Abstract

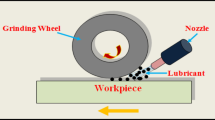

Nanofluid minimum quantity lubrication (MQL) technique has recently attained a significant attention for mechanical machining processes to reduce environmental loads caused by full usage of metal working fluids (MWF). Nanofluid refers to a fluid containing nanoparticles, which has superior lubrication and cooling characteristics. This paper investigates the characteristics of a nanofluid MQL micro-grinding process through a series of experiments. The miniaturized desktop machine tool system is developed, and a small grinding wheel is used to effectively realize the nanofluid MQL microgrinding process. Nanodiamond and nano-Al2O3 particles are selected, and the base fluid is paraffin oil. The experimental results show that nanofluid MQL is effective for reducing grinding forces and enhancing surface quality. In addition, it is demonstrated that the type, size and volumetric concentration of nanoparticles are critical parameters to have influence on the performances of micro-grinding process.

Similar content being viewed by others

References

Calvert, G. M., Ward, E., Schnorr, T. M. and Fine, L. J., “Cancer Risks Among Workers Exposed to Metalworking Fluids: a Systematic Review,” Am. J. Ind. Med., Vol. 33, No. 3, pp. 282–292, 1998.

Klocke, F. and Eisenblatter, G., “Dry cutting,” Annals of CIRP, Vol. 46, No. 2, pp. 519–526, 1997.

Braga, D. U., Diniz, A. E., Miranda, G. W. A. and Coppini, N. L., “Using a Minimum Quantity of Lubricant (MQL) and a Diamond Coated Tool in the Drilling of Aluminum-Silicon Alloys,” J. Mater. Process. Technol., Vol. 122, No. 1, pp. 127–138, 2002.

Hafenbraedle, D. and Malkin, S., “Environmentally-conscious Minimum Quantity Lubrication (MQL) for Internal Cylindrical Grinding,” Trans. NAMRI/SME, Vol. 28, pp. 149–154, 2000.

Hwang, Y. K., Lee, C. M. and Park, S. H., “Evaluation of Machinability According to the Changes in Machine Tools and Cooling Lubrication Environments and Optimization of Cutting Conditions Using Taguchi Method,” Int. J. Precis. Eng. Manuf., Vol. 10, No. 3, pp. 65–73, 2009.

Battez, A. H., Gonzalez, R., Viesca, J. L., Fernandez, J. E., Fernandez, J. M. D., Machado, A., Chou, R. and Riba, J., “CuO, ZrO2 and ZnO nanoparticles as antiwear additives in oil lubricants,” Wear, Vol. 265, No. 3–4, pp. 422–428, 2008.

Yu, W., Xie, H., Chen, L. and Li, Y., “Investigation of Thermal Conductivity and Viscosity of Ethylene Glycol Based ZnO Nanofluid,” Thermochimica Acta, Vol. 491, No. 1–2, pp. 92–96, 2009.

Moghadassi, A. R., Hosseini, S. M., Henneke, D. and Elkamel, A., “A Model of Nanofluid Effective Thermal Conductivity Based on Dimensionless Groups,” J. Therm. Anal. Calorim., Vol. 96, No. 1, pp. 81–84, 2009.

Hwang, Y., Park, H. S., Lee, J. K. and Jung, W. H., “Thermal Conductivity and Lubrication Characteristics of Nanofluids,” Current Applied Physics, Vol. 6S1, pp. e67–e71, 2006.

Ginzburg, B. M., Shibaev, L. A., Kireenko, O. F., Shepelevskii, A. A., Baidakova, M. V. and Sitnikova, A. A., “Antiwear Effect of Fullerene C60 Additives to Lubricating Oils,” Russian J. Appl. Chem., Vol. 75, No. 8, pp. 1330–1335, 2002.

Ku, B. C., Han, Y. C., Lee, J. E., Lee, J. K., Park, S. H. and Hwang, Y. J., “Tribological Effects of Fullerene (C60) Nanoparticles Added in Mineral Lubricants According to its Viscosity,” Int. J. Precis. Eng. Manuf., Vol. 11, No. 4, pp. 607–611, 2010.

Oh, S. M. and Rhee, B. G., “Effects of Tribological Characteristics on Lubricant Properties (The 2nd),” J. of the KSTLE, Vol. 17, No. 4, pp. 335–340, 2001.

Wang, Y., Fernandez, J. E. and Cuervo, D. G., “Rolling-Contact Fatigue Lives of Steel AISI 52100 Balls with Eight Mineral and Synthetic Lubricants,” Wear, Vol. 196, No. 1–2, pp. 110–119, 1996.

Shen, B., Malshe, A. P., Kalita, P. and Shih, A. J., “Performance of Novel MoS2 Nanoparticles Based Grinding Fluids in Minimum Quantity Lubrication Grinding,” Trans. NAMRI/SME, Vol. 36, pp. 357–364, 2008.

Shen, B., Shih, A. J. and Tung, S. C., “Application of Nanofluids in Minimum Quantity Lubrication Grinding,” Tribology Transactions, Vol. 51, No. 6, pp. 730–737, 2008.

Sridharan, U. and Malkin, S., “Effect of Minimum Quantity Lubrication (MQL) with Nanofluids on Grinding Behavior and Thermal Distortion,” Trans. NAMRI/SME, Vol. 37, pp. 629–636, 2009.

Kalita, P., Malshe, A. P., Jiang, W. and Shih, A. J., “Tribological Study of Nano Lubricant Integrated Soybean Oil for Minimum Quantity Lubrication (MQL) Grinding,” Trans. NAMRI/SME, Vol. 38, pp. 137–144, 2010.

Shankara, A., Menezes, P. L., Simha, K. R. Y. and Kailas, S. V., “Study of Solid Lubrication with MoS2 Coating in the Presence of Additives Using Reciprocating Ball-on-Flat Scratch Tester,” Sadhana, Vol. 33, No. 3, pp. 207–220, 2008.

Park, K. H., Shantanu, J., Kwon, P., Drazl, L. T. and Do, I., “Minimum Quantity Lubrication (MQL) with Nanographene Enhanced Lubrication: Ball-Milling Experiment,” Trans. NAMRI/SME, Vol. 38, pp. 81–88, 2010.

Jeng, H. A. and Swanson, J., “Toxicity of Metal Oxide Nanoparticles in Mammalian Cells,” J. Environ. Sci. Health A: Toxic/Hazardous Subst. Environ. Eng., Vol. 41, No. 12, pp. 2699–2711, 2006.

Schrand, A. M., Huang, H., Carlson, C., Schlager, J. J., Osawa, E., Hussain, S. M. and Dai, L., “Are Diamond Nanoparticles Cytotoxic?” J. Phys. Chem. B, Vol. 111, No. 1, pp. 2–7, 2007.

Navarro, E., Piccapietra, F., Wagner, B., Marconi, F., Kaegi, R., Odzak, N., Sigg, L. and Behra, R., “Toxicity of Silver Nanoparticles to Chlamydomonas Reinhardtii,” Environ. Sci. Technol., Vol. 42, No. 23, pp. 8959–8964, 2008.

Lee, C. G., Hwang, Y. J., Choi, Y. M., Park, M. C., Kim, K. M., Lee, J. K., Choi, C. and Oh, J. M., “The Comparison of Lubrication Characteristics on the Effects of the Size and Shape of the Nanoparticles Dispersed in Nano Lubricants,” Proc. of the KSTLE Spring Conf., pp. 140–145, 2008.

Lee, C. G., Hwang, Y. J., Choi, Y. M., Lee, J. K., Choi, C. and Oh, J. M., “A Study on the Tribological Characteristics of Graphite Nano Lubricants,” Int. J. Precis. Eng. Manuf., Vol. 10, No. 1, pp. 85–90, 2009.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Lee, PH., Nam, J.S., Li, C. et al. An experimental study on micro-grinding process with nanofluid minimum quantity lubrication (MQL). Int. J. Precis. Eng. Manuf. 13, 331–338 (2012). https://doi.org/10.1007/s12541-012-0042-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12541-012-0042-2