Abstract

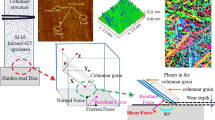

The present study aims at a detailed investigation of microstructure, residual stress and evaluation of microhardness of electron beam surface remelted Inconel 718 alloy using an indigenously developed electron beam welding unit (with a capacity of 80 kV acceleration voltage and a power of 12 kW). Electron beam surface remelting has been carried out at a constant voltage of 40 kV with varying scan speed from 500 to 1000 mm/min. The detailed study involves understanding of the effect of process parameters on the surface roughness, microstructure, residual stress, and hardness of the melt zone. Surface remelting leads to a significant refinement of microstructure with the presence of γ primary dendrites, fine precipitates of Ni3(Al,Ti) (γ′), and MC (metallic carbides). Due to microstructural refinement and presence of fine precipitates, there is an introduction of residual compressive stress and improvement in hardness. Finally, a detailed study of the effect of process parameters on the microstructure, residual stress and microhardness has been undertaken to optimize the process parameters for electron beam remelting of INCONEL718.

Graphical abstract

Similar content being viewed by others

References

E. Akca, A. Gursel, Period. Eng. Nat. Sci. 3, 15–27 (2013)

K. Zhao, Y.H. Ma, L.H. Lou, Z.Q. Hu, Mater. Sci. Eng. A 480, 205–208 (2008)

C. Slama, M. Abdellaoui, J. Alloys Compd. 306, 277–284 (2000)

L.A. Dobrzański, J. Mikuła, J. Mater. Process. Technol. 164–165, 822–831 (2005)

G. Muvvala, D. Patra Karmakar, A.K. Nath, Opt. Lasers Eng. 88, 139–152 (2017)

A. Lingenfelter, in Proceedings of the Conference on ‘Superalloy 718—Metallurgy and Applications. ed. by E.A. Loria (PA, TMS, Warrendale, 1989), pp. 673–683

S.G.K. Manikandan, D. Sivakumar, K.P. Rao, M. Kamaraj, J. Mater. Process. Technol. 214, 358–364 (2014)

S. Schiller, S. Panzer, Thin Solid Films 118, 85–92 (1984)

A. Strondl, M. Palm, J. Gnauk, G. Frommeyer, Mater. Sci. Technol. 0836, 876–883 (2011)

W.J. Sames, K.A. Unocic, R.R. Dehoff, T. Lolla, S.S. Babu, J. Mater. Res. 29, 1920–1930 (2014)

L.E. Murr, E. Martinez, S.M. Gaytan, D.A. Ramirez, B.I. Machado, L.E. Murr, E. Martinez, S.M. Gaytan, D.A. Ramirez, B.I. Machado, P.W. Shindo, J.L. Martinez, F. Medina, J. Wooten, D. Ciscel, U. Ackelid, R.B. Wicker, Metall. Mater. Trans. A 42, 3491–3508 (2011)

S. Basak, S.K. Sharma, K.K. Sahu, S. Gollapudi, J.D. Majumdar, SN Appl. Sci. 1, 744–750 (2019)

K.N. Amato, S.M. Gaytan, L.E. Murr, E. Martinez, P.W. Shindo, J. Hernandez, S. Collins, F. Medina, Acta Mater. 60, 2229–2239 (2012)

S. Guo, Q. Zhou, J. Kong, Y. Peng, Y. Xiang, T. Luo, K. Wang, J. Zhu, Vacuum 128, 205–212 (2016)

J. Kim, J. Kim, E. Kang, H. Wook, Appl. Surf. Sci. 311, 201–207 (2014)

K. Mumtaz, N. Hopkinson, Rapid Prototyp. J. 15, 96–103 (2009)

Y. Tian, D. Tomus, P. Rometsch, X. Wu, Addit. Manuf. 13, 103–112 (2017)

C.A. Huang, T.H. Wang, C.H. Lee, W.C. Han, Mater. Sci. Eng. A 398, 275–281 (2005)

S.K. Sharma, K. Biswas, J.D. Majumdar, Procedia Manuf. 35, 866–873 (2019)

B.S. Yilbas, H. Ali, N. Al-Aqeeli, C. Karatas, Opt. Laser Technol. 78, 153–158 (2016)

J.D. Majumdar, I. Manna, Mater. Sci. Eng. A 268, 216–226 (1999)

J.D. Majumdar, I. Manna, Mater. Sci. Eng. A 267, 50–59 (1999)

A.D. Patel, Y.V. Murty, Superalloys 718, 625, 706 and Various Derivatives (The Minerals, Metals & Materials Society, Warrendale, 2001), pp. 123–132

H.S. Choi, Ju Choi, J. Korean Nucl. Soc. 4, 203–213 (1972)

A. Strondl, R. Fischer, G. Frommeyer, A. Schneider, Mater. Sci. Eng. A 480, 138–147 (2008)

L. Wenchang, X. Furen, Y. Mei, C. Zonglin, W. Shaogang, L.I. Weihong, J. Mater. Sci. Lett 6, 769–771 (1997)

P.J. Withers, H.K.D.H. Bhadeshia, Mater. Sci. Technol. 17, 355–365 (2001)

P.J. Withers, H.K.D.H. Bhadeshia, Mater. Sci. Technol. 17, 366–375 (2001)

B.D. Cullity, S.S. R., Elements of X Ray Diffraction, Third, Edison (Wesley Publishing Company, Inc, Reading Massachusetts, 1956), pp. 122–134

M. Ahmad, J.I. Akhter, M.A. Shaikh, J. Alloys Compd. 422, 97–101 (2006)

Acknowledgements

Partial financial support from the Board of Research in Nuclear Science, Bombay for the present work is gratefully acknowledged. Characterization facilities extended by Central Research Facility, IIT Kharagpur are also gratefully acknowledged. Financial support from SERB, N. Delhi and Indian Space Rese arch Organization (ISRO) for the said work is gratefully acknowledged.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Sharma, S.K., Biswas, K. & Dutta Majumdar, J. Studies on Electron Beam Surface Remelted Inconel 718 Superalloy. Met. Mater. Int. 27, 5360–5373 (2021). https://doi.org/10.1007/s12540-020-00884-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12540-020-00884-6