Abstract

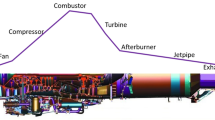

Based on the experience of the author, an overview of manufacturing technologies for TiAl alloy components in current and future applications is provided. The main current application consists of turbochargers for gasoline engines used in passenger vehicles, while future applications include high temperature turbochargers for passenger vehicle direct injection gasoline engines, mass production turbochargers for passenger vehicle diesel engines, and aerospace structural parts. The paper presented here first reviews the characteristics of the respective products together with the features of the TiAl alloys used or likely to be used. Representative manufacturing technologies are then presented with respect to these products, and desirable new technologies aimed toward future applications are discussed.

Similar content being viewed by others

References

Tetsui T., and Ono S., Endurance and composition and microstructure effects on endurance of TiAl used in turbocharger, Intermetallics, 1999, 17: 689.

Tetsui T., Application of TiAl in a turbocharger for passenger vehicles, Adv. Eng. Mat., 2001, 3: 307.

Tetsui T., Development of a TiAl turbocharger for passenger vehicles, Mat. Sci. Eng., 2002, A329–331: 582.

Fujimura T., Nishikawa H., Moriya N., and Imamura M., Development of GEnx turbofan engine, IHI Gihou (in Japanese), 2008–9, 48: 153.

Weimer M., and Kelly T., Gamma TiAl applications at GE Aviation, in Structural Aluminides for Elevated Temperatures. Gamma Titanium and Other Metallic Aluminides., 2008. 5

Noda T., Application of cast gamma TiAl for automobiles, Intermetallics, 1998, 16: 709.

Tetsui T., Development of a second generation TiAl turbocharger, Mater. Sci. Forum, 2007, 361–363: 379.

Noda T., Shimizu T., Okabe M., and Iikubo T., Joining of TiAl and steels by induction brazing, Mat. Sci. Eng., 1997, A239–240: 613.

Tetsui T., Kobayashi T., Mori T., Kishimoto T., and Harada H., Evaluation of yttria applicability as a crucible for induction melting of TiAl alloy, Mater. Trans., 2010, 51: 1656.

Tetsui T., Shindo K., Kobayashi S., and Takeyama M., A newly developed hot worked TiAl alloy for blades and structural components, Scripta Materialia, 2002, 47: 399.

Tetsui T., Shindo K., Kaji S., Kobayashi S., and Takeyama M., Fabrication of TiAl component by means of hot forging and machining, Intermetallics, 2005, 13: 971.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Tetsui, T. Manufacturing technology for gamma-TiAl alloy in current and future applications. Rare Metals 30 (Suppl 1), 294–299 (2011). https://doi.org/10.1007/s12598-011-0288-3

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12598-011-0288-3