Abstract

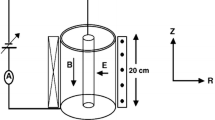

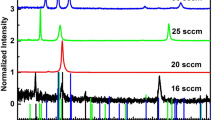

Copper oxide thin films were grown by DC reactive magnetron sputtering. The structural investigation of the sputtered films was carried out using X-ray diffraction. The surface morphology of the films was observed through atomic force microscopy. A crossover in the crystalline phase from cuprous to cupric oxide (tenorite) was observed as a result of variation in the oxygen flow rate during sputtering. Deposition rate was also found to be a function of the oxygen flow rate, and it was found that the deposition rate decreased with an increase in the oxygen flow rate which could be attributed to the possible target oxidation at higher oxygen flow rates. Variation of grain size of the films with oxygen flow rate was analyzed through AFM analysis. Dependence of oxygen flow rate on the formation of two phases of copper oxide was also confirmed through the optical band gap measurements.

Similar content being viewed by others

References

B Saha, R Thapa, S Jana, and K K Chattopadhyay Indian J. Phys. 84 1341 (2010)

B V Rajendra and D Kekuda Indian J. Phys. 88 585 (2014)

C W Ou et al. Appl. Phys. Lett. 92 122113 (2008)

K P Muthe et al. Thin Solid Films 324 37 (1998)

V Figueiredo et al. J. Display Tech. 9 735 (2013)

P Pattanasattayavong, S Thomas, G Adamopoulos, M A McLachlan, and T D Anthopoulos Appl. Phy. Lett. 102 163505 (2013)

S Kose, F Atay, V Bilgin, and I Akyuz Mater. Chem. Phys. 111 351 (2008)

A Chen, H Long, X Li, Y Li, G Yang, and P Lu Vacuum 83 927 (2009)

K Matsuzaki, K Nomura, H Yanagi, T Kamiya, M Hirano, and H Hosono Appl. Phys. Lett. 93 202107 (2008)

A Y Oral, E Menşur, M H Aslan, and E Başaran Mater. Chem. Phys. 83 140 (2004)

M F A Kuhaili Vacuum 82 623 (2008)

B Balamurugan and B R Mehta Thin Solid Films 396 90 (2001)

N Elfadill, M R Hashim, K Chahrour, M A Qaeed, and W Chunsheng J. Mater. Sci. Mater. Electron 25 262 (2014)

A A Ogwu, E Bouquerel, O Ademosu, S Moh, E Crossan, and F Placido J. Phys. D. Appl. Phys. 38 266 (2005)

P K Ooi, S S Ng, M J Abdullah, H A Hassan, and Z Hassan Mater. Chem. Phys. 140 243 (2013)

A R Rastkar, A R Niknam, and B Shokri Thin Solid Films 517 5464 (2009)

H Zhu, J Zhang, C Li, F Pan, T Wang, and B Huang Thin Solid Films 517 5700 (2009)

A S Reddy, P S Reddy, S Uthanna, G V Rao, and A Klein Phys. Status Solidi A 203 844 (2006)

A S Reddy et al. Mater. Chem. Phys. 110 397 (2008)

K C Sanal, L S Vikas, and M K Jayaraj Appl. Surf. Sci. 297 153 (2014)

H C Lu, C L Chu, C Y Lai, and Y H Wang Thin Solid Films 517 4408 (2009)

P V Plunkett, R M Johnson, and C D Wiseman Thin Solid Films 64 121 (1979)

M H P Reddy, J F Pierson, and S Uthanna Phys. Status Solidi A 209 1286 (2012)

Acknowledgments

Authors would like to thank Board of Research for Nuclear Sciences (BRNS) for funding the project (Sanction Letter No: 2012/20/34/4/BRNS/178 dated 19-04-2012). Authors would also like to thank Manipal University for all the necessary support during the project.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Ali, M., Gobinner, C.R. & Kekuda, D. Role of oxygen flow rate on the structural and optical properties of copper oxide thin films grown by reactive magnetron sputtering. Indian J Phys 90, 219–224 (2016). https://doi.org/10.1007/s12648-015-0745-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12648-015-0745-1