Abstract

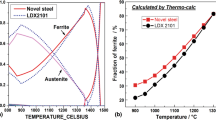

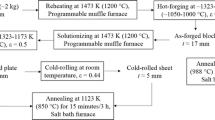

In this work, the microstructure and the strain partitioning of lean duplex stainless steel 2101 (LDX 2101) during different hot-rolling processes are investigated by optical microscopy and electron-backscattered diffraction (EBSD). The results show that the LDX 2101 exhibits poor thermoplasticity at high temperature. The four-pass hot-rolled plates show fewer edge-cracking defects and superior thermoplasticity compared with the two-pass hot-rolled plates prepared at different temperature. The phase boundary is the weakest site in the LDX 2101. The cracks are initiated and propagated along the phase boundaries during the hot-rolling process. According to the EBSD analysis, the increase of the hot-rolling pass can dramatically improve the strain distribution in ferrite and austenite phases and promote the strain transmission in the constituent phases, thereby improving the coordinated deformation ability of the two phases. This effect further increases the thermoplasticity and reduces the formation of edge cracks in LDX 2101.

Similar content being viewed by others

References

S.S. Sohn, K. Choi, J.H. Kwak, N.J. Kim, and S. Lee, Novel ferrite-austenite duplex lightweight steel with 77% ductility by transformation induced plasticity and twinning induced plasticity mechanisms, Acta Mater., 78(2014), p. 181.

N. Jia, R.L. Peng, G.C. Chai, S. Johansson, and Y.D. Wang, Direct experimental mapping of microscale deformation heterogeneity in duplex stainless steel, Mater. Sci. Eng. A, 491(2008), No. 1–2, p. 425.

Z.J. Gao, J.Y. Li, and Y.D. Wang, The crystallographic textures and anisotropy in 2507 super duplex stainless steel, Steel Res. Int., 90(2019), No. 2, art. No. 1800397.

Y. Zhao, W.N. Zhang, Z.Y. Liu, and G.D. Wang, Development of an easy-deformable Cr21 lean duplex stainless steel and the effect of heat treatment on its deformation mechanism, Mater. Sci. Eng. A, 702(2017), p. 279.

S.F. Yang, Y. Wen, P. Yi, K. Xiao, and C.F. Dong, Effects of chitosan inhibitor on the electrochemical corrosion behavior of 2205 duplex stainless steel, Int. J. Miner. Metall. Mater., 24(2017), No. 11, p. 1260.

Y.S. Sato, T.W. Nelson, C.J. Sterling, R.J. Steel, and C.O. Pettersson, Microstructure and mechanical properties of friction stir welded SAF 2507 super duplex stainless steel, Mater. Sci. Eng. A, 397(2005), No. 1–2, p. 376.

I.N. Bastos, S.S. Tavares, F. Dalard, and R.P. Nogueira, Effect of microstructure on corrosion behavior of superduplex stainless steel at critical environment conditions, Scr. Mater., 57(2007), No. 10, p. 913.

H. Miyamoto, T. Mimaki, and S. Hashimoto, Superplastic deformation of micro-specimens of duplex stainless steel, Mater. Sci. Eng. A, 319-321(2001), p. 779.

K.H. Lo, C.H. Shek, and J.K.L. Lai, Recent developments in stainless steels, Mater. Sci. Eng. R, 65(2009), No. 4–6, p. 39.

N. Zhou, R.L. Peng, and R. Pettersson, Surface integrity of 2304 duplex stainless steel after different grinding operations, J. Mater. Process. Technol., 229(2016), p. 294.

P. Cizek and B.P. Wynne, A mechanism of ferrite softening in a duplex stainless steel deformed in hot torsion, Mater. Sci. Eng. A, 230(1997), No. 1–2, p. 88.

W. Zhang, L.Z. Jiang, J.C. Hu, and S.H.M. Song, Effect of ageing on precipitation and impact energy of 2101 economical duplex stainless steel, Mater. Charact, 60(2009), No. 1, p. 50.

H.J. Aval, Mcrostructural evolution and mechanical properties of friction stir-welded C71000 copper-nickel alloy and 304 austenitic stainless steel, Int. J. Miner. Metall. Mater, 25(2018), No. 11, p. 1294.

Y.H. Yang and B. Yan, The microstructure and flow behavior of 2205 duplex stainless steels during high temperature compression deformation, Mater. Sci. Eng. A, 579(2013), p. 194.

Y.Y. Liu, H.T. Yan, X.H. Wang, and M. Yan, Effect of hot deformation mode on the microstructure evolution of lean duplex stainless steel 2101, Mater. Sci. Eng. A, 575(2013), p. 41.

C. Castan, F. Montheillet, and A. Perlade, Dynamic recrystal-lization mechanisms of an Fe-8% Al low density steel under hot rolling conditions, Scr. Mater, 68(2013), No. 60, p. 360.

X.F. Wang, W.Q. Chen, and H.G. Zheng, Influence of isothermal aging on o precipitation in super duplex stainless steel, Int. J. Miner. Metall. Mater, 17(2010), No. 4, p. 435.

Y.L. Chen, T.R. Zhang, Y.D. Wang, and J.Y. Li, Effects of O, N and Ni contents on hot plasticity of 0Cr25Ni7Mo4N duplex stainless steel Acta Metall. Sinica, 50(2014), No. 8, p. 905.

L. Chen, X.C. Ma, X. Liu, and L.M. Wang, Processing map for hot working characteristics of a wrought 2205 duplex stainless steel, Mater. Des., 32(2011), No. 3, p. 1292.

A. Momeni and K. Dehghani, Hot working behavior of 2205 austenite-ferrite duplex stainless steel characterized by constitutive equations and processing maps, Mater. Sci. Eng. A, 528(2011), No. 3, p. 1448.

L. Duprez, B.C. De Cooman, and N. Akdut, Flow stress and ductility of duplex stainless steel during high-temperature torsion deformation, Metall. Mater. Trans. A, 33(2002), No. 7, p. 1931.

M. Ma, H. Ding, Z.Y. Tang, J.W. Zhao, Z.H. Jiang, and G.W. Fan, Effects of temperature and strain rate on flow behavior and microstructural evolution of super duplex stainless steel under hot deformation, J. Iron Steel Res. Int., 23(2016), No. 3, p. 244.

J.A. Jiménez, F. Carreño, O.A. Ruano, and M. Carsí, High temperature mechanical behaviour of δ-γ stainless steel, Mater. Sci. Technol, 15(1999), No. 2, p. 127.

A. Iza-Mendia, A. Pinñol-Juez, J.J. Urcola, and I. Gutieérrez, Microstructural and mechanical behavior of a duplex stainless steel under hot working conditions, Metall. Mater. Trans. A, 29(1998), No. 12, p. 2975.

Z.H. Feng, J.Y. Li, and Y.D. Wang, The microstructure evolution of lean duplex stainless steel 2101, Steel Res. Int., 88(2017), No. 12, art. No. 1700177.

Acknowledgements

This research is financially supported by the National Natural Science Foundation of China (Nos. U1806220 and U1660114).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Gao, Zj., Li, Jy., Feng, Zh. et al. Influence of hot rolling on the microstructure of lean duplex stainless steel 2101. Int J Miner Metall Mater 26, 1266–1273 (2019). https://doi.org/10.1007/s12613-019-1841-6

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12613-019-1841-6