Abstract

To accurately model warm and hot forming operations, correct values for heat transfer coefficient (HTC) are required, among other parameters. In this work, an experimental methodology is proposed to obtain HTC data for a high strength steel alloys (Usibor® 1500 A-S), seven aluminum alloys (AA5182-O, AA5754-O, AA6013-T6, AA6063-T6, AA6061-T6, AA7075-T6 and a developmental AA7xxx-T76) and two magnesium (AZ31B-O and ZEK100-O) alloys. The HTC was characterized as a function of contact pressure from 2 to 80 MPa. Overall, the HTC values exhibited significant variation (ranging from 355 to 1887 W/m2-K), but tended to correlate primarily with contact pressure and material strength/alloy system. Two lubricants were also considered (Fuchs Forge Ease 278 and PTFE spray) for some alloys, but had only a minor effect on HTC relative to “dry” tooling. Neither the initial temperature of the tooling nor the ramping up of the press tonnage had a noticeable effect on the HTC since the HTC values were identified based only upon the relative temperature difference and thermal properties of the materials. The experimentally determined HTC values were then applied in a series of non-isothermal cylindrical cup warm deep drawing experiments. The deep draws were modelled using finite element (FE) techniques, which utilized the measured HTC values. The temperature-time profiles from the deep draws were found to agree well with the predicted profiles, indicating that the methodology used to determine HTC and the resulting HTC values, are applicable for use in a metal forming simulation involving heat transfer.

Similar content being viewed by others

References

Bagheriasl R, Worswick MJ (2015) Formability of AA3003 brazing sheet at elevated temperatures: limiting dome height experiments and determination of forming limit diagrams. 229–244. https://doi.org/10.1007/s12289-014-1162-2.

Bagheriasl R, Ghavam K, Worswick MJ (2014) Formability improvement with independent die and punch temperature control. 139–154. https://doi.org/10.1007/s12289-012-1115-6.

Picu RC, Vincze G, Ozturk F, Gracio JJ, Barlat F, Maniatty AM (2005) Strain rate sensitivity of the commercial aluminum alloy AA5182-O. 390:334–343. https://doi.org/10.1016/j.msea.2004.08.029.

Ghaffari Tari D, Worswick MJ, Ali U, Gharghouri MA (2014) Mechanical response of AZ31B magnesium alloy: experimental characterization and material modeling considering proportional loading at room temperature. Int J Plast 55:247–267. https://doi.org/10.1016/j.ijplas.2013.10.006

Bergström Y, Hallén H (1982) An improved dislocation model for the stress-strain behaviour of polycrystalline c ~ -Fe. Mater Sci Eng 55(1):49–61

Rajamuthamilselvan M, Ramanathan S (2011) Hot deformation behaviour of 7075 alloy. J Alloys Compd 509(3):948–952. https://doi.org/10.1016/j.jallcom.2010.09.139

Rokni MR, Zarei-Hanzaki A, Roostaei AA, Abolhasani A (2011) Constitutive base analysis of a 7075 aluminum alloy during hot compression testing. Mater Des 32(10):4955–4960. https://doi.org/10.1016/j.matdes.2011.05.040

Liu X (2015) Determination of interfacial heat transfer coefficient of Aa7075 for hot stamping process. MATECWeb Conf 21 21:1–8

Karbasian H, Tekkaya AE (2010) A review on hot stamping. J Mater Process Technol 210(15):2103–2118. https://doi.org/10.1016/j.jmatprotec.2010.07.019.

Naderi M, Ketabchi M, Abbasi M, Bleck W (2011) Analysis of microstructure and mechanical properties of different high strength carbon steels after hot stamping. J Mater Process Technol 211(6):1117–1125. https://doi.org/10.1016/j.jmatprotec.2011.01.015

Bardelcik A, Worswick MJ, Winkler S, Wells MA (2012) A strain rate sensitive constitutive model for quenched boron steel with tailored properties. Int J Impact Eng 50:49–62. https://doi.org/10.1016/j.ijimpeng.2012.06.007

Bardelcik A, Salisbury CP, Winkler S, Wells MA, Worswick MJ (2010) Effect of cooling rate on the high strain rate properties of boron steel. Int J Impact Eng 37(6):694–702. https://doi.org/10.1016/j.ijimpeng.2009.05.009.

Merklein M, Lechler J, Stoehr T (2009) Investigations on the thermal behavior of ultra high strength boron manganese steels within hot stamping. Int J Mater Form 2(S1):259–262. https://doi.org/10.1007/s12289-009-0505-x

Eller TK, Greve L, Andres M, Medricky M, Meinders VT, Van Den BAH (2016) Journal of materials processing technology determination of strain hardening parameters of tailor hardened boron steel up to high strains using inverse FEM optimization and strain field matching. J Mater Process Technol 228:43–58. https://doi.org/10.1016/j.jmatprotec.2015.09.036.

Eller TK, Greve L, Andres MT, Medricky M, Hatscher a, Meinders VT et al (2014) Plasticity and fracture modeling of quench-hardenable boron steel with tailored properties. J Mater Process Technol 214(6):1211–1227. https://doi.org/10.1016/j.jmatprotec.2013.12.015

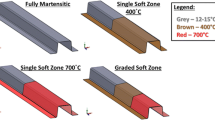

Omer K, ten Kortenaar L, Butcher C, Worswick M, Malcolm S, Detwiler D et al (2017) Testing of a hot stamped axial crush member with tailored properties – experiments and models. Int J Impact Eng 103:12–28

Liu SD, Zhang XM, Chen MA, You JH (2008) Influence of aging on quench sensitivity effect of 7055 aluminum alloy. Mater Charact 59(1):53–60. https://doi.org/10.1016/j.matchar.2006.10.019

Chen SY, Chen KH, Peng GS, Liang X, Chen XH (2012) Effect of quenching rate on microstructure and stress corrosion cracking of 7085 aluminum alloy. Trans Nonferrous Metals Soc China English Ed 22:47–52. https://doi.org/10.1016/S1003-6326(11)61138-2

Chen S, Chen K, Peng G, Jia L, Dong P (2012) Effect of heat treatment on hot deformation behavior and microstructure evolution of 7085 aluminum alloy. Mater Des 25:93–98

Garrett RP, Lin J, Dean TA (2005) Solution heat treatment and cold die quenching in forming AA 6xxx sheet components: feasibility study. Adv Mater Res 6–8:673–680. https://doi.org/10.4028/www.scientific.net/AMR.6-8.673

Garrett RP, Lin J, Dean TA (2005) An investigation of the effects of solution heat treatment on mechanical properties for AA 6xxx alloys: experimentation and modelling. Int J Plast 21(8):1640–1657. https://doi.org/10.1016/j.ijplas.2004.11.002

Shehata F, Painter MJ, Pearce R (1978) Warm forming of aluminum/magnesium alloy sheet. J Mech Work Technol 2:279–90

Naka T, Torikai G, Hino R, Yoshida F (2001) The effects of temperature and forming speed on the forming limit diagram for type 5083 aluminum - magnesium alloy sheet. J Mater Process Technol 113:648–53

Li D, Ghosh AK (2004) Biaxial warm forming behavior of aluminum sheet alloys. J Mater Process Technol 145(3):281–293. https://doi.org/10.1016/j.jmatprotec.2003.07.003

Boba M, Butcher C, Panahi N, Worswick MJ, Mishra RK, Carter JT (2015) Warm forming limits of rare earth-magnesium alloy ZEK100 sheet. Int J Mater Form 10(2):181–191. https://doi.org/10.1007/s12289-015-1267-2

Dicecco S, Butcher C, Worswick M, Boettcher E, Chu E, Shi C (2016) Determination of Forming Limit Diagrams of AA6013-T6 Aluminum Alloy Sheet using a Time and Position Dependent Localized Necking Criterion. IOP Conf Ser Mater Sci Eng 159. https://doi.org/10.1088/1757-899X/159/1/012009

Dicecco S, Butcher C, Worswick M, Chu E, Shi C (2016) Application of Time and Position Dependent Localized Necking Criteria to High Strength Aluminum Alloys at Elevated Temperatures. Proc from Form Technol Forum

Abedrabbo N, Pourboghrat F, Carsley J (2007) Forming of AA5182-O and AA5754-O at elevated temperatures using coupled thermo-mechanical finite element models. Int J Plast 23(5):841–875. https://doi.org/10.1016/j.ijplas.2006.10.005

Hsu E, Carsley JE, Verma R (2008) Development of forming limit diagrams of aluminum and magnesium sheet alloys at elevated temperatures. J Mater Eng Perform 17(3):288–296. https://doi.org/10.1007/s11665-007-9196-y

Caron EJFR, Daun KJ, Wells MA (2014) Experimental heat transfer coefficient measurements during hot forming die quenching of boron steel at high temperatures. Int J Heat Mass Transf 71:396–404. https://doi.org/10.1016/j.ijheatmasstransfer.2013.12.039.

Caron E, Daun KJ, Wells MA (2013) Experimental characterization of heat transfer coefficients during hot forming die quenching of boron steel. Metall Mater Trans B Process Metall Mater Process Sci 44(2):332–343. https://doi.org/10.1007/s11663-012-9772-x

Malinowski Z, Lenard JG, Davies ME (1994) A study of the heat-transfer coefficient as a function of temperature and pressure. J Mater Process Technol 41(2):125–142. https://doi.org/10.1016/0924-0136(94)90057-4

Prajogo Y (2015) Hot stamping of a boron steel side impact beam with tailored flange properties. University of Waterloo

George R, Bardelcik a, Worswick MJ (2012) Hot forming of boron steels using heated and cooled tooling for tailored properties. J Mater Process Technol 212(11):2386–2399. https://doi.org/10.1016/j.jmatprotec.2012.06.028

Ghosh M, Miroux a, Werkhoven RJ, Bolt PJ, Kestens L a I (2014) Warm deep-drawing and post drawing analysis of two Al-Mg-Si alloys. J Mater Process Technol 214(4):756–766. https://doi.org/10.1016/j.jmatprotec.2013.10.020

Toros S, Ozturk F, Kacar I (2008) Review of warm forming of aluminum–magnesium alloys. J Mater Process Technol 207(1-3):1–12. https://doi.org/10.1016/j.jmatprotec.2008.03.057

Tanner DA, Robinson JS (2000) Residual stress prediction and determination in 7010 aluminum alloy forgings. Exp Mech 40(1):75–82. https://doi.org/10.1007/BF02327551

Sarmiento GS, Coscia DM, Totten GE, Jouglard C, Webster GM, Vega J (2000) Residual Stresses , Distortion and Heat Transfer Coefficients of 7075 Aluminum Alloy Probes Quenched in Water and Polyalkylene Glycol Solutions. Heat Treat – Proc 20th Conf 2, Eds K Funatani GE Totten, ASM Int Mater Park 9–12 October, 1118–24

Ji K, El Fakir O, Gao H, Wang L (2015) Determination of heat transfer coefficient for hot stamping process. Mater Today Proc 2:S434–S439. https://doi.org/10.1016/j.matpr.2015.05.059

Bramley AN, Chang CC (2002) Determination of the heat transfer coefficient at the workpiece—die interface for the forging process. Proc Inst Mech Eng Part B J Eng Manuf

Abdul Hay B, Bourouga B, Dessain C (2010) Thermal contact resistance estimation at the blank/tool interface: experimental approach to simulate the blank cooling during the hot stamping process. Int J Mater Form 3(3):147–163. https://doi.org/10.1007/s12289-010-0687-2

Hung TH, Tsai PW, Chen FK, Bin HT, Liu WL (2014) Measurement of heat transfer coefficient of boron steel in hot stamping. Procedia Eng 81:1750–1755. https://doi.org/10.1016/j.proeng.2014.10.226

Bosetti P, Bruschi S, Stoehr T, Lechler J, Merklein M (2010) Interlaboratory comparison for heat transfer coefficient identification in hot stamping of high strength steels. Int J Mater Form 3(S1):817–820. https://doi.org/10.1007/s12289-010-0895-9

Zhang Z, Gao P, Liu C, Li X (2015) Experimental and simulation study for heat transfer coefficient in hot stamping of high-strength boron steel. Metall Mater Trans B Process Metall Mater Process Sci 46(6):2419–2422. https://doi.org/10.1007/s11663-015-0452-5

Chang Y, Tang X, Zhao K, Hu P, Wu Y (2016) Investigation of the factors influencing the interfacial heat transfer coefficient in hot stamping. J Mater Process Technol 228:25–33. https://doi.org/10.1016/j.jmatprotec.2014.10.008

Wiskel JB (1995) Thermal Analysis of the Startup Phase for D.C. Casting of an AA5182 Aluminum Ingot. University of British Columbia

Summers PT, Chen Y, Rippe CM, Allen B, Mouritz AP, Case SW, Lattimer BY (2015) Overview of aluminum alloy mechanical properties during and after fires. Fire Sci Rev 4(1):3. https://doi.org/10.1186/s40038-015-0007-5

Jeanmart P, Bouvaist J (1985) Finite element calculation and measurement of thermal stresses in quenched plates of high–strength 7075 aluminium alloy. Mater Sci Technol 1(10). https://doi.org/10.1179/mst.1985.1.10.765

Tari DG (2014) Room and elevated temperature constitutive response of polycrystalline materials exhibiting tension-compression asymmetry under monotonic loading. University of Waterloo

ASM International (1990) Asm Handbook: Properties and Selection: Irons, Steels, and High Performance Alloys, 10th edn. ASM International, Materials Park

Livermore Software Technology Corporation (LSTC) (2011) Keyword user ’ S manual volume 1. vol. I. Livermore, CA, USA

Livermore Software Technology Corporation (LSTC) (2014) Keyword user ’ S manual volume II. vol. II. Livermore, CA, USA

Beer FP, Johnstron ER, DeWolf JT, Mazurek DF (2012) Mechanics of materials, 6th edn. McGraw Hill, New York City

Touloukian YS (1970) Thermophysical properties of matter. IFI/Plenum

Zhang H, Nagaumi H, Zuo Y, Cui J (2007) Coupled modeling of electromagnetic field, fluid flow, heat transfer and solidification during low frequency electromagnetic casting of 7XXX aluminum alloys: part 1: development of a mathematical model and comparison with experimental results. Mater Sci Eng A 448(1-2):189–203. https://doi.org/10.1016/j.msea.2006.10.062.

(2015) Standard Test Methods for Tension Testing of Metallic Materials - ASTM Standard E8 / E8M - 15a

Standard Test Methods for Tension Testing of Metallic Materials (2015)

(2013) Correlated Solutions. Vic 3D

Omer K, Kim S, Butcher C, Worswick M (2017) Characterizing the constitutive properties of AA7075 for hot forming. J Phys Conf Ser, vol. 896, Munich, Germany. https://doi.org/10.1088/1742-6596/896/1/012054

Barlat F, Lian K (1989) Plastic behavior and stretchability of sheet metals. Part I: a yield function for orthotropic sheets under plane stress conditions. Int J Plast 5(1):51–66. https://doi.org/10.1016/0749-6419(89)90019-3

Tajally M, Emadoddin E (2011) Mechanical and anisotropic behaviors of 7075 aluminum alloy sheets. Mater Des 32(3):1594–1599. https://doi.org/10.1016/j.matdes.2010.09.001

Khan AS, Baig M (2011) Anisotropic responses, constitutive modeling and the effects of strain-rate and temperature on the formability of an aluminum alloy. Int J Plast 27(4):522–538. https://doi.org/10.1016/j.ijplas.2010.08.001

Li D, Ghosh A (2003) Tensile deformation behavior of aluminum alloys at warm forming temperatures. Mater Sci Eng A 352(1-2):279–286. https://doi.org/10.1016/S0921-5093(02)00915-2

Shapiro AB (2008) Using LS-DYNA to model hot sheet metal stamping. 1st Int. Conf. Hot Sheet Met. Form. High-Performance Steel, Kassel, Germany

Jain VK (1990) Determination of heat transfer coefficient for forging applications. J Mater Shap Technol 8(3):193–202. https://doi.org/10.1007/BF02833814

Liu X, Ji K, El FO, Fang H, Gharbi MM, Wang LL (2017) Determination of the interfacial heat transfer coefficient for a hot aluminium stamping process. J Mater Process Technol 247:158–170. https://doi.org/10.1016/j.jmatprotec.2017.04.005

Noder J, DiCecco S, Butcher C, Worswick M (2017) Finite element simulation of non-isothermal warm forming of high-strength aluminum alloy sheet, 080017. https://doi.org/10.1063/1.5008097

Acknowledgements

The authors are very grateful for Prof. Kyle Daun for providing his insight and expertise on the heat transfer topic.

Funding

The authors would like to thank Honda R&D Americas Inc., Arconic Ground Transportation Group, Promatek Research Centre, the Natural Sciences and Engineering Research Council (NSERC), the Canada Foundation for Innovation, the Ontario Research Fund and the Canada Research Chairs Secretariat for supporting this research.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Omer, K., Butcher, C. & Worswick, M. Characterization of heat transfer coefficient for non-isothermal elevated temperature forming of metal alloys. Int J Mater Form 13, 177–201 (2020). https://doi.org/10.1007/s12289-019-01478-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12289-019-01478-3