Abstract

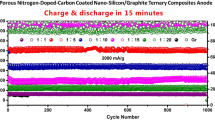

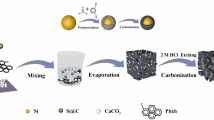

Porous silicon/carbon (Si/C) anode materials for Lithium-ion batteries was synthesized successfully by hydrochloric acid etching and calcination method using micron Si-Al alloy as silicon source and phenolic resin as carbon source. The microstructure and morphology were characterized by XRD, SEM, TEM, XPS and BET. The electrochemical performance were measured by constant current charge-discharge test and EIS. The results show that Si/C is porous structure and its pores are distributed between 1 and 6 nm. The specific discharge specific capacity of Si/C is 1287.0 mAh/g at a current density of 100 mA/g after 50 cycles, corresponding to the capacity retention of 91.0 % (for the second cycle). Si/C delivers a high specific discharge capacity of 605.9 and 359.0 mAh/g at 1 A/g and 2 A/g, respectively. The lithium ion diffusion coefficient of Si/C is 5.98 × 10− 11 cm2 s− 1, which is higher than that of 7.57 × 10− 12 cm2 s− 1 for porous Si.

Similar content being viewed by others

References

Guo R, Zhang S, Ying H, Yang W, Wang J, Han WQ (2019) New, effective, and low-cost dual-functional binder for porous silicon anodes in Lithium-Ion batteries. ACS Appl Mater Interfaces 11(15):14051–14058. https://doi.org/10.1021/acsami.8b21936

Zhang J, Chen Y, Chen X, Feng T, Yang P, An M (2020) Preparation of graphene-like carbon attached porous silicon anode by magnesiothermic and nickel-catalyzed reduction reactions. Ionics 26(12):5941–5950. https://doi.org/10.1007/s11581-020-03746-8

Zhang H, Xu H, Jin H, Li C, Bai Y, Lian K (2017) Flower-like carbon with embedded silicon nano particles as an anode material for Li-ion batteries. RSC Adv 7(48):30032–30037. https://doi.org/10.1039/c7ra03576d

Yin Y, Arca E, Wang L, Yang G, Schnabel M, Cao L, Xiao C, Zhou H, Liu P, Nanda J, Teeter G, Eichhorn B, Xu K, Burrell A, Ban C (2020) Nonpassivated silicon anode surface. ACS Appl Mater Interfaces 12(23):26593–26600. https://doi.org/10.1021/acsami.0c03799

Guan P, Li J, Lu T, Guan T, Ma Z, Peng Z, Zhu X, Zhang L (2018) Facile and scalable approach to fabricate granadilla-like porous-structured silicon-based anode for lithium ion batteries. ACS Appl Mater Interfaces 10(40):34283–34290. https://doi.org/10.1021/acsami.8b12071

Wang CM, Li X, Wang Z, Xu W, Liu J, Gao F, Kovarik L, Zhang JG, Howe J, Burton DJ, Liu Z, Xiao X, Thevuthasan S, Baer DR (2012) In situ TEM investigation of congruent phase transition and structural evolution of nanostructured silicon/carbon anode for lithium ion batteries. Nano Lett 12(3):1624–1632. https://doi.org/10.1021/nl204559u

Tesfaye AT, Gonzalez R, Coffer JL, Djenizian T (2015) Porous silicon nanotube arrays as anode material for li-ion batteries. ACS Appl Mater Interfaces 7(37):20495–20498. https://doi.org/10.1021/acsami.5b05705

Wang J, Wang C, Zhu Y, Wu N, Tian W (2014) Electrochemical stability of optimized Si/C composites anode for lithium-ion batteries. Ionics 21(2):579–585. https://doi.org/10.1007/s11581-014-1331-9

Ge M, Lu Y, Ercius P, Rong J, Fang X, Mecklenburg M, Zhou C (2014) Large-scale fabrication, 3D tomography, and lithium-ion battery application of porous silicon. Nano Lett 14(1):261–268. https://doi.org/10.1021/nl403923s

Guo S, Hu X, Hou Y, Wen Z (2017) Tunable synthesis of yolk-shell porous Silicon@Carbon for optimizing si/c-based anode of lithium-ion batteries. ACS Appl Mater Interfaces 9(48):42084–42092. https://doi.org/10.1021/acsami.7b13035

Li S, Qin X, Zhang H, Wu J, He Y-B, Li B, Kang F (2014) Silicon/carbon composite microspheres with hierarchical core–shell structure as anode for lithium ion batteries. Electrochem Commun 49:98–102. https://doi.org/10.1016/j.elecom.2014.10.013

Xi F, Zhang Z, Wan X, Li S, Ma W, Chen X, Chen R, Luo B, Wang L (2020) High-performance porous silicon/nanosilver anodes from industrial low-grade silicon for lithium-ion batteries. ACS Appl Mater Interfaces 12(43):49080–49089. https://doi.org/10.1021/acsami.0c14157

Liu X, Wang Z, Guo H, Li X, Zhou R, Zhou Y (2017) Chitosan: A N-doped carbon source of silicon-based anode material for lithium ion batteries. Ionics 23(9):2311–2318. https://doi.org/10.1007/s11581-017-2073-2

Shen K, Chen H, Hou X, Wang S, Qin H, Gao Y, Shen J (2020) Mechanistic insight into the role of N-doped carbon matrix in electrospun binder-free Si@C composite anode for lithium-ion batteries. Ionics 26(7):3297–3305. https://doi.org/10.1007/s11581-020-03484-x

Zhang H, Xu H, Lou X, Jin H, Zong P, Li S, Bai Y, Ma F (2019) Micro-structured Si@Cu3Si@C ternary composite anodes for high-performance Li-ion batteries. Ionics 25(10):4667–4673. https://doi.org/10.1007/s11581-019-03043-z

Zhang X, Zhou L, Huang M, Yang C, Xu Y, Huang J (2018) Synthesis of porous Si/C by pyrolyzing toluene as anode in lithium-ion batteries with excellent lithium storage performance. Ionics 25(5):2093–2102. https://doi.org/10.1007/s11581-018-2601-8

Zhou R, Fan R, Tian Z, Zhou Y, Guo H, Kou L, Zhang D (2016) Preparation and characterization of core–shell structure Si/C composite with multiple carbon phases as anode materials for lithium ion batteries. J Alloy Compd 658:91–97. https://doi.org/10.1016/j.jallcom.2015.10.217

Xu R, Zhang K, Wei R, Yuan M, Zhang Y, Liang F, Yao Y (2019) High-capacity flour-based nano-Si/C composite anode materials for lithium-ion batteries. Ionics 26(1):1–11. https://doi.org/10.1007/s11581-019-03224-w

Xu Q, Li J-Y, Sun J-K, Yin Y-X, Wan L-J, Guo Y-G (2017) Watermelon-inspired Si/C microspheres with hierarchical buffer structures for densely compacted lithium-ion battery anodes. Adv Energy Mater 7(3):1601481. https://doi.org/10.1002/aenm.201601481

Deng Y, Kang T, Ma Z, Tan X, Song X, Wang Z, Pang P, Shu D, Zuo X, Nan J (2019) Safety influences of the Al and Ti elements modified LiCoO2 materials on LiCoO2/graphite batteries under the abusive conditions. Electrochim Acta 295:703–709

Wang J, Zhang L, Zhang H (2018) Effects of electrolyte additive on the electrochemical performance of Si/C anode for lithium-ion batteries. Ionics 24(11):3691–3698. https://doi.org/10.1007/s11581-018-2682-4

Sun X, Li X, Wang J, Chen W (2019) MWCNT/Cellulose collector as scaffold of nano-silicon for Li-Si battery. Silicon 11:1955–1962. https://doi.org/10.1007/s12633-018-0013-z

Ge M, Rong J, Fang X, Zhou C (2012) Porous doped silicon nanowires for lithium ion battery anode with long cycle life. Nano Lett 12(5):2318–2323. https://doi.org/10.1021/nl300206e

Yan L, Yong W, Zou Y, Zheng J, Wu M (2010) Macroporous Co 3O 4 platelets with excellent rate capability as anodes for lithium ion batteries. Electrochem Commun 12(1):101–105

Tang J, Dysart AD, Kim DH, Saraswat R, Shaver GM, Pol VG (2017) Fabrication of carbon/silicon composite as lithium-ion anode with enhanced cycling stability. Electrochim Acta 247:626–633. https://doi.org/10.1016/j.electacta.2017.06.178

Su M, Wang Z, Guo H, Li X, Huang S, Gan L (2013) Silicon, flake graphite and phenolic resin-pyrolyzed carbon based Si/C composites as anode material for lithium-ion batteries. Adv Powder Technol 24(6):921–925. https://doi.org/10.1016/j.apt.2013.01.002

Luo J, Ma B, Peng J, Wu Z, Luo Z, Wang X (2019) Modified chestnut-like structure silicon carbon composite as anode material for lithium-ion batteries. ACS Sustain Chem Eng 7(12):10415–10424. https://doi.org/10.1021/acssuschemeng.9b00616

Liang J, Zhang Z, Yang W, Liu Y, Zhang X, Javid M, Jung Y, Dong X (2020) Three-dimensional porous carbon skeleton supporting Si nanosheets as anode for high-performance lithium ion batteries. Ionics 26(5):2233–2245. https://doi.org/10.1007/s11581-019-03409-3

Kwon HJ, Hwang JY, Shin HJ, Jeong MG, Chung KY, Sun YK, Jung HG (2020) Nano/microstructured silicon-carbon hybrid composite particles fabricated with corn starch biowaste as anode materials for li-ion batteries. Nano Lett 20(1):625–635. https://doi.org/10.1021/acs.nanolett.9b04395

Jaumann T, Herklotz M, Klose M, Pinkert K, Oswald S, Eckert J, Giebeler L (2014) Tailoring hollow silicon–carbon nanocomposites as high-performance anodes in secondary lithium-based batteries through economical chemistry. Chem Mater 27(1):37–43. https://doi.org/10.1021/cm502520y

Huang X, Cen D, Wei R, Fan H, Bao Z (2019) Synthesis of porous Si/C composite nanosheets from vermiculite with a hierarchical structure as a high-performance anode for lithium-ion battery. ACS Appl Mater Interfaces 11(30):26854–26862. https://doi.org/10.1021/acsami.9b06976

Liu W, Xu H, Qin H, Lv Y, Wang L (2019) Silicon nanoparticles preparation by induction plasma technology for li-ion batteri-es anode material. Silicon 12:2259–2269. https://doi.org/10.1007/s12633-019-00320-4

Wang H-g, Yuan C, Zhou R, Duan Q, Li Y (2017) Self-sacrifice template formation of nitrogen-doped porous carbon microtubes towards high performance anode materials in lithium ion batteries. Chem Eng J 316:1004–1010. https://doi.org/10.1016/j.cej.2017.02.059

Zhang SS, Xu K, Jow TR (2006) EIS study on the formation of solid electrolyte interface in Li-ion battery. Electrochim Acta 51(8–9):1636–1640. https://doi.org/10.1016/j.electacta.20-05.02.137

Shi Q, Wu X, Chen S, Wu X, Liu J, Long R (2020) Carbon-nitrogen quantum dots modification of Li4Ti5O12 anode material for lithium-ion batteries. Ionics 26(7):3325–3331. https://doi.org/10.1007/s11581-020-03516-6

Acknowledgements

This work was supported by the National Natural Science Foundation of China.

Funding

Xiangxi Ores Minerals and New Materials Development and Service Center, Jishou 416000, Hunan, China.

Author information

Authors and Affiliations

Contributions

Provision of paper data, research ideas and designers, article writer.

Corresponding author

Ethics declarations

This article does not contain any studies with human participants performed by any of the authors.

Consent to Participate

Consent.

Consent for Publication

Consent.

Conflict of Interest

Not applicable.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Liu, Jl., Wu, Xm., Chen, S. et al. Phenolic Resin-coated Porous Silicon/carbon Microspheres Anode Materials for Lithium-ion Batteries. Silicon 14, 4823–4830 (2022). https://doi.org/10.1007/s12633-021-01240-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12633-021-01240-y