Abstract

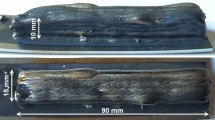

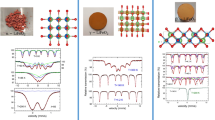

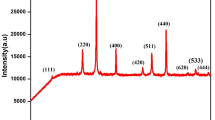

In this paper, an attempt has been made to synthesis of the nanostructured Ni47Mn40Sn13 ferromagnetic shape memory alloy by ball milling of Ni, Mn and Sn powder mixture. The structure and magnetic evaluation of samples were investigated by X-ray diffraction, transmission electron microscopy, differential scanning calorimetry and AC susceptibility measurements. The results showed that after 20 hours of ball milling, the nanostructured L21-Ni47Mn40Sn13 powder was formed with an average particle size of 5 nm. In the as-milled specimen, the martensitic transformation (MT) was not observed. This was basically due to the atomic disordering and large lattice strain in nanoparticles. However, the annealing of milled specimens at temperatures above 1023K for 16 hours led to the occurrence of MT in nanostructured Ni47Mn40Sn13 powders. We also calculated t-he activation energy of MT by using Kissinger method and it was estimated to be about 52 kJ mol−1. The results demonstrate that a combination of MA and subsequent heat treatment has the potential to produce Ni-Mn-Sn magnetic shape memory.

Similar content being viewed by others

References

R. Kainuma, Y. Imano, W. Ito, Y. Sutou, H. Morito, S. Okamoto, O. Kitakami, K. Oikawa, A. Fujita, and T. Kanomata, Nature 439, 957(2006).

Y. Sutou, Y. Imano, N. Koeda, T. Omori, R. Kainuma, K. Ishida, and K. Oikawa, Appl. Phys. Lett. 85, 4358 (2004).

O. Heczko and L. Straka, Mater. Sci. Eng. A 378, 394 (2004).

T. Krenke, E. Duman, M. Acet, E. F. Wassermann, X. Moya, L. Mañosa, and A. Planes, Nat. Mater. 4, 450 (2005).

R. Saha and A. K. Nigam, Physica B 448, 263 (2014).

Z. Liu, Z. Wu, X. Ma, W. Wang, Y. Liu, and G. Wu, J. Appl. Phys. 110, 013916 (2011).

S. Yu, L. Ma, G. Liu, Z. Liu, J. Chen, Z. Cao, G. Wu, B. Zhang, and X. Zhang, Appl. Phys. Lett. 90, 242501 (2007).

W. Cai, L. Gao and Z. Gao, J. Mater. Sci. 42, 9216 (2007).

T. Krenke, E. Duman, M. Acet, X. Moya, L. Mañosa, and A. Planes, J. Appl. Phys. 102, 033903 (2007).

R. Das, A. Perumal, and A. Srinivasan, Physica B 448, 327 (2014).

L. Mañosa, D. González-Alonso, A. Planes, E. Bonnot, M. Barrio, J.-L. Tamarit, S. Aksoy, and M. Acet, Nat. Mater. 9, 478 (2010).

V. Sánchez-Alarcos, J. Pérez-Landazábal, V. Recarte, I. Lucia, J. Vélez, and J. Rodríguez-Velamazán, Acta Mater. 61, 4676 (2013).

Q. Meng, Y. Rong, and T. Hsu, Phys. Rev. B 65, 174118 (2002).

B. Tian, F. Chen, Y. Tong, L. Li, Y. Zheng, Y. Liu, and Q. Li, J. Alloys Compd. 509, 4563 (2011).

B. Tian, F. Chen, Y. Liu, and Y. Zheng, Intermetallics 16, 1279 (2008).

Q. Tao, Z. Han, J. Wang, B. Qian, P. Zhang, X. Jiang, D. Wang, and Y. Du, AIP Advances 2, 042181 (2012).

H. Zheng, W. Wang, S. Xue, Q. Zhai, J. Frenzel, and Z. Luo, Acta Mater. 61, 4648 (2013).

S. E. Muthu, N. R. Rao, M. M. Raja, D. R. Kumar, D. M. Radheep, and S. Arumugam, J. Phys. D: Appl. Phys. 43, 425002 (2010).

A. Planes, L. Manosa, and M. Acet, J. Phys.: Condens. Matter 21, 233201 (2009).

T. Waitz, V. Kazykhanov, and H. Karnthaler, Acta Mater. 52, 137 (2004).

H. Xuan, K. Xie, D. Wang, Z. Han, C. Zhang, B. Gu, and Y. Du, Appl. Phys. Lett. 92, 242506 (2008).

S. Ma, H. Xuan, C. Zhang, L. Wang, Q. Cao, D. Wang, and Y. Du, Appl. Phys. Lett. 97, 052506 (2010).

H. Xuan, Y. Deng, D. Wang, C. Zhang, Z. Han, and Y. Du, J. Phys. D: Appl. Phys. 41, 215002 (2008).

Z. Ren, S. Li, and H. Luo, Physica B 405, 2840 (2010).

D. Cong, S. Roth, and L. Schultz, Acta Mater. 60, 5335 (2012).

M. Kök and Y. Aydogdu, Thermochim. Acta 548, 51 (2012).

H. E. Kissinger, Anal. Chem. 29, 1702 (1957).

H. Zheng, D. Wu, S. Xue, J. Frenzel, G. Eggeler, and Q. Zhai, Acta Mater. 59, 5692 (2011).

S. Dwevedi, J. Alloys Compd. 574, 188 (2013).

H. Xuan, S. Ma, Q. Cao, D. Wang, and Y. Du, J. Alloys Compd. 509, 5761 (2011).

M. Ye, A. Kimura, Y. Miura, M. Shirai, Y. Cui, K. Shimada, H. Namatame, M. Taniguchi, S. Ueda, and K. Kobayashi, Phys. Rev. Lett. 104, 176401 (2010).

A. Vasiliev, O. Heczko, O. Volkova, T. Vasilchikova, T. Voloshok, K. Klimov, W. Ito, R. Kainuma, K. Ishida, and K. Oikawa, J. Phys. D: Appl. Phys. 43, 055004 (2010).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Ghotbi Varzaneh, A., Kameli, P., Zahedi, V.R. et al. Effect of heat treatment on martensitic transformation of Ni47Mn40Sn13 ferromagnetic shape memory alloy prepared by mechanical alloying. Met. Mater. Int. 21, 758–764 (2015). https://doi.org/10.1007/s12540-015-4537-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12540-015-4537-0