Abstract

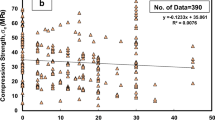

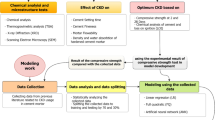

Advances in technology and environmental issues enable the building industry to use ever more high-performance materials. In this analysis, the hardness of cement mortar with high-volume silica fume has been evaluated and modeled using different model technics. Cement is an essential component of building construction. Physical and mechanical properties of cement mortar, as well as an appropriate design, are accountable for building mechanical strength. To overcome the mentioned matter, this study aims to establish systematic multiscale models to predict the compressive strength of cement mortar containing a high volume of silica fume (SF) and to be used by the construction industry with no theoretical restrictions. For that purpose, a wide experimental data (a total of 450 tested cement mortar modified with SF) from different academic research studies have been statically analyzed and modeled. For that purpose, linear and nonlinear regression, M5P tree, and artificial neural network (ANN) technical approaches were used for the qualifications. In the modeling process, most relevant parameters affecting the strength of cement mortar are silica fume (SF) incorporation ratio (0–50% of cement’s mass), water-to-cement ratio (0.235–1.2), and curing ages (1 to 180 days). According to the correlation coefficient (R), mean absolute error (MAE), and root mean a square error (RMSE), the compressive strength of cement mortar can be well predicted in terms of w/c, silica fume, and curing time using various simulation techniques. Among the used approaches and based on the training data set, the model made based on the nonlinear regression, ANN, and M5P tree models seem to be the most reliable models. The results of this study suggest that the nonlinear regression-based model (NLR) and ANN are performing better than other applied models using training and testing datasets. The sensitivity investigation concludes that the curing time is the most dominating parameter for the prediction of the compressive strength of cement mortar with this data set.

Similar content being viewed by others

Data availability

No data, models, or codes were generated or used during the study.

References

Abdalla LB, Ghafor K, Mohammed A (2019) Testing and modeling the young age compressive strength for high workability concrete modified with PCE polymers. Results Mater 1:100004

Aköz F, Türker F, Koral S, Yüzer N (1999) Effects of raised temperature of sulfate solutions on the sulfate resistance of mortars with and without silica fume. Cem Concr Res 29(4):537–544

Al-Khalaf MN, Yousif HA (1984) Use of rice husk ash in concrete. Int J Cem Compos Light Concr 6(4):241–248

Almeida AEDS, Sichieri EP (2007) Experimental study on polymer-modified mortars with silica fume applied to fix porcelain tile. Build Environ 42(7):2645–2650

Alwash JJH (2013) Use of rice husk ash in cement mortar. J Univ Babylon 21(2):582–590

Biricik H, Sarier N (2014) Comparative study of the characteristics of nano silica-, silica fume-and fly ash-incorporated cement mortars. Mater Res 17(3):570–582

Burhan L, Ghafor K, Mohammed A (2019) Modeling the effect of silica fume on the compressive, tensile strengths and durability of NSC and HSC in various strength ranges. J Build Pathol Rehabil 4(1):19

Çakır Ö, Sofyanlı ÖÖ (2015) Influence of silica fume on mechanical and physical properties of recycled aggregate concrete. HBRC J 11(2):157–166

Cong X, Gong S, Darwin D, McCabe SL (1990) Role of silica fume in compressive strength of cement paste, mortar, and concrete. University of Kansas Center for Research, Inc

De Rojas MS, Frías M (1996) The pozzolanic activity of different materials, its influence on the hydration heat in mortars. Cem Concr Res 26(2):203–213

Demir İ, Güzelkücük S, Sevim Ö (2018) Effects of sulfate on cement mortar with hybrid pozzolan substitution. Eng Sci Technol Int J 21(3):275–283

Demircan E, Harendra S, Vipulanandan C (2011) Artificial neural network and nonlinear models for gelling time and maximum curing temperature rise in polymer grouts. J Mater Civ Eng 23(4):372–377

Erdem RT, Ozturk AU, Gücüyen E (2016) Estimarea rezistentei la compresune a mortarelor de cement/estimation of compressive strength of cement mortars. Rev Romana Mater 46(3):313

Ghafor K, Qadir S, Mahmood W, Mohammed A (2020) Statistical variations and new correlation models to predict the mechanical behaviour of the cement mortar modified with silica fume. Geomech Geoeng 1:–13

Haach VG, Vasconcelos G, Lourenço PB (2011) Influence of aggregates grading and water/cement ratio in workability and hardened properties of mortars. Constr Build Mater 25(6):2980–2987

Huang CH, Lin SK, Chang CS, Chen HJ (2013) Mix proportions and mechanical properties of concrete containing very high-volume of Class F fly ash. Constr Build Mater 46:71–78

Huang J, Asteris PG, Pasha SMK, Mohammed AS, Hasanipanah M (2020) A new auto-tuning model for predicting the rock fragmentation: a cat swarm optimization algorithm. Eng Comput:1–12

Jia L, Zhang L, Guo J, Yao K, Lim SM, Li B, Xu H (2019) Evaluation on strength properties of lime–slag stabilized loess as pavement base material. Sustainability 11(15):4099

Jiang C, Zhou X, Huang S, Chen D (2016) Influence of polyacrylic ester and silica fume on the mechanical properties of mortar for repair application. Adv Mech Eng 9(1):1687814016683856

Jo BW, Kim CH, Tae GH, Park JB (2007) Characteristics of cement mortar with nano-SiO2 particles. Constr Build Mater 21(6):1351–1355

Jung SH, Kwon SJ (2013) Engineering properties of cement mortar with pond ash in South Korea as construction materials: from waste to concrete. Cent Eur J Eng 3(3):522–533

Mehta PK (2004) High-performance, high-volume fly ash concrete for sustainable development. In: Proceedings of the international workshop on sustainable development and concrete technology. Iowa State University, Ames, pp 3–14

Mishra S, Deodhar SV (2013) Effect of rice husk ash on cement mortar and concrete

Mohamadien HA (2012) The effect of marble powder and silica fume as partial replacement for cement on mortar. Int J Civ Struct Eng 3(2):418

Mohammed AS (2017) Effect of temperature on the rheological properties with shear stress limit of iron oxide nanoparticle modified bentonite drilling muds. Egypt J Pet 26(3):791–802

Mohammed AS (2018a) Vipulanandan models to predict the electrical resistivity, rheological properties and compressive stress-strain behavior of oil well cement modified with silica nanoparticles. Egypt J Pet 27(4):1265–1273

Mohammed AS (2018b) Property correlations and statistical variations in the geotechnical properties of (CH) clay soils. Geotech Geol Eng 36(1):267–281

Mohammed AS (2018c) Electrical resistivity and rheological properties of sensing bentonite drilling muds modified with lightweight polymer. Egypt J Pet 27(1):55–63

Mohammed AS (2018d) Vipulanandan model for the rheological properties with ultimate shear stress of oil well cement modified with nanoclay. Egypt J Pet 27(3):335–347

Mohammed AS (2019) Vipulanandan models to predict the mechanical properties, fracture toughness, pulse velocity and ultimate shear strength of shale rocks. Geotech Geol Eng 37(2):625–638

Mohammed A, Mahmood W (2018) Vipulanandan failure models to predict the tensile strength, compressive modulus, fracture toughness and ultimate shear strength of calcium rocks. Int J Geotech Eng:1–11

Mohammed A, Mahmood W (2019a) New Vipulanandan p-q model for particle size distribution and groutability limits for sandy soils. J Test Eval 48(5)

Mohammed A, Mahmood W (2019b) Estimating the efficiency of the sandy soils-cement based grout interactions from particle size distribution (PSD). Geomech Geoeng:1–18

Mohammed AS, Vipulanandan C (2014) Compressive and tensile behavior of polymer treated sulfate contaminated CL soil. Geotech Geol Eng 32(1):71–83

Mohammed A, Vipulanandan C (2015) Testing and modeling the short-term behavior of lime and fly ash treated sulfate contaminated CL soil. Geotech Geol Eng 33(4):1099–1114

Mohammed A, Vipulanandan C (2018) Smart cement compressive piezoresistive, stress-strain, and strength behavior with nanosilica modification. J Test Eval 47(2)

Mohammed A, Burhan L, Ghafor K, Sarwar W, Mahmood W (2020a) Artificial neural network (ANN), M5P-tree, and regression analyses to predict the early age compression strength of concrete modified with DBC-21 and VK-98 polymers. Neural Comput Appli:1–23

Mohammed A, Rafiq S, Sihag P, Kurda R, Mahmood W (2020b) Soft computing techniques: systematic multiscale models to predict the compressive strength of HVFA concrete based on mix proportions and curing times. J Build Eng:101851

Mohammed A, Rafiq S, Sihag P, Kurda R, Mahmood W, Ghafor K, Sarwar W (2020c) ANN, M5P-tree and nonlinear regression approaches with statistical evaluations to predict the compressive strength of cement-based mortar modified with fly ash. J Mater Res Technol 9(6):12416–12427

Mohammed A, Mahmood W, Ghafor K (2020d) TGA, rheological properties with maximum shear stress and compressive strength of cement-based grout modified with polycarboxylate polymers. Constr Build Mater 235:117534

Murlidhar BR, Bejarbaneh BY, Armaghani DJ, Mohammed AS, Mohamad ET (2020) Application of tree-based predictive models to forecast air overpressure induced by mine blasting. Nat Resour Res:1–23

Muttar AA, Salman MM (2011) Mechanical properties of acrylic mortar. J Eng Sustain Dev 15(3):152–162

Pereira MV, Fujiyama R, Darwish F, Alves GT (2015) On the strengthening of cement mortar by natural fibers. Mater Res 18(1):177–183

Qadir W, Ghafor K, Mohammed A (2019a) Characterizing and modeling the mechanical properties of the cement mortar modified with fly ash for various water-to-cement ratios and curing times. Adv Civ Eng. https://doi.org/10.1155/2019/7013908

Qadir W, Ghafor K, Mohammed A (2019b) Regression analysis and Vipulanandan model to quantify the effect of polymers on the plastic and hardened properties with the tensile bonding strength of the cement mortar. Results Mater:100011

Qadir W, Ghafor K, Mohammed A (2019c) Evaluation the effect of lime on the plastic and hardened properties of cement mortar and quantified using Vipulanandan model. Open Eng 9(1):468–480

Rai B, Kumar S, Satish K (2014) Effect of fly ash on mortar mixes with quarry dust as fine aggregate. Adv Mater Sci Eng 2014:1–7

Rathish KP (2010) High performance superplasticized silica fume mortars for ferrocement works. Facta Univ-Ser Archit Civ Eng 8(2):129–134

Ravichandran Y, Balasubramanian M (2014) Effect of processed fly ash on cement mortar for standard fine and normal sand. J Civ Eng Environ Technol 1(1):001–004

Reddy BV, Gupta A (2008) Influence of sand grading on the characteristics of mortars and soil–cement block masonry. Constr Build Mater 22(8):1614–1623

Rucińska T (2018) Sustainable cement mortars. In E3S Web of Conferences (Vol. 49, p. 00090). EDP Sciences

Sasiekalaa K, Malathy R (2012) Behaviour of mortar containing silica fume and fly ash. J Ind Pollut Control 28:1–7

Seeger A, Brickmann J, Luft G (2009) Penetration of organic liquids into dry Portland cement mortar under ambient and high pressure. Chem Eng Technol Ind Chem-Plant Equip-Process Eng-Biotechnol 32(6):891–902

Senin MS, Shahidan S, Leman AS, Hannan NIRR (2016) Properties of cement mortar containing rubber ash as sand replacement. In: IOP Conference Series: Materials Science and Engineering (Vol. 160, No. 1, p. 012055). IOP Publishing

Sezer Gİ (2012) Compressive strength and sulfate resistance of limestone and/or silica fume mortars. Constr Build Mater 26(1):613–618

Tashiro C, Kubota W (1976) Sulfuric acid resistance of cement mortar impregnated with pulp waste liquid. Cem Concr Res 6(6):727–732

Türkel S, Altuntaş Y (2009) The effect of limestone powder, fly ash and silica fume on the properties of self-compacting repair mortars. Sadhana 34(2):331–343

Villagrán Zaccardi YA, Fullea García J, Huélamo P, Di Maio AA (2009) Influence of temperature and humidity on Portland cement mortar resistivity monitored with inner sensors. Mater Corros 60(4):294–299

Vipulanandan C, Mohammed AS (2014) Hyperbolic rheological model with shear stress limit for acrylamide polymer modified bentonite drilling muds. J Pet Sci Eng 122:38–47

Vipulanandan C, Mohammed A (2015a) Smart cement modified with iron oxide nanoparticles to enhance the piezoresistive behavior and compressive strength for oil well applications. Smart Mater Struct 24(12):125020

Vipulanandan C, Mohammed A (2015b) Smart cement rheological and piezoresistive behavior for oil well applications. J Pet Sci Eng 135:50–58

Vipulanandan C, Mohammed A (2015c) XRD and TGA, swelling and compacted properties of polymer treated sulfate contaminated CL soil. J Test Eval 44(6):2270–2284

Vipulanandan C, Mohammed A (2015d) Effect of nanoclay on the electrical resistivity and rheological properties of smart and sensing bentonite drilling muds. J Pet Sci Eng 130:86–95

Vipulanandan C, Mohammed A (2017) Rheological properties of piezoresistive smart cement slurry modified with iron-oxide nanoparticles for oil-well applications. J Test Eval 45(6):2050–2060

Vipulanandan C, Mohammed A (2018) New Vipulanandan failure model and property correlations for sandstone, shale and limestone rocks. IFCEE 2018:365–376

Vipulanandan C, Mohammed A (2019) Magnetic field strength and temperature effects on the behavior of oil well cement slurry modified with iron oxide nanoparticles and quantified with Vipulanandan Models. J Test Eval 48(6)

Vipulanandan C, Mohammed A (2020) Effect of drilling mud bentonite contents on the fluid loss and filter cake formation on a field clay soil formation compared with the API fluid loss method and characterized using Vipulanandan models. J Pet Sci Eng:107029

Vipulanandan C, Krishnamoorti R, Mohammed A, Boncan V, Narvaez G, Head B, Pappas JM (2015) Iron nanoparticle modified smart cement for real time monitoring of ultra deepwater oil well cementing applications. In Offshore Technology Conference. Offshore Technology Conference, Houston

Vipulanandan C, Mohammed A, Samuel RG (2018a) Fluid loss control in smart bentonite drilling mud modified with nanoclay and quantified with Vipulanandan fluid loss model. In Offshore Technology Conference. Offshore Technology Conference

Vipulanandan C, Mohammed A, Ganpatye AS (2018b) Smart cement performance enhancement with NanoAl2O3 for real time monitoring applications using Vipulanandan models. In Offshore Technology Conference. Offshore Technology Conference

Yaman MA, Elaty MA, Taman M (2017) Predicting the ingredients of self-compacting concrete using artificial neural network. Alex Eng J 56(4):523–532

Yerramala AMARNATH, Desai BHASKAR (2012) Influence of fly ash replacement on strength properties of cement mortar. Int J Eng Sci Technol 4(8)

Zelić J, Krstulović R, Tkalčec E, Krolo P (2000) The properties of Portland cement-limestone-silica fume mortars. Cem Concr Res 30(1):145–152

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of Interest

The author(s) declare that they have no competing interests.

Additional information

Responsible editor: Zeynal Abiddin Erguler

Rights and permissions

About this article

Cite this article

Salih, A., Rafiq, S., Mahmood, W. et al. Various simulation techniques to predict the compressive strength of cement-based mortar modified with micro-sand at different water-to-cement ratios and curing ages. Arab J Geosci 14, 411 (2021). https://doi.org/10.1007/s12517-021-06779-z

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s12517-021-06779-z