Abstract

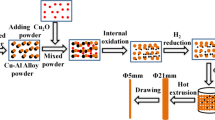

In this work, an Al/Cu composite was fabricated using repeated hydrostatic extrusions with a semi-die angle of 45° at a temperature of 200°C. During the repeated hydrostatic extrusion process, an intermetallic layer of 1 μm was generated at the Al/Cu interface. The intermetallic reinforcement layer formation was studied via field emission scanning electron microscopy, energy-dispersive X-ray spectroscopy, and transmission electron microscopy. The reinforcement layers consisted of Al2Cu and Al4Cu9 phases. The thermal conductivity and coefficient of thermal expansion of the Al/Cu composites were determined via laser flash analyzer and thermal mechanical analyzer. The thermal conductivities in the longitudinal direction and cross direction were 267.8 W/mK and 209.9 W/mK at room temperature, respectively. The coefficient of thermal expansion at temperatures between room temperature and 450°C was 18.3 μm/m°C. The ultimate tensile strength of the Al/Cu composite is 102.8 MPa. The anisotropic physical properties of the prepared composite were mainly a result of the unique directional microstructure formed during the repeated extrusion process.

Similar content being viewed by others

References

Y. M. Jo, K. S. Lee, N. H. Kang, and Y. S. Lee, Korean J. Met. Mater. 52, 881 (2014).

P. C. Tortorici and M. A. Dayananda, Mater. Sci. Eng. 244, 207 (1998).

K. Osakada, M. Limb, and P. B. Mellor, Int. J. Mech. Sci. 15, 291 (1973).

H. J. Park, K. H. Na, N. S. Cho, Y. S. Lee, and S. W. Kim, J. Mater. Process. Technol. 67, 24 (1997).

Y. Lu, J. H. Gu, S. S. Kim, H. U. Hong, H. K. Choi, and J. H. Lee, Met. Mater. Int. 20, 221 (2014).

D. G. Li, Q. Wang, T. Liu, G. J. Li, and J. C. He, Mater. Chem. Phys. 117, 504 (2009).

E. Hug and N. Bellido, Mater. Sci. Eng. 528, 7103 (2011).

P. Kova, W. Pachla, I. Husek, M. Kulczyk, T. Melisek, T. Holubek, R. Diduszko, and M. Reissner, Physica C. 468, 2356 (2008).

E. C. Moreno-Valle, W. Pachla, M. Kulczyk, B. Savoini, M. A. Monge, C. Ballesteros, and I. Sabirov, Mater. Sci. Eng. 588, 7 (2013).

H. G. Jeong, D. J. Yoon, E. Z. Kim, H. J. Park, and K. H. Na, J. Mater. Process. Technol. 130, 438 (2002).

Y. H. Park and C. Y. Kang, Korean Weld. Join. Soc. 24, 355 (2006).

J. Pilling and N. Rediely, J. Mater. Sci. Eng. 407, 154 (2005).

T. H. Lee, Y. J. Lee, K. T. Park, H. H. Nersisyan, H. G. Jeong, and J. H. Lee, J. Mater. Process. Technol. 213, 487 (2013).

H. C. Youn, S. M. Bak, S. H. Park, S. B. Yoon, K. C. Roh, and K. B. Kim, Met. Mater. Int. 20, 975 (2014).

R. A. Vandermeer, Acta Metallurgica, 15, 447 (1967).

Y. F. Li, J. T. Guo, and Y. F. Shen, Trans. Nonferrous Met. Soc. China, 16, 368 (2006).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Lee, TH., Lee, YJ., Park, KT. et al. Mechanical and asymmetrical thermal properties of Al/Cu composite fabricated by repeated hydrostatic extrusion process. Met. Mater. Int. 21, 402–407 (2015). https://doi.org/10.1007/s12540-015-4242-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12540-015-4242-z