Abstract

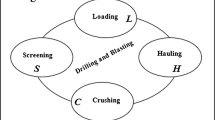

The fragmentation rate and particle size distribution of the muckpile after blasting have important influences on the performance of subsequent mining activities such as loading, hauling, crushing, grinding, and the overall costs of the mine. Drilling and blasting are important steps in the chain of mining processes, and its results affect the efficiency of downstream processes accordingly. There is an increasing body of blasting research that indicates the significant impacts in mining downstream processes. Within the scope of this study, a series of blasts were conducted in a sandstone quarry, and the throughput of the jaw crusher was recorded after each blasted rocks are fed. These measurements consisted of analysis of the particle size distribution of each muckpile after shots, and the assessment of particle size distributions of each truck—load fragmented rock. Digital image processing method was used for the assessment of the particle size distribution of blasted rock. The fragmentation results then were paired with the crusher throughput values, and series of regression analysis were done in order to understand the effects of blast fragmentation on crusher throughput. The analysis includes the relationship between P20, P50, P80, and Ptop values of size distributions and the crusher throughput results. Depending on the correlation degree of each relationship, effects of each size distribution parameter on crushing performance were discussed. Established empirical equations with reliable correlation coefficients can be used to estimate the crusher performance depending on fragmentation results of a blast and therefore, and blast designs can also be modified.

Similar content being viewed by others

References

Beke B (1964) Principles of comminution. Akademiai Kiado, Budapest

Beyglou A, Johansson D, Schunnesson H (2017) Target fragmentation for efficient loading and crushing -the Aitik case. J South Afr Inst Min Metall 117(11):1053–1062

Donovan JG (2003) Fracture toughness based models for the prediction of power consumption, product size and capacity of jaw crushers, PhD. Dissertation, Virginia Polytechnic Institute, USA

Duthoit V (2000) Aggregates, ch. 9 (edited by Louis Primel and Claude Tourenq) Crushing and Grinding Balkema, Rotterdam

Elahi AT, Hosseini M (2017) Analysis of blasted rocks fragmentation using digital image processing (case study: limestone quarry of Abyek Cement Company). Int J Geo-Eng 8:16. https://doi.org/10.1186/s40703-017-0053-z

Hofler A (1990) Fundamental breakage studies of mineral particles with an ultrafast load cell device, PhD Dissertation. University of Utah, Salt Lake City

Janaka GHA, Kumara J, Hayano K, Ogiwara K (2012) Image analysis techniques on evaluation of particle size distribution of gravel. Int J Geomate 3(1 Sl.5):290–297 Geotec., Const. Mat. & Env., ISSN:2186-2982(P), 2186-2990 (O)

Katsabanis PD (2020) Analysis of the effects of blasting on comminution using experimental results and numerical modelling. Int J Rock Mech Rock Eng 53:3093–3109. https://doi.org/10.1007/s00603-020-02093-4

King RP (2001) Modelling and simulation of mineral processing systems. Butterworth-Heinemann, Boston

Kursun İ (2009) Particle size and shape characteristics of kemerburgaz quartz sands obtained by sieving, laser diffraction, and digital image processing methods. Miner Process Extr Metall Rev 30(4):346–360. https://doi.org/10.1080/08827500903149659

McKee DJ, Chitombo GP, Morrell S (1995) The relationship between fragmentation in mining and comminution circuit throughput. Minerals Engineering, ol.8. No 11:1265–1274

Murr, D.L., Workman, L., Eloranta, J., and Katsabanis, T. (2015) Blasting influence on comminution. Proceedings of the Sixth International Conference on Semi-autogenous and High Pressure Grinding Technology, Vancouver

NACE, (2008) Catalogue of jaw crushers

Napier-Munn TJ, Morrell S, Morrison RD, Kojovic T (1999) Mineral comminution circuits – their operation and optimization. Julius Kruttschnitt Mineral Research Center, Queensland

Nielsen K, Kristiansen J (1996) Blasting-crushing-grinding: optimisation of an integrated comminution system. In: Proceedings of Fragblast, 5th edn. Fragmentation by Blasting, Montreal, pp 269–277

Ozdemir K (2009) Investigating the effects of particle size distribution on bench blasting to consecutive mining activities. PhD. Dissertation, Istanbul University, Turkey

Ozdemir K, Kahriman A, Karadoğan A, Tuncer G (2003) Blast fragmentation assessment and control using the split digital image analysis system. In: International Conference on Earth Sciences and Electronics (ICESE-2003). Istanbul University, Avcılar, Istanbul, Turkey

Ozdemir K, Tuncer G, Kahriman A, Ozer U, Karadogan A (2007a) The relation between excavator bucket loading time and particle size distribution of shot rock. Proceedings of The 33rd Annual Conference on Explosives and Blasting Technique, Nashville, Tennessee, Volume I, pp. 303-313

Ozdemir, K., Kahriman, A., Özer, U., Tuncer, G (2007b) Bench blasting optimization method depending on desired fragmentation, 7th International Conference: Modern Management of Mine Producing Geology and Environment Protection, Varna, Bulgaria

Sanchidrian JA, Segarra P, Lopez LM (2006) A practical procedure for the measurement of fragmentation by blasting by image analysis. Rock Mech Eng 39(4):359–382. https://doi.org/10.1007/s00603-005-0073-4

Sanchidrianan JA, Ouchterlony F, Moser P, Segarra P, Lopez LM (2012) Performance of some distributions to describe rock fragmentation data. Int J Rock Mech Min Sci 53:18–31

Sereshki F, Hoseini SM, Ataei M (2016) Blast fragmentation analysis using image processing. IJMGE 50(2):211–218. https://doi.org/10.22059/ijmge.2016.59831

Weiss NL (1985) Jaw crushers. In: Weiss NL (ed) SME Mineral Processing Handbook, ch. 3B-1 edn. SME/AIME, New York

Whittles DN, Kingman S, Lowndes I, Jackson K (2006) Laboratory and numerical investigation into the characteristics of rock fragmentation. Miner Eng 19:1418–1429. https://doi.org/10.1016/j.mineng.2006.02.004

Workman L, Eloranta J (2003) Effects of blasting on crushing and grinding efficiency and energy consumption. In: Int. Annual Conference on Explosives and Blasting Technique. Proceedings, Nashville

Acknowledgments

The authors would like to thank Istanbul University-Cerrahpasa Engineering Faculty, Executive Secretariat of Scientific Research Projects.

Funding

This work was financially supported by the Executive Secretariat of Scientific Research Projects of Istanbul University-Cerrahpasa with project number T-73/15122006.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The author declares no competing interests.

Additional information

Responsible Editor: Murat Karakus

Rights and permissions

About this article

Cite this article

Ozdemir, K. Evaluation of blast fragmentation effects on jaw crusher throughput. Arab J Geosci 14, 2036 (2021). https://doi.org/10.1007/s12517-021-08426-z

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s12517-021-08426-z