, 142–147 (2010)

Provis, J.L., Lukey, G.C., van Deventer, J.S.J.: Do geopolymers actually contain nanocrystalline zeolites? A reexamination of existing results. Chem. Mater. 17, 3075–3085 (2005)

García-Lodeiro, I., Palomo, A., Fernández-Jiménez, A., Macphee, D.E.: Compatibility studies between N–A–S–H and C–A–S–H gels. Study in the ternary diagram Na2O-CaO-Al2O3–SiO2–H2O. Cement Concrete Res. 41, 923–931 (2011)

Myers, R.J., Bernal, S.A., Provis, J.L.: A thermodynamic model for C–(N–)A–S–H gel: CNASH-ss. Derivation and validation. Cement Concrete Res. 66, 27–47 (2014)

Somna, K., Jaturapitakkul, C., Kajitvichyanukul, P., Chindaprasirt, P.: NaOH-activated ground fly ash geopolymer cured at ambient temperature. Fuel 90, 2118–2124 (2011)

Acknowledgments

This work was carried out under the auspices of the GEOPO Project, supported by the Finnish Funding Agency for Technology and Innovation (Tekes) and various companies (Boliden Harjavalta, Ekokem, Fortum, Helen Oy, Jyväskylän Energia, Kemira, Valmet Power, Metsä Group, Rovaniemen Energia, Stora Enso, and UPM). The authors would like to thank the Renlund Foundation for its financial support. Mr. Jarno Karvonen and Mr. Jani Österlund are acknowledged for their contributions to the laboratory analyses. The personnel of Center of Microscopy and Nanotechnology are acknowledged for their contributions to the FESEM- and XRD-analyses.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Yliniemi, J., Tiainen, M. & Illikainen, M. Microstructure and Physical Properties of Lightweight Aggregates Produced by Alkali Activation-High Shear Granulation of FBC Recovered Fuel-Biofuel Fly Ash. Waste Biomass Valor 7, 1235–1244 (2016). https://doi.org/10.1007/s12649-016-9509-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12649-016-9509-1