Abstract

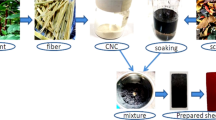

The disposal of huge quantities of leather wastes in open environment produces several toxic contaminants. An alternative to disposal of these wastes is to reuse them. In the present work, we have proposed a method to utilize collagen and chrome shaving wastes (CCS) to prepare composite sheets employing polyvinylpyrrolidone (PVP). The formed CCS/PVP composite sheets were characterized for their thermal, mechanical and morphological properties. It has been found that the mechanical properties of the composite sheets increase as the concentration of PVP increases from 2.5 to 10 wt%. Scanning electron microscopic studies reveal that the incorporation of PVP in the composite sheets resulted in increased interfacial adhesion thereby leading to reduced debonding between fibers. Fourier-transform infrared analysis of the composite sheets revealed the presence of dominant peaks associated with both collagen as well as PVP. It has also been demonstrated that the thermal stability of the formed composite sheets increases significantly as the concentration of PVP increases. These results demonstrate the homogeneity of the developed composite sheets. The obtained results suggest that the PVP incorporated composite sheets were found to have improved characteristics and hence suitable for numerous applications in footwear, clothing and related industries.

Similar content being viewed by others

References

Cassano, A., Drioli, E., Molinari, R.: Recovery and reuse of chemicals in unhairing, degreasing and chromium tanning processes by membranes. Desalination 113, 251–261 (1997)

Cassano, A., Drioli, E., Molinari, R.: Saving of water and chemicals in tanning industry by membrane processes. Water Res. 4, 443–450 (1999)

Aceves, M.B., Velasquez, R.O., Vazquez, R.R.: Effect of Cr3+, Cr6+ and tannery sludge on C and N mineralization and microbial activity in semi-arid solids. J. Hazard. Mater. 143, 522–531 (2007)

Stern, F.B., Beaumont, J.J., Halperin, W.E., Murthy, L.I., Hills, B.W., Fajen, J.M.: Mortality of chrome leather tannery workers and chemical exposures in tanneries. Scand. J. Work. Environ. Health 13, 108–117 (1987)

Heidemann, E.: Disposal and recycling of chrome-tanned materials. J. Am. Leather Chem. Assoc. 86, 331–333 (1991)

Cabeza, L.F., Mcaloon, A.J., Yee, W.C., Taylor, M.M., Brown, E.M., Marmer, W.N.: Process simulation and cost estimation of treatment of chromium-containing leather waste. J. Am. Leather Chem. Assoc. 93, 2990–3135 (1998)

Dayan, A.D., Paine, A.J.: Mechanisms of chromium toxicity, carcinogenicity and allergenicity: review of the literature from 1985 to 2000. Hum. Exp. Toxicol. 20, 439–451 (2001)

Costa, M.: Toxicity and carcinogenicity of Cr(VI) in animal models and humans. Crit. Rev. Toxicol. 27, 431–442 (1997)

Rajaram, J., Rajinikanth, B., Gnanamani, A.: Preparation, characterization and application of leather particulate-polymer composites. J. Polym. Environ. 17, 181–186 (2009)

Tahiri, S., Bouhria, M., Albizane, A., Messaoudi, A., Azzi, M., Alami, S.Y., Mabrour, J.: Extraction of proteins from chrome shavings with sodium hydroxide and reuse of chromium in the tanning process. J. Am. Leather Chem. Assoc. 99, 16–25 (2004)

Brown, M., Taylor, M.M., Marmer, W.N.: Production and potential uses of coproducts from solid tannery waste. J. Am. Leather Chem. Assoc. 91, 270–276 (1996)

Mu, C.D., Lin, W., Zhang, M.R., Zhu, Q.: Towards zero discharge of chromium containing leather waste trough improved alkali hydrolysis. Waste Manag. 23, 835–843 (2003)

Guardini, G.: Extraction of proteins and chromium sulphate from chromium tanned skin waste. U.S. Patent 4,483, 829 (1983)

Holloway, D.F.: Recovery and separation of nutritious proteins hydrolysates and chromium from chrome leather scrap. U.S. Patent 4,100,154 (1978)

Galatik, A., Duda, J., Minarik, L.: Pressure hydrolysis of leather waste with sodium hydroxide. Czech Patent CS 252, 382 (1988)

Tahiri, S., Azzi, M., Albizane, A., Messaoudi, A., Bouhria, M., Alami, Y.S., Mourid, A., Amrhar, J.: Study of quality of a pigment prepared by complexation of chromates recovered from treated chrome shavings and tanned splits. J. Am. Leather Chem. Assoc. 96, 426–436 (2001)

Berry, F.J., Constantini, N., Smart, L.E.: Synthesis of chromium-containing pigment from chromium recovered from leather waste. Waste Manag 22, 761–772 (2002)

Wojciech, L., Mieczyslzw, G., Urszula, M.: Leather treatment to remove chromium. PCT Int. Appl. WO 9803685 (1998)

Taylor, M.M., Diefendorf, E.J., Marmer, W.N., Brown, E.M.: Effect of various alkalinity-inducing agent on chemical and physical properties of protein isolated from chromium-containing leather waste. J. Am. Leather Chem. Assoc. 89(7), 221–228 (1994)

Cabeza, L.F., Taylor, M.M., DiMaio, G.L., Brown, E.M., Marmer, W.N., Carrio, R., Celma, P.J., Cot, J.: Processing of leather waste pilot scale studies on chrome shavings. Isolation of potentially valuable protein products and chromium. Waste Manag 18, 211–218 (1998)

Gammoun, A., Tahiri, S., Albizane, A., Azzi, M., Moros, J., Garrigues, S., Guardia, M.D.L.: Separation of motor oils, oily wastes and hydrocarbons from contaminated water by sorption on chrome shavings. J. Hazard. Mater. 145, 148–153 (2007)

Basegio, T., Haas, C., Pokorny, A., Bernardes, A.M., Bergmann, C.P.: Production of materials with alumina and ashes from incineration of chromium tanned leather shavings: environmental and technical aspects. J. Hazard. Mater. 137, 1156–1164 (2006)

Trezza, M.A., Scian, A.N.: Waste with chrome in the Portland cement clinker production. J. Hazard. Mater. 147, 188–196 (2007)

Przepiorkowska, A., Chronska, K., Zaborski, M.: Chrome-tanned leather shavings as a filler of butadiene-acrylonitrile rubber. J. Hazard. Mater. 141, 252–257 (2007)

Mathieu, A.N.: Improvement in the manufacture of leather paste board and paper. U.S. Patent 20,020 (1868)

Horowitz, A.R., Brooklyn, N.Y.: Method for the treatment and utilization of scrap or waste leather. U.S. Patent 2,148,904 (1939)

Case, A.W.: Manufactured leather. U.S. Patent 878,485 (1908)

Coulson, N.S., Kinsley, H.B., Nunn, J.K.: Composite leather material. U.S. Patent Appl. US2007/0184742A1 (2007)

Pelzer, H.: Moulded articles with leather-like surface properties for use in the automobile industry. U.S. Patent 5, 624, 619 (1997)

Henke, E.W.: Reconstitute leather and method of manufacturing same. U.S. Patent 4,497,871 (1985)

Przepiorkowska, A., Prochon, M., Zaborski, M.: Use of waste collagen as a filler for rubber compounds. J. Soc. Leather Technol. Chem. 88, 223–227 (2004)

Klasek, A., Simonikova, J., Pavelka, F.: Grafting of 2-hydroxyethyl methacrylate and methyl methacrylate onto chrome tanned collagen fibers. J. Appl. Polym. Sci. 31, 2007–2019 (1986)

Santana, T.J.M., Moreno, F.V.: Graft polymerization of methyl methacrylate onto short leather fibers. Polym. Bull. 42, 329–336 (1999)

Jordan, E.F., Feairheller, S.F.: Polymer–leather composites II. Kinetics of the deposition of selected acrylate monomers by polymerization into chrome-tanned cattle hide. J. Appl. Polym. Sci. 25, 2755–2776 (1980)

Santana, T.J.M., Torres, A.C., Lucero, A.M.: Extrusion and mechanical characterization of PVC-leather fiber composites. Polym. Compos. 19, 431–439 (1998)

Santana, T.J.M., Vega, M.J.A., Lucero, A.M., Moreno, F.V.: Production of leather-like composites using chemically modified short leather fibers. I: Chemical modification by emulsion polymerization. Polym. Compos. 23, 49–60 (2002)

Ramaraj, B.: Mechanical and thermal properties of ABS and leather waste composites. J. Appl. Polym. Sci. 101, 3062–3066 (2006)

Santana, T.J.M., Vega, M.J.A., Marquez, A., Moreno, F.V., Richardson, M.O.W., Machin, J.L.C.: Production of leather-like composites using short leather fibers. II. Mechanical characterization. Polym. Compos. 23, 991–1002 (2002)

Andreopoulos, A.G., Tarantili, P.A.: Waste leather particles as a filler for poly(vinyl chloride) plastisols. J. Maromol. Sci. Part A Pure Appl. Chem. 37, 1353–1362 (2000)

Babanas, K., Tarantili, P.A., Andreopoulos, A.G.: Plasticized poly (vinyl chloride) filled with waste leather particles. J. Elastomeres Plast. 33, 72–85 (2001)

Chronska, K., Przepiorkowska, A.: Buffing dust as a filler of carboxylated butadiene-acrylonitrile rubber and butadiene-acrylonitrile rubber. J. Hazard. Mater. 151, 348–355 (2008)

ASTM: International Annual Book of ASTM Standards, vol. 15.04. ASTM International, West Conshohocken, PA (2001)

IUP 36: Measurement of leather softness. J. Soc. Leather Technol. Chem. 84, 377–379 (2000)

IS 5914: Methods of Physical Testing of Leathers. Bureau of Indian Standards, New Delhi, India (1970)

Koo, C.M., Ham, H.T., Choi, M.H., Kim, S.O., Chung, I.J.: Characteristics of polyvinylpyrrolidone-layered silicate nanocomposites prepared by attrition ball milling. Polymer 44, 681–689 (2003)

Chang, M.C., Tanaka, J.: FT-IR study for hydroxyapatite/collagen nanocomposite cross-linked by glutraldehyde. Biomaterials 23, 4811–4818 (2002)

Acknowledgements

The authors gratefully thank the Council of Scientific and Industrial Research (CSIR), India for providing financial assistance under YSA project scheme. The authors also thank Mrs. G. Safi and Ms D.R. Jini for their valuable help and contributions in carrying out some of the experiments.

Author information

Authors and Affiliations

Corresponding authors

Rights and permissions

About this article

Cite this article

Ashokkumar, M., Thanikaivelan, P., Murali, R. et al. Preparation and Characterization of Composite Sheets from Collagenous and Chromium–Collagen Complex Wastes Using Polyvinylpyrrolidone: Two Problems, One Solution. Waste Biomass Valor 1, 347–355 (2010). https://doi.org/10.1007/s12649-010-9030-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12649-010-9030-x