Abstract

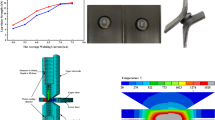

The use of high strength steels in car bodies has increased gradually in recent years, contributing to lighter weight vehicles. In general, the resistance spot weldability of high strength steels is poor when compared to that of low-carbon steels due to a number of factors including narrow welding range (weld lobe), irregular occurrence of expulsion, high resistivity of base metals, and zinc coating. To improve the weldability of high strength steels, technologies such as adaptive resistance spot welding and optimization of welding conditions have been developed and applied within the automotive industry. This study focuses on developing two methods of resistance spot welding with the aim of improving the weldability of high strength steels. The first method is reference welding, which uses the reference power waveforms obtained from preliminary welding. The second is modified reference welding, which uses modified power waveform from the reference welding method. The features and effects of these welding methods were evaluated through a tensile shear test, analysis of welding signals, and an investigation into the frequency of expulsion. Both welding methods showed high tensile shear strength results and reductions in expulsion over a wide variety of different steel types including GI coated steels.

Similar content being viewed by others

References

Oikawa, H., Murayama, G., Hiwatashi, S., and Matsuyama, K., “Resistance Spot Weldability of High Strength Steel Sheets for Automobiles and the Quality Assurance of Joints,” Welding in the World, Vol. 51, No. 3-4, pp. 7–18, 2007.

Miles, M., Hong, S.-T., Woodward, C., and Jeong, Y.-H., “Spot Welding of Aluminum and Cast Iron by Friction Bit Joining,” Int. J. Precis. Eng. Manuf., Vol. 14, No. 6, pp. 1003–1006, 2013.

Yang, H., Lai, X., Zhang, Y., and Chen, G., “Investigations on the Weldability of High-Strength Steels Sheet to Cylindrical Tube Single-Sided Spot Welding,” The International Journal of Advanced Manufacturing Technology, Vol. 49, No. 5-8, pp. 513–518, 2010.

Hayat, F. and Sevim, I., “The Effect of Welding Parameters on Fracture Toughness of Resistance Spot-Welded Galvanized DP600 Automotive Steel Sheets,” The International Journal of Advanced Manufacturing Technology, Vol. 58, No. 9-12, pp. 1043–1050, 2012.

Nonaka, T., Goto, K., Taniguchi, H., and Yamazaki, K., “Developments of Ultra High-Strength Cold-Rolled Steel Sheets for Automotive Use,” Nippon Steel Technical Report, No. 88, pp. 13–15, 2003.

Demeri, M. Y., “Advanced High-Strength Steels: Science, Technology, and Applications,” ASM International, pp. 194–196, 2013.

Donders, S., Brughmans, M., Hermans, L., and Tzannetakis, N., “The Effect of Spot Weld Failure on Dynamic Vehicle Performance,” Sound and Vibration, Vol. 39, No. 4, pp. 16–25, 2005.

Pouranvari, M. and Ranjbarnoodeh, E., “Effect of Welding Current on Energy Absorption of AISI 304 Resistance Spot Welds,” Research Journal of Applied Sciences, Engineering and Technology, Vol. 4, No. 17, pp. 2911–2914, 2012.

Pouranvari, M., Asgari, H. R., Mosavizadch, S. M., Marashi, P. H., and Goodarzi, M., “Effect of Weld Nugget Size on Overload Failure Mode of Resistance Spot Welds,” Science and Technology of Welding & Joining, Vol. 12, No. 3, pp. 217–225, 2007.

Tumuluru, M. D., “Resistance Spot Welding of Coated High-Strength Dual-Phase Steels,” Welding Journal, Vol. 85, No. 8, pp. 31–37, 2006.

Khan, M., Kuntz, M., Biro, E., and Zhou, Y., “Microstructure and Mechanical Properties of Resistance Spot Welded Advanced High Strength Steels,” Materials Transactions, Vol. 49, No. 7, pp. 1629–1637, 2008.

Marya, M. and Gayden, X., “Development of Requirements for Resistance Spot Welding Dual-Phase (DP600) Steels Part 1 -The Causes of Interfacial Fracture,” Welding Journal, Vol. 84, No. 11, pp. 172–182, 2005.

Brown, B. M., “A Comparison of AC and DC Resistance-Welding of Automotive Steels,” Welding Journal, Vol. 66, No. 1, pp. 18–23, 1987.

Li, W., Cerjanec, D., and Grzadzinski, G. A., “A Comparative Study of Single-Phase AC and Multiphase DC Resistance Spot Welding,” Journal of Manufacturing Science and Engineering, Vol. 127, No. 3, pp. 583–589, 2005.

Alfaro, S. C. A., Vargas, J. E., Wolff, M. A., and Vilarinho, L. O., “Comparison between AC and MF-DC Resistance Spot Welding by using High Speed Filming,” Journal of Achievements in Materials and Manufacturing Engineering, Vol. 24, No. 1, pp. 333–339, 2007.

Dennison, A. V., Toncich, D. J., and Masood, S., “Control and Process-based Optimisation of Spot-Welding in Manufacturing Systems,” The International Journal of Advanced Manufacturing Technology, Vol. 13, No. 4, pp. 256–263, 1997.

Thakur, A. G. and Nandedkar, V. M., “Optimization of the Resistance Spot Welding Process of Galvanized Steel Sheet using the Taguchi Method,” Arabian Journal for Science and Engineering, Vol. 39, No. 2, pp. 1171–1176, 2014.

Iyota, M., Mikami, Y., Hashimoto, T., Taniguchi, K., Ikeda, R., and Mochizuki, M., “Effect of Electrode Force Condition on Nugget Diameter and Residual Stress in Resistance Spot Welded High-Strength Steel Sheets,” Journal of Physics: Conference Series, Vol. 379, No. 1, Paper No. 012051, 2012.

Sun, H. T., Lai, X. M., Zhang, Y. S., and Shen, J., “Effect of Variable Electrode Force on Weld Quality in Resistance Spot Welding,” Science and Technology of Welding and Joining, Vol. 12, No. 8, pp. 718–724, 2007.

Matsushita, M., Taniguchi, K., and Oi, K., “Development of Next Generation Resistance Spot Welding Technologies Contributing to Auto Body Weight Reduction,” JFE Technical Report, No. 18, pp. 111–117, 2013.

Zhou, K. and Cai, L., “Online Nugget Diameter Control System for Resistance Spot Welding,” The International Journal of Advanced Manufacturing Technology, Vol. 68, No. 9-12, pp. 2571–2588, 2013.

Yu, J., “Quality Estimation of Resistance Spot Weld based on Logistic Regression Analysis of Welding Power Signal,” Int. J. Precis. Eng. Manuf., Vol. 16, No. 13, pp. 2655–2663, 2015.

Yu, J., Choi, D., and Rhee, S., “Improvement of Weldability of 1 GPa Grade Twin-Induced Plasticity Steel,” Welding Journal, Vol. 93, No. 3, pp. 78s–84s, 2014.

Mizumoto, M., “Product-Sum-Gravity Method -Fuzzy Singleton-Type Reasoning Method -Simplified Fuzzy Reasoning Method,” Proc. of 5th IEEE International Conference on Fuzzy Systems, Vol. 3, pp. 2098–2102, 1996.

Yu, J.-Y., Yun, S.-M., and Rhee, S.-H., “Optimization of Fuzzy Controller for Constant Current of Inverter DC Resistance Spot Welding using Genetic Algorithm,” Journal of Welding and Joining, Vol. 28, No. 5, pp. 99–105, 2010.

Cho, Y. and Rhee, S., “Primary Circuit Dynamic Resistance Monitoring and Its Application to Quality Estimation during Resistance Spot Welding,” Welding Journal-New York-, Vol. 81, No. 6, pp. 104S–111S, 2002.

American National Standard, “Specification for Automotive Weld Quality -Resistance Spot Welding of Steel,” AWS D8.1M, 2007.

Zhang, H. and Senkara, J., “Resistance Welding: Fundamentals and Applications,” CRC Press, pp. 257–305, 2011.

ISO 14327, “Resistance Welding -Procedures for Determining the Weldability Lobe for Resistance Spot, Projection and Seam Welding,” 2004.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Yu, J. New methods of resistance spot welding using reference waveforms of welding power. Int. J. Precis. Eng. Manuf. 17, 1313–1321 (2016). https://doi.org/10.1007/s12541-016-0156-z

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12541-016-0156-z