Abstract

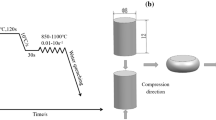

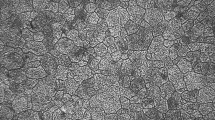

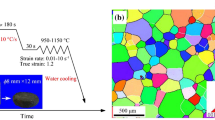

The hot deformation behavior of low-density high-strength Fe–Mn–Al–C alloy steel at T = 900-1150 °C and \(\dot{\varepsilon }\) = 0.01-10 s−1 was studied by the Gleeble-3500 thermo-mechanical simulator. The rheological stress curve characteristics of the steel were analyzed through experimental data, and a physical constitutive model considering strain coupling was established. At the same time, the finite element software DEFORM was used to calculate the critical damage value of the steel, and the influence of T and \(\dot{\varepsilon }\) on the maximum damage value was considered. By introducing the dimensionless parameter Zener–Hollomon, the critical damage model was established. Finally, the workability of the steel was evaluated by using the intuitive processing map technology. The results indicated that Fe–Mn–Al–C alloy steel is a positive strain rate-sensitive and a negative temperature-sensitive material, and the constitutive model considering physical parameters can well predict the rheological stress of the steel during hot deformation (R = 0.997). The critical damage factor of Fe–Mn–Al–C alloy steel varies with the change of T and \(\dot{\varepsilon }\), and the range is 0.359-0.535. At the same time, the critical damage factor is more sensitive to \(\dot{\varepsilon }\). At a constant T, the damage factor decreases with the increase of \(\dot{\varepsilon }\). Based on the Prasad instability criterion, the dynamic material model processing map and the microstructure verification after thermal compression, the rheological instability characteristics of the steel are mainly mechanical instability and local plastic flow, and the stable deformation area is mainly characterized by dynamic recrystallization. The optimal hot working process window of the steel is 975-1050 °C/0.01-0.032 s−1.

Graphical abstract

Similar content being viewed by others

References

C.M. Chu, H. Huang, P.W. Kao, D. Gan, Scripta Metall. Mater. 30, 505 (1994)

I. Zuazo, B. Hallstedt, B. Lindahl, M. Selleby, M. Soler, A. Etienne, A. Perlade, D. Hasenpouth, V. Massardier-Jourdan, S. Cazottes, X. Kleber, JOM 66, 1747 (2014)

S. Chen, R. Rana, A. Haldar, R.K. Ray, Prog. Mater Sci. 89, 345 (2017)

P. Ren, X.P. Chen, Z.X. Cao, L. Mei, W.J. Li, W.Q. Cao, Q. Liu, Mater. Sci. Eng. A 752, 160 (2019)

X. Chen, Q. Liao, Y. Niu, W. Jia, Q. Le, C. Cheng, F. Yu, J. Cui, J. Mater. Res. Technol. 8, 1859 (2019)

P. Liu, R. Zhang, Y. Yuan, C. Cui, Y. Zhou, X. Sun, J. Alloy. Compd. 831, 154618 (2020)

Q.G. Meng, C.G. Bai, D.S. Xu, J. Mater. Sci. Technol. 34, 679 (2018)

Y.H. Sun, R.C. Wang, J. Ren, C. Peng, Y. Feng, Mech. Mater. 131, 158 (2019)

R.H. Wu, Y. Liu, C. Geng, Q. Lin, Y. Xiao, J. Xu, W. Kang, J. Alloy. Compd. 713, 212 (2017)

J.L. Zhang, D. Raabe, C.C. Tasan, Acta Mater. 141, 374 (2017)

Z. Li, Y.C. Wang, X.W. Cheng, Z. Li, C. Gao, S. Li, Mater. Sci. Eng. A 822, 141683 (2021)

Y.B. Tan, Y.H. Ma, F. Zhao, J. Alloy. Compd. 741, 85 (2018)

M. Detrois, S. Antonov, S. Tin, Paul D. Jablonski, Jeffrey A. Hawk, Mater. Charact. 157, 109915 (2019)

Y.H. Han, C.S. Li, J.Y. Ren, C. Qiu, E. LI, S. Chen, Met. Mater. Int. 27, 3574 (2021)

Y.X. Chen, T. Li, Z.H. Gong, J.-Q. Zhao, G. Yang, J. Iron Steel Res. 32, 150 (2020)

H.L. Wei, G.Q. Liu, X. Xiao, M. Zhang, Acta Metall. Sin. 49, 731 (2013)

F.Q. Yang, Research on the preparation technology and deformation mechanism of automobile light-weight Fe-Mn-Al-C high strength steel, Ph.D. thesis, University of Science and Technology Beijing (2015)

H. Gwon, S. Shin, J. Jeon, T. Song, S. Kim, B.C. De Cooman, Met. Mater. Int. 25, 594 (2019)

H.J. Frost, M.F. Ashby, Deformation-Mechanism Maps: The Plasticity and Creep of Metals and Ceramics (Pergamon Press, Oxford, 1982)

C.Y. Lu, J. Shi, J. Wang, Mater. Charact. 181, 111455 (2021)

Z.W. Zhou, H.Y. Gong, J. You, S. Liu, J. He, Mater. Today Commun. 28, 102507 (2021)

Q.S. Dai, Y.L. Deng, J.G. Tang, Y. Wang, T. Nonferr. Metal. Soc. China 29, 2252 (2019)

M. Shalbafi, R. Roumina, R. Mahmudi, J. Alloy. Compd. 696, 1269 (2017)

R. Sowerby, N. Chandrasekaran, Mater. Sci. Eng. 79, 27 (1986)

G.Z. Quan, Y.X. Wang, Y.W. Zhang, F.B. Wang, L. Gao, J. Chongqing Univ. 34, 51 (2011)

G.Z. Quan, Y. Tong, J. Zhou, J. Funct. Mater. 41, 892 (2010)

Q. Zhang, Y.F. Fu, Hot Work. Technol. 42, 25 (2013)

J. Liu, P. Wang, Rare Metal Mat. Eng. 43, 2455 (2014)

M.-S. Chen, W.-Q. Yuan, Y.C. Lin, H.-B. Li, Z.-H. Zou, Vacuum 146, 142 (2017)

P. Wan, T. Kang, F. Li, P. Gao, L. Zhang, Z. Zhao, J. Mater. Res. Technol. 15, 1059 (2021)

G.-Z. Quan, G.-S. Li, Y. Wang, J. Zhou, P.-C. LI, Trans. Mater. Heat Treatment 34, 175 (2013)

P. Wan, H. Zou, K.L. Wang, Z.Z. Zhao, Met. Mater. Int. 27, 4235 (2021)

C. Zener, J.H. Hollomon, J. Appl. Phys. 15, 22 (1944)

Y. Wang, J. Li, Y. Xin, C. Li, Y. Cheng, X. Chen, M. Rashad, B. Liu, Y. Liu, Mater. Sci. Eng. A 768, 138483 (2019)

L. Li, Y. Wang, H. Li, W. Jiang, T. Wang, C.-C. Zhang, F.Wang, H. Garmestani, Comput. Mater. Sci. 166, 221 (2019)

E. Aryshenskii, J. Hirsch, V. Bazhin, R. Kawalla, U. Pral, T. Nonferr. Metal. Soc. China 29, 893 (2019)

C.M. Sellars, W.J. Mctegart, Acta Metall. 14, 1136 (1966)

Y.V.R.K. Prasad, H.L. Gegel, S.M. Doraivelu, J.C. Malas, J.T. Morgan, K.A. Lark, D.R. Barker, Metall. Trans. A 15, 1883 (1984)

L.Y. Ye, Y.W. Zhai, L.Y. Zhou, H. Wang, P. Jiang, J. Manuf. Process. 59, 535 (2020)

Y.V.R.K. Prasad, J. Mater. Eng. Perform. 12, 638 (2003)

Y.V.R.K. Prasad, T.Seshacharyulu, Mater. Sci. Eng. A 243, 82 (1998)

Z.-H. Zhang, Y.-N. Liu, X.-K. Liang, Y. She, Mater. Sci. Eng. A 474, 254 (2008)

H. Gwon, J.-K. Kim, B. Jian, H. Mohrbacher, T. Song, S.-K. Kim, B.C. De Cooman, Mater. Sci. Eng. A 711, 130 (2018)

J.X. Liu, H.B. Wu, S.W. Yang, X. Yu, C. Ding, Mater. Lett. 285, 128999 (2021)

P.L. Narayana, C.-L. Li, J.-K. Hong, S.-W. Choi, C.H. Park, S.-W. Kim, S.E. Kim, N.S. Reddy, J.-T. Yeom, Met. Mater. Int. 25, 1063 (2019)

Y.M. Huo, T. He, S.S. Chen, H. Ji, R. Wu, J. Manuf. Process. 44, 113 (2019)

Acknowledgements

This study was sponsored by the New Energy Automobile Material Production and Application Demonstration Platform Project (No. TC180A6MR-1) and the Key Research and Development Plan of Shandong Province (No. 2019TSLH0103).

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of interest

This authors declare no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Wan, P., Yu, H., Li, F. et al. Hot Deformation Behaviors and Process Parameters Optimization of Low-Density High-Strength Fe–Mn–Al–C Alloy Steel. Met. Mater. Int. 28, 2498–2512 (2022). https://doi.org/10.1007/s12540-021-01144-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12540-021-01144-x