Abstract

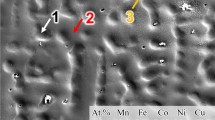

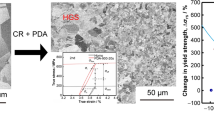

High-entropy alloys with high strength and acceptable ductility at both room and elevated temperatures for high-temperature structural applications are desired. In this paper, CrMnFeCoNi alloy with outstanding ductility but low strength was selected as baseline alloy to study the formation of hard phase to strengthen this ductile alloy by adding Al into it. The results indicate that there is a phase structure transition from fcc to bcc when adding enough Al into CrMnFeCoNi. The yield strength and hardness increase with the content of Al increasing, due to the formation of hard bcc phase in the ductile CrMnFeCoNi alloy. The CrMnFeCoNiAl alloy with a bcc structure shows a high yield strength and adequate ductility at elevated temperatures. At 400 and 500 °C, the yield strength and ductility of CrMnFeCoNiAl alloy are 975.59 MPa and 6.39% and 989.48 MPa and 9.15%, respectively. An example of tailoring the strength and ductility of high-entropy alloy is demonstrated in this paper.

Similar content being viewed by others

References

Cantor B, Chang ITH, Knight P, Vincent AJB. Microstructural development in equiatomic multicomponent alloys. Mater Sci Eng A. 2004;375–377(1):213.

Lu ZP, Wang H, Chen MW, Baker I, Yeh JW, Liu CT, Nieh TG. An assessment on the future development of high-entropy alloys: summary from a recent workshop. Intermetallics. 2015;66:67.

Tsai MH, Yeh JW. High-entropy alloys: a critical review. Mater Res Lett. 2014;2(3):107.

Miracle DB, Senkov ON. A critical review of high entropy alloys and related concepts. Acta Mater. 2017;122:448.

Ye QF, Feng K, Li ZG, Lu FG, Li RF, Huang J, Wu YX. Microstructure and corrosion properties of CrMnFeCoNi high entropy alloy coating. Appl Sur Sci. 2016;396:1420.

Chen J, Niu PY, Liu YZ, Lu YK, Wang XH, Peng YL, Liu JN. Effect of Zr content on microstructure and mechanical properties of AlCoCrFeNi high entropy alloy. Mater Des. 2016;94:39.

Tariq NH, Naeem M, Hasan BA, Akhter JI, Siddique M. Effect of W and Zr on structural, thermal and magnetic properties of AlCoCrCuFeNi high entropy alloy. J Alloys Compd. 2013;556:79.

Samal S, Mohanty S, Mishra AK, Biswas K, Govind B. Mechanical behavior of novel suction cast TiCuFeCoNi high entropy alloys. Mater Sci Forum. 2014;790:503.

Tazuddin, Biswas K, Gurao NP. Deciphering micro-mechanisms of plastic deformation in a novel single phase fcc-based MnFeCoNiCu high entropy alloy using crystallographic texture. Mater Sci Eng A. 2016;657:224.

Liu WH, Lu ZP, He JY, Luan JH, Wang ZJ, Liu B, Liu Y, Chen MW, Liu CT. Ductile CoCrFeNiMox high entropy alloys strengthened by hard intermetallic phases. Acta Mater. 2016;116:332.

Otto F, Yang Y, Bei H, George EP. Relative effects of enthalpy and entropy on the phase stability of equiatomic high-entropy alloys. Acta Mater. 2013;61(7):2628.

Chen MR, Lin SJ, Yeh JW, Chuang MH, Chen SK, Huang YS. Effect of vanadium addition on the microstructure, hardness, and wear resistance of Al0.5CoCrCuFeNi high-entropy alloy. Mater Trans A. 2006;37(5):1363.

Salishchev GA, Tikhonovsky MA, Shaysultanov DG, Stepanov ND, Kuznetsov AV, Kolodiy IV, Tortika AS, Senkov ON. Effect of Mn and V on structure and mechanical properties of high-entropy alloys based on CoCrFeNi system. J Alloys Compd. 2014;591(5):11.

Wang ZJ, Qiu WF, Yang Y, Liu CT. Atomic-size and lattice-distortion effects in newly developed high-entropy alloys with multiple principal elements. Intermetallics. 2015;64:63.

Wang ZJ, Huang YH, Yang Y, Wang JC, Liu CT. Atomic-size effect and solid solubility of multicomponent alloys. Scripta Mater. 2015;94:28.

Lin CM, Juan CC, Chang CH, Tsai CW, Yeh JW. Effect of Al addition on mechanical properties and microstructure of refractory AlxHfNbTaTiZr alloys. J Alloys Compd. 2015;624(5):100.

Li C, Xue YF, Hua MT, Cao TQ, Ma LL, Wang L. Microstructure and mechanical properties of AlxSi0.2CrFeCoNiCu1−x high-entropy alloys. Mater Des. 2016;90:601.

Tang WY, Yeh JW. Effect of aluminum content on plasma-nitrided AlxCoCrCuFeNi high-entropy alloys. Metall Mater Trans A. 2009;40(6):1479.

Hsu CY, Juan CC, Chen TS, Chen SK, Yeh JW. Effect of aluminum content on microstructure and mechanical properties of AlxCoCrFeMo0.5Ni high-entropy alloys. JOM. 2013;65(12):1840.

Yang TF, Xia SQ, Liu S, Wang CX, Liu SS, Zhang Y, Xue JM, Yan S, Wang YG. Effects of Al addition on microstructure and mechanical properties of AlxCoCrFeNi high-entropy alloy. Mater Sci Eng A. 2015;648:15.

Yeh JW, Chen SK, Lin SJ, Gan JY, Chin TS, Shun TT, Tsau CH, Chang SY. Nanostructured high-entropy alloys with multiple principal elements: novel alloy design concepts and outcomes. Adv Eng Mater. 2004;6(5):299.

Choudhuri D, Gwalani B, Gorsse S, Mikler CV, Ramanujan RV, Gibson MA, Banerjee R. Change in primary solidification phase from fcc to bcc-based B2 in high entropy alloy or complex concentrated alloys. Scripta Mater. 2017;127:186.

Chou HP, Chang YS, Chen SK, Yeh JW. Microstructure, thermophysical and electrical properties in AlxCoCrFeNi (0 ≤ x≤ 2) high-entropy alloys. Mater Sci Eng B. 2009;163(3):184.

Wang WR, Wang WL, Wang SC, Tsai YC, Lai CH, Yeh JW. Effects of Al addition on the microstructure and mechanical property of AlxCoCrFeNi high-entropy alloys. Intermetallics. 2012;26:44.

Wu PH, Liu N, Yang W, Zhu ZX, Lu YP, Wang XJ. Microstructure and solidification behavior of multicomponent CoCrCuxFeMoNi high-entropy alloys. Mater Sci Eng A. 2015;642:142.

Takeuchi A, Inoue A. Classification of bulk metallic glasses by atomic size difference, heat of mixing and period of constituent element and its application to characterization of the main alloying element. Mater Trans. 2005;46(12):2817.

Yang X, Zhang Y. Prediction of high-entropy stabilized solid-solution in multi-component alloys. Mater Chem Phys. 2012;132(2–3):233.

Zhang Y, Zhou YJ, Lin JP, Chen GL, Liaw PK. Solid solution phase formation rules for multicomponent alloys. Adv Eng Mater. 2008;10(6):534.

Niu SZ, Kou HC, Wang J, Li JS. Improved tensile properties of Al0.5CoCrFeNi high-entropy alloy by tailoring microstructures. Rare Met. 2017. https://doi.org/10.1007/s12598-016-0860-y.

He JY, Liu WH, Wang H, Wu Y, Liu XJ, Nieh TG, Lu ZP. Effect of Al addition on structural evolution and tensile properties of the FeCoNiCrMn high-entropy alloy system. Acta Mater. 2014;62(1):105.

Tong CJ, Chen YL, Chen SK, Yeh JW, Shun TT, Tsau CH. Microstructure characterization of AlxCoCrCuFeNi high-entropy alloy system with multiprincipal elements. Metall Mater Trans A. 2005;36(4):881.

Li C, Li JC, Zhao M, Jiang Q. Effect of aluminum contents on microstructure and properties of AlxCoCrFeNi alloys. J Alloys Compd. 2010;504(4):s515.

Acknowledgements

This work was financially supported by the National Magnetic Confinement Fusion Program of China (No. 2015GB121003), the National Natural Science Foundation of China (No. 51401071) and the Fundamental Research Funds for the Central Universities (No. PA2018GDQT0018).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Xian, X., Zhong, ZH., Lin, LJ. et al. Tailoring strength and ductility of high-entropy CrMnFeCoNi alloy by adding Al. Rare Met. 41, 1015–1021 (2022). https://doi.org/10.1007/s12598-018-1161-4

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12598-018-1161-4