Abstract

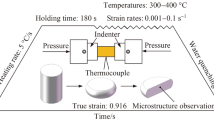

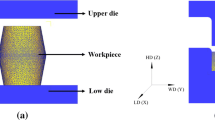

In this study, the hot deformation behavior of a magnesium alloy was investigated under various process conditions. Tensile testing experiments were performed to determine the effects of temperature, strain, and strain rate on the flow stress of the material. A new constitutive model was established to characterize the dynamic recrystallization of the magnesium alloy at elevated temperatures. The critical strain was evaluated based on the temperature-compensated strain rate to consider the work softening. The amount of high temperature softening due to dynamic recovery and dynamic recrystallization was formulated as a function of strain, strain rate, and temperature. It was demonstrated that the proposed model is able to predict the flow softening as well as the growing strain hardening of the material very accurately. The failure characteristics were also studied at different temperatures and strain rates. Finally, the grain size effect on the flow behavior of the material was discussed.

Similar content being viewed by others

References

Mordike, B. and Ebert, T., “Magnesium: Properties — Applications — Potential,” Materials Science and Engineering: A, Vol. 302, No. 1, pp. 37–45, 2001.

Polmear, I., “Magnesium Alloys and Applications,” Materials Science and Technology, Vol. 10, No. 1, pp. 1–16, 1994.

Nam, J. S., Lee, S. W., and Kim, H. S., “Investigations into the Size Effect on Plastic Deformation Behavior of Metallic Materials in Microcoining Process,” Int. J. Precis. Eng. Manuf., Vol. 15, No. 1, pp. 5–11, 2014.

Agnew, S. R. and Duygulu, Ö., “Plastic Anisotropy and the Role of Non-Basal Slip in Magnesium Alloy AZ31B,” International Journal of Plasticity, Vol. 21, No. 6, pp. 1161–1193, 2005.

Roberts, C. S., “Magnesium and Its Alloys,” John Wiley & Sons, pp. 81–107, 1960.

Changizian, P., Zarei-Hanzaki, A., and Roostaei, A. A., “The High Temperature Flow Behavior Modeling of AZ81 Magnesium Alloy Considering Strain Effects,” Materials and Design, Vol. 39, pp. 384–389, 2012.

Liu, J., Cui, Z., and Li, C., “Modelling of Flow Stress Characterizing Dynamic Recrystallization for Magnesium Alloy AZ31B,” Computational Materials Science, Vol. 41, No. 3, pp. 375–382, 2008.

Qin, Y. J., Pan, Q. L., He, Y. B., Li, W. B., Liu, X. Y., and Fan, X., “Modeling of Flow Stress for Magnesium Alloy during Hot Deformation,” Materials Science and Engineering: A, Vol. 527, No. 10, pp. 2790–2797, 2010.

Takuda, H., Morishita, T., Kinoshita, T., and Shirakawa, N., “Modelling of Formula for Flow Stress of a Magnesium Alloy AZ31 Sheet at Elevated Temperatures,” Journal of Materials Processing Technology, Vol. 164–165, pp. 1258–1262, 2005.

Ulacia, I., Salisbury, C., Hurtado, I., and Worswick, M., “Tensile Characterization and Constitutive Modeling of AZ31B Magnesium Alloy Sheet Over Wide Range of Strain Rates and Temperatures,” Journal of Materials Processing Technology, Vol. 211, No. 5, pp. 830–839, 2011.

Anaraki, M. T., Sanjari, M., and Akbarzadeh, A., “Modeling of High Temperature Rheological Behavior of AZ61 Mg-Alloy using Inverse Method and ANN,” Materials and Design, Vol. 29, No. 9, pp. 1701–1706, 2008.

Koike, J., Kobayashi, T., Mukai, T., Watanabe, H., Suzuki, M., and et al., “The Activity of Non-Basal Slip Systems and Dynamic Recovery at Room Temperature in Fine-Grained AZ31B Magnesium Alloys,” Acta Materialia, Vol. 51, No. 7, pp. 2055–2065, 2003.

Srinivasan, N., Prasad, Y., and Rama Rao, P., “Hot Deformation Behaviour of Mg-3Al Alloy — a Study using Processing Map,” Materials Science and Engineering: A, Vol. 476, No. 1, pp. 146–156, 2008.

Maksoud, I. A., Ahmed, H., and Rödel, J., “Investigation of the Effect of Strain Rate and Temperature on the Deformability and Microstructure Evolution of AZ31 Magnesium Alloy,” Materials Science and Engineering: A, Vol. 504, No. 1, pp. 40–48, 2009.

Hollomon, J. H., “The Mechanical Equation of State,” Trans AIME, Vol. 171, pp. 535–545, 1947.

Mwembela, A., Konopleva, E., and McQueen, H., “Microstructural Development in Mg Alloy AZ31 during Hot Working,” Scripta Materialia, Vol. 37, No. 11, pp. 1789–1795, 1997.

Petch, N. J., “The Cleavage Strength of Polycrystals,” Journal of the Iron and Steel Institute, Vol. 173, pp. 25–28, 1953.

Barnett, M. R., Keshavarz, Z., Beer, A. G., and Atwell, D., “Influence of Grain Size on the Compressive Deformation of Wrought Mg-3Al-1Zn,” Acta Materialia, Vol. 52, No. 17, pp. 5093–5103, 2004.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Shin, KH., Lee, YS. & Kim, H.S. The flow behavior modeling of AZ61 magnesium alloy at elevated temperatures considering the effects of strain rate and grain size. Int. J. Precis. Eng. Manuf. 15, 745–751 (2014). https://doi.org/10.1007/s12541-014-0395-9

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12541-014-0395-9