Abstract

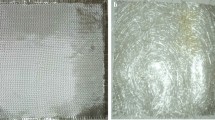

The present work aims to investigate the mechanical properties and fracture toughness of woven fabric Glass/Kevlar based hybrid composite tailored using modified epoxy with micro rubber and nano silica. The principal aim of this work is to clarify the importance of hybrid fibre/filler addition and stacking sequence of fibre reinforcement in epoxy matrix. The epoxy was modified with addition of 9% micro rubber and 11% of nano silica by weight fraction. Both glass and kevlar woven mats were made by hand weaving and the composites were prepared using hand lay-up method. The fracture toughness results revealed that the exclusive addition of rubber particles in epoxy reduces the strength and modulus but improved fracture toughness. Further tailoring the hybrid composite by adding nano silica of 11 wt.% increased tensile and flexural modulus. The highest tensile and flexural strength of 275 and 162 MPa was observed for composite, which contain nano silica as reinforcement at accumulate layer stacking sequence. The fractograph results revealed the dispersion of nano additions and fracture characteristics of hybrid composites. These mechanically toughened epoxy composites could be used in high damping mechanical applications.

Similar content being viewed by others

References

Arun Prakash VR, Rajadurai A (2016) Thermo-mechanical characterization of siliconized E-glass fibre/hematite particles reinforced epoxy resin hybrid composite. Applied Surfcae Science 384(16):99–106

Guru Raja M. N & A.N. Hari Rao, 2013, “Effect of an Angle-Ply Orientation on Tensile Properties of Kevlar/glass Hybrid Composites”, Volume-2, Issue-3, 891–899

Manjunath CM (2010) The tensile fatigue behavior of a glass fiber reinforced plastic composite using a hybrid toughened epoxy matrix. J Compos Mater 156(4):60–67

Park S-J, Seo M-K, Ma T-J, Lee D-R (2002) Effect of chemical treatment of Kevlar® fibers on mechanical interfacial properties of composites. J Colloid Interface Sci 252:249–255

Valenca SL, Griza S, De Oliveira VG, Sussuchi EM, De Cunha FGC (2015) Evaluation of the mechanical behavior of epoxy composite reinforced with Kevlar® plain fabric and glass/Kevlar® hybrid fabric. Compos Part B 70:1–8

Liang, Pearson RA (2010) The toughening mechanism in hybrid epoxy-silica- rubber nanocomposites (HESRNs). Polymer (Guildf) 51(21):4880–4890

Prakash VRA, Jaisingh SJ (2018) Mechanical strength behaviour of Silane treated E-glass fibre/Al 6061 & SS-304 wire mesh reinforced epoxy resin hybrid composite. Silicon 10:2279–2286

Dinesh T, Kadirvel A, Arunprakash (2018) Effect of Silane modified E-glass fibre/iron(III)oxide reinforcements on UP blended epoxy resin hybrid composite, silicon 10(3):1–12

Ramesh C, Manickam C, Maridurai T, Arun Prakash VR (2017) Dry sliding wear characteristics of heat treated and surface modified hematite particles-epoxy particulate composite. Romanian journal of materials 47(3):401–405

Arunprakash VR, Rajadurai A (2016) Mechanical, thermal and dielectric characterization of iron(III)oxide reinforced epoxy hybrid composite. Digest Journal of Nanomaterials and Biostructures 11:373–380

Peng CB, Akil HM, Affendy MG, Khan A, Nasir RBM (2014) Comparative study of wear performance of particulate and fiberreinforced nano-ZnO/ultra-high molecular weight polyethylene hybrid composites using response surface methodology. Material Design 63:805–819

Pontefisso A, Zappalorto M, Quaresimin M (2013) Influence of interphase and filler distribution on the elastic properties of nanoparticle filled polymers. Mech Res Commun 52:92–94

Hua Y, Gu L, Premaraj S, Zhang X (2015) Role of interface in the mechanical behaviour of silica/epoxy resin nanocomposites. Materials 8(6):3519–3531. https://doi.org/10.3390/ma8063519

Tsai JL, Huang BH, Cheng YL (2011) Enhancing fracture toughness of glass/epoxy composites for wind blades using silica nanoparticles and rubber particles. Procedia Engineering 14:1982–1987

Sobrinho LL, Calado VMA, Bastian FL (2011) Effects of rubber addition to an epoxy resin and its Fiber glass-reinforced composite. Polym Compos 33(2):295–305. https://doi.org/10.1002/pc.21265

Sokolova OA, Kuhn M, Palkowski H (2012) Deep drawing properties of light weight steel/polymer/steel sandwich composites. Archives of Civil and Mechanical Engineering 12:105–112

Silva H, Ferreira JA, Costa JD, Capela C (2013) A study of mixed mode inter-laminar fracture on nano clay enhanced epoxy/glass fiber composites. Ciencia & Tecnologia dos Materiais 25:92–97

Rathnakar G, Shivanand H (2013) Fibre orientation and its influence on the flexural strength of glass fibre and Graphite fibre reinforced polymer composites. International Journal of Innovative Research in Science Engineering and Technology 2(3):548–552Xxx

Arun Prakash VR, Rajadurai A (2017) Inter laminar shear strength behavior of acid, base and silane treated E-glass fibre epoxy resin composites on drilling process. Defence Technology 13:40–46

Selver E, Potluri P, Hogg P, Soutis C (2016) Impact damage tolerance of thermoset composites reinforced with hybrid commingled yarns. Compos Part B Eng 91(15):522–538

Domun N, Hadavinia H, Zhang T, Sainsbury T, Liaghat GH, Vahid S (2015) Improving the fracture toughness and the strength of epoxy using nanomaterials – a review of the current status. Nanoscale 7:10294–10329

Sathish KG, Siddeswarappa B, Kaleemulla KM (2010) Characterisation of in-plane mechanical properties of laminated hybrid composites. Journal of Minerals and Materials Characterization Engineering 9(2):105–114

Manikandan V, Jappes JTW, Kumar SMS, Amuthakkannan P (2012) Investigation of the effect of surface modifications on the mechanical properties of basalt fibre reinforced polymer composites. Compos Part B 43:812–818

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of Interest

The authors have no conflict of interest.

Rights and permissions

About this article

Cite this article

Gokuldass, R., Ramesh, R. Mechanical Strength Behavior of Hybrid Composites Tailored by Glass/Kevlar Fibre-Reinforced in Nano-Silica and Micro-Rubber Blended Epoxy. Silicon 11, 2731–2739 (2019). https://doi.org/10.1007/s12633-018-0064-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12633-018-0064-1