Abstract

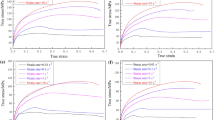

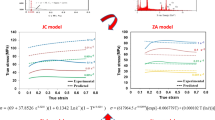

The flow behaviour of a ferritic stainless steel (FSS) was investigated by a Gleeble 3500 thermal-mechanical test simulator over the temperature range of 900–1100 °C and strain rate range of 1–50 s−1. Empirical and phenomenological constitutive models were established, and a comparative study was made on the predictability of them. The results indicate that the flow stress decreases with increasing the temperature and decreasing the strain rate. High strain rate may cause a drop in flow stress after a peak value due to the adiabatic heating. The Zener-Hollomon parameter depends linearly on the flow stress, and decreases with raising the temperature and reducing the strain rate. Significant deviations occur in the prediction of flow stress by the Johnson-Cook (JC) model, indicating that the JC model cannot accurately track the flow behaviour of the FSS during hot deformation. Both the multiple-linear and the Arrhenius-type models can track the flow behaviour very well under the whole hot working conditions, and have much higher accuracy in predicting the flow behaviour than that of the JC model. The multiple-linear model is recommended in the current work due to its simpler structure and less time needed for solving the equations relative to the Arrhenius-type model.

Similar content being viewed by others

References

J. K. L. Lai, C. H. Shek, and K. H. Lo, Stainless Steels: An Introduction and Their Recent Development, p. 8, Bentham Science Publishers, Sharjah (2012).

X. Cheng, Z. Jiang, D. Wei, J. Zhao, B. J. Monaghan, R. J. Longbottom, and L. Jiang, Surf. Coat. Technol. 258, 257 (2014).

X. Zhang, L. Fan, Y. Xu, J. Li, X. Xiao, and L. Jiang, Mater. Des. 65, 682 (2015). Fig. 16. Verification of the developed multiple-linear and Arrheniustype models by a new experimental result which has not been used for fitting analysis.

M. Alizadeh-Sh, S. P. H. Marashi, and M. Pouranvari, Mater. Des. 56, 258 (2014).

V. Villaret, F. Deschaux-Beaume, C. Bordreuil, S. Rouquette, and C. Chovet, J. Mater. Process. Technol. 213, 1538 (2013).

T. J. Park, J. P. Kong, S. H. Uhm, I. S. Woo, J. S. Lee, and C. Y. Kang, J. Mater. Process. Technol. 211, 415 (2011).

J. Zhao, H. Ding, W. Zhao, M. Huang, D. Wei, and Z. Jiang, Comput. Mater. Sci. 92, 47 (2014).

J. Zhao, H. Ding, Z. Jiang, D. Wei, and K. Linghu, Metall. Mater. Trans. A 45, 4932 (2014).

S. Saadatkia, H. Mirzadeh, and J. M. Cabrera, Mater. Sci. Eng. A 636, 196 (2015).

I. Mejia, F. Reyes-Calderon, and J. M. Cabrera, Mater. Sci. Eng. A 644, 374 (2015).

H. Mirzadeh, Mech. Mater. 85, 66 (2015).

J. Luo, M. Li, X. Li, and Y. Shi, Mech. Mater. 42, 157 (2010).

Q. C. Fan, X. Q. Jiang, Z. H. Zhou, W. Ji, and H. Q. Cao, Mater. Des. 65, 193 (2015).

J. Zhao, H. Ding, W. Zhao, and Z. Jiang, J. Alloy. Compd. 574, 407 (2013).

S. A. S. Vanini, M. Abolghasemzadeh, and A. Assadi, Metall. Mater. Trans. A 44, 3376 (2013).

S. V. Mehtonen, L. P. Karjalainen, and D. A. Porter, Mater. Sci. Eng. A 571, 1 (2013).

S. V. Mehtonen, L. P. Karjalainen, and D. A. Porter, Mater. Sci. Eng. A 607, 44 (2014).

F. Gao, Z. Liu, R. D. K. Misra, H. Liu, and F. Yu, Met. Mater. Int. 20, 939 (2014).

H. Honjo, M. Mikami, M. Yamaguchi, and H. Ishii, IHI Eng. Rev. 42, 32 (2009).

S. Mehtonen, The Behavior of Stabilized High-Chromium Ferritic Stainless Steels in Hot Deformation, p. 84, University of Oulu, Oulu (2014).

J. Yan, Q. L. Pan, B. Li, Z. Q. Huang, Z. M. Liu, and Z. M. Yin, J. Alloy. Compd. 632, 549 (2015).

J. C. Hu, H. M. Song, M. Yu, and L. Z. Jiang, J. Iron Steel Res. Int. (Supplement 1) 14, 183 (2007).

L. Samek, E. De Moor, J. Penning, and B. C. De Cooman, Metall. Mater. Trans. A 37, 109 (2006).

D. N. Zou, Y. Han, D. N. Yan, D. Wang, W. Zhang, and G. W. Fan, Mater. Des. 32, 4443 (2011).

Y. Han, G. Qiao, J. Sun, and D. Zou, Comput. Mater. Sci. 67, 93 (2013).

J. Liu, H. Chang, R. Wu, T. Y. Hsu, and X. Ruan, Mater. Charact. 45, 175 (2000).

Z. Xu and F. Huang, Acta Mech. Solida Sin. 25, 598 (2012).

G. R. Johnson and W. H. Cook, Proceedings of the Seventh International Symposium on Ballistic, pp. 541–547, The Hague, The Netherlands (1983).

Z. Akbari, H. Mirzadeh, and J. M. Cabrera, Mater. Des. 77, 126 (2015).

M. A. Meyers and K. K. Chawla, Mechanical Behavior of Materials, 2nd ed., p. 384, Cambridge University Press, UK (2009).

R. Liang and Z. Khan, Int. J. Plast. 15, 963 (1999).

E. P. Chen, Special Steel 13, 28 (1992).

Y. C. Lin, Q. F. Li, Y. C. Xia, and L. T. Li, Mater. Sci. Eng. A 534, 654 (2012).

H. Shin and J. B. Kim, J. Eng. Mater. Technol. 132, 021009 (2010).

D. C. Montgomery and G. C. Runger, Applied Statistics and Probability for Engineers, 5th ed., p. 449, John Wiley & Sons, Inc., Manhattan (2010).

C. M. Sellars and W. J. McTegart, Acta Metall. 14, 1136 (1966).

S. Wang, L. G. Hou, J. R. Luo, J. S. Zhang, and L. Z. Zhuang, J. Mater. Process. Technol. 225, 110 (2015).

J. W. Zhao, H. Ding, H. L. Hou, and Z. Q. Li, J. Alloy. Compd. 491, 673 (2010).

D. Samantaray, S. Mandal, and A. K. Bhaduri, Comput. Mater. Sci. 47, 568 (2009).

J. W. Zhao, H. Ding, Y. Q. Wang, and H. L. Hou, Trans. Nonferrous Met. Soc. China 19, 65 (2009).

C. Zener and J. H. Hollomon, J. Appl. Phys. 15, 22 (1944).

F. Pilehva, A. Zarei-Hanzaki, S. M. Fatemi-Varzaneh, and A. R. Khalesian, J. Mater. Eng. Perform. 24, 1799 (2015).

H. Y. Wu, F. J. Zhu, S. C. Wang, W. R. Wang, C. C. Wang, and C. H. Chiu, J. Mater. Sci. 47, 3971 (2012).

L. Tang and J. D. Baeder, SIAM J. Sci. Comput. 20, 1115 (1998).

S. Asgari, E. El-Danaf, S. R. Kalidindi, and R. D. Doherty, Metall. Mater. Trans. A 28, 1781 (1997).

S. V. Mehtonen, E. J. Palmiere, R. D. K. Misra, L. P. Karjalainen, and D. A. Porter, Mater. Sci. Eng. A 601, 7 (2014).

R. Z. Wang and T. C. Lei, Scr. Metall. Mater. 31, 1193 (1994).

G. Glover and C.M. Sellars, Metall. Trans. A 4, 765 (1973).

H. Yagi, N. Tsuji, and Y. Saito, Tetsu-to-Hagane, 86, 349 (2000).

D. Raabe and K. Lüucke, Mater. Sci. Technol. 9, 302 (1993).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Zhao, J., Jiang, Z., Zu, G. et al. Flow behaviour and constitutive modelling of a ferritic stainless steel at elevated temperatures. Met. Mater. Int. 22, 474–487 (2016). https://doi.org/10.1007/s12540-016-5541-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12540-016-5541-8